Environmental

-

Water

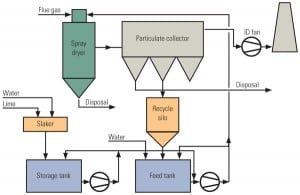

Circulating Fluid Bed Scrubbers Bridge the Gap Between Dry and Wet Scrubbers

Circulating fluid bed (CFB) dry scrubbing technologies provide distinct advantages over conventional spray dryer absorber scrubbers for removing SO2 from flue gases. The CFB also competes well against wet limestone flue gas desulfurization processes typically favored for large boilers firing high-sulfur coals. With high SO2 removal rates in a dry treatment process, the CFB scrubber appears to be the best of both technologies: a water-stingy scrubber with high SO2 removal rates.

-

Coal

Drax Offers Model for Cofiring Biomass

When it is completed, later this summer, the UK’s Drax Power Station biomass facility will become the largest dedicated cofiring project of its kind in the world. As U.S. coal-fired generators come under increasing pressure to cut emissions and take advantage of incentives to promote power generation from renewables, Drax offers an example of what is possible.

-

Environmental

Regulations and Economics Drive Wet FGD Upgrades

Today’s coal-fired power plants face the twin challenges of improving their wet flue gas desulfurization (FGD) systems’ emission control capabilities in order to comply with environmental regulations while at the same time cutting their operational and maintenance costs. Smart strategies for retrofitting existing FGD systems can help plant personnel meet both of these objectives.

-

Coal

Industry Pivots on Natural Gas, Hails Cap and Trade

At the opening ELECTRIC POWER 2010 plenary session, both the keynote speaker’s address and discussion among the Power Industry Executive Roundtable participants pointed to the renewed appeal of natural gas and proposed cap-and-trade legislation as being potential game-changers for the U.S. power industry.

-

Environmental

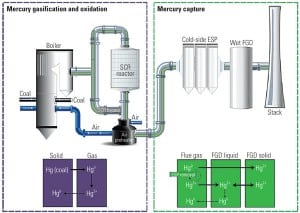

Determining AQCS Mercury Removal Co-Benefits

The U.S. Environmental Protection Agency is expected to propose an emissions standard for mercury and other hazardous air pollutants emitted by coal- and oil-fired electric generating units in March of 2011. The anticipated rule would require emission control to meet the various standards using maximum achievable control technology, as determined by the prescriptive requirements of the Clean Air Act. In response to the expected rule-making, utilities will be required to make technology decisions in order to ensure compliance. One cost-effective approach to compliance may be the use of “co-benefits” from air quality control systems (AQCSs) already in service that are designed to remove other pollutants.

-

Coal

EPA Proposes Two Options to Regulate Coal Ash

In an unusual two-option proposal that drew clashing views from green groups and power plant operators, the Environmental Protection Agency has proposed regulating coal combustion ash either as a nonhazardous waste subject to tougher management and disposal requirements or as a "special" hazardous waste that would have similar controls but still be eligible for recycling and reuse in products such as Portland cement.

-

Coal

EPA Issues Final Greenhouse Gas Tailoring Rule

Less than 24 hours after the unveiling of sweeping Senate legislation to reduce U.S. greenhouse gas emissions, the Environmental Protection Agency released a final Clean Air Act rule that defines emission thresholds for greenhouse gas permitting requirements for power plants and other large stationary sources.

-

Coal

American Power Act Dangles Carrots for Nukes, Coal, Gas

Facing a difficult uphill slog in a sharply polarized Senate, Sens. John Kerry and Joseph Lieberman have unveiled long-awaited draft climate change and energy legislation that includes billions of dollars in incentives for the nuclear, natural gas, and coal industries aimed at attracting enough bipartisan support to overcome an all-but-certain filibuster led by the Senate Republican leadership.

-

Commentary

Power Industry Flip-Flops on Support of Carbon Controls

I recently had the privilege of moderating the Power Industry Executive Roundtable, part of the annual ELECTRIC POWER Conference & Exhibition opening ceremonies. Usually, the power industry executives have predictable views of important issues, but not this year.

-

Environmental

Dry Injection of Trona for SO3 Control

In 2006 and 2007, POWER ran a three-part series on the formation of SO3, O&M issues caused by SO3, and sorbent injection control for SO3 control. Three years later, many plants still struggle with their SO 3 mitigation systems or remain undecided on which mitigation path to follow. This article explores the advantages of dry sorbent injection technology.