Coal

-

Coal

J.K. Spruce Power Plant, Unit 1, San Antonio, Texas

Top Plant: CPS Energy’s J.K. Spruce Power Plant, Unit 1 was recently recognized by the EUCG Fossil Productivity Committee as the best performer in the large coal plant category over the 2002-2006 evaluation period. The competition was tough, with more than 80 plants in the running, but Unit 1 emerged as the clear winner by earning top points for high plant reliability and very low nonfuel O&M costs.

-

Coal

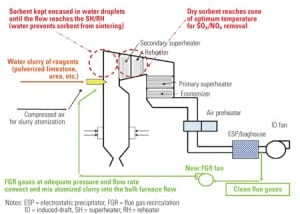

Bringing down the cost of SO2 and NOx removal

A twist on an old technique, flue gas recirculation, helps prevent slagging in the upper furnace and convective pass, according to pilot testing recently completed by APTECH CST and the Southern Research Institute. The technology—along with a companion technology for furnace sorbent and urea injection for SO2 and NOx control—could help owner/operators of smaller, older coal-fired plants meet emissions limits at a reasonable cost.

-

Coal

Finessing fuel fineness

Most of today’s operating coal plants began service at least a generation ago and were designed to burn eastern bituminous coal. A switch to Powder River Basin coal can stress those plants’ boiler systems, especially the pulverizers, beyond their design limits and cause no end of operational and maintenance problems. Many of those problems are caused by failing to maintain good fuel fineness when increasing fuel throughput.

-

Coal

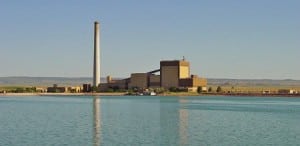

TS Power Plant, Eureka County, Nevada

Top Plant: Not all coal-fired power plants are constructed by investor-owned utilities or independent power producers selling to wholesale markets. When Newmont Mining Corp. recognized that local power supplies were inadequate and too expensive to meet long-term electricity needs for its major gold- and copper-mining operations in northern Nevada, it built its own generation. What’s more, Newmont’s privately owned 200-MW net coal-fired plant features power plant technologies that will surely become industry standards. Newmont’s investment in power and technology is also golden: The capital cost will be paid back in about eight years.

-

Coal

Rawhide Energy Station, Fort Collins, Colorado

Top Plant: The staff of the Rawhide Energy Station have been racking up operating stats and an environmental performance record that is the envy of other plant managers. In the past decade Rawhide has enjoyed an equivalent availability factor in the mid- to high 90s and an average capacity factor approaching 90%. Still not content with this performance, Rawhide invested in new technology and equipment upgrades to further optimize performance, reduce emissions, and keep cost competitive.

-

Coal

Map of Coal-fired Power Plants in the United States

Courtesy: Platts Data source: Platts Energy Advantage and POWERmap. All rights reserved.

-

Coal

Boryeong Thermal Power Complex, Boryeong-Si, Chungcheongnam-do Province, South Korea

Top Plant: From tall skyscrapers and flashing neon signs to Buddhist temples and pagodas, South Korea is a mixture of the new and old Asia. Doing its part to help modernize this country, the Boryeong Thermal Power Complex operates six coal-fired 500-MW units that provide electricity to power South Korea’s economic growth. One of the important reasons for this facility’s overall success is its operational reliability. An example of this is Boryeong Unit 3’s outstanding achievement of 3,000 days of trouble-free operation.

-

Coal

Dubuque Generating Station, Dubuque, Iowa

Top Plant: Alliant Energy’s Dubuque Generating Station is a fine example of why small doesn’t mean insignificant in the power generation industry. This winner of the EUCG Best Performer award in the small plant category shows that its operating excellence towers over that of many larger and much newer coal-fired power plants.

-

Coal

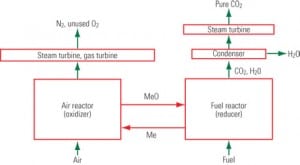

Chemical looping and coal

What does human metabolism have in common with coal combustion? Quite a bit, it turns out, say researchers at the National Energy Technology Laboratory (NETL) who are studying chemical looping combustion (CLC) involving coal gasification, an emerging technology for clean energy production from fossil and renewable fuels.

-

Coal

Computer simulation as a NOx reduction design tool

A utility evaluated various methods of obtaining a NOx reduction of at least 30%, as required by upcoming regulations for its boiler, which originally produced 0.54 lb of NOx/million Btu at 410 MW full load. Nalco Mobotec engineers performed a computational fluid dynamics (CFD) simulation of the boiler to first understand the boiler’s combustion process and then determine the most economical method to achieve the required NOx reduction.