-

O&M

Projects

Kansas City Power & Light Installing SCR at La Cygne Generating Station Kansas City Power & Light (KCP&L), a subsidiary of Great Plains Energy, has awarded The Babcock & Wilcox Company (B&W) a contract for the installation of new emissions control equipment on Unit 1 at its La Cygne Generating Station. When completed, the selective […]

-

Coal

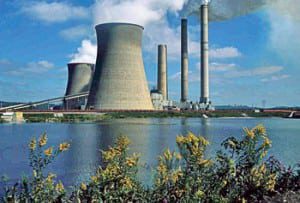

Pollution-Control Technologies: Multi-Pollutant Removal Systems Are a Clean Coal Technology

The first power plants were built about 130 years ago. Coal was then, and is still today, the major fuel used for power generation. Currently, about 1,400 pulverized coal – fired units, with an average age of more than 30 years, generate over 50% of U.S. electric power. The use of low-sulfur coal and improved […]

-

Coal

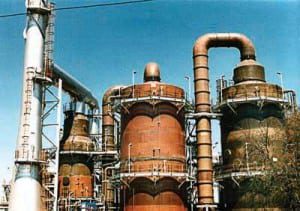

Curbing the blue plume: SO3 formation and mitigation

Understanding why stack emissions become opaque leads to better choices of systems for controlling SO3 and other pollutants, based on current and future plant operating configurations.

-

Coal

How accurate primary airflow measurements improve plant performance

Primary airflow has a major impact on the efficiency, capacity, and cleanliness of pulverized coal–fired generation. Inaccurate measurements that underestimate primary airflow levels can lead to negative operational outcomes that include increased boiler gas temperatures, flyash loss-on-ignition, excessive NOx emissions, and higher-than-necessary fan power consumption. We remind you how to avoid those headaches.

-

Gas

Cheng Cycle flirts with 2 ppm NOx— and CO

Three years ago, an article in POWER described how Cheng Power Systems, by modifying the combustors of several popular gas turbines, had used steam injection to lower the units’ NOx output to about 5 ppm—but some models had substantial CO levels without combustor modifications. Since then, the company has developed new combustor nozzles that recently […]

-

Coal

Designing and maintaining steam coil air preheaters for reliability and effectiveness

If engineered well and drained properly, a simple finned-tube heat exchanger can help maximize a fossil-fueled power plant’s combustion efficiency, capacity, and air pollution reduction. Use the guidelines in this article either to return a disabled steam coil air preheater to service or to improve the performance of a unit that may have been wasting […]

-

Instrumentation & Controls

Solving plant vibration problems

Solving insidious vibration problems in rotating equipment may sometimes seem like a black art that requires the right incantation. But identifying the root cause of the vibration is actually a science. By using cutting-edge vibration measurement tools in concert with computer simulations, plant operators can arrive at a permanent, cost-effective solution to virtually any vibration […]

-

Gas

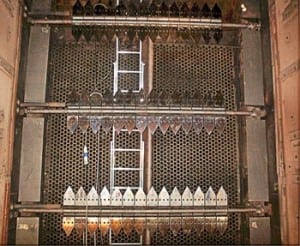

Designing duct burners for variable GT loads

Duct burners use supplementary firing to increase the heat energy of a gas turbine’s exhaust, making it possible to increase the output of a downstream heat-recovery steam generator (HRSG). Early systems of the 1960s took a conventional approach to burner design. The exhaust of the turbine was directed into a windbox and then into a […]

-

Wind

Greener than thou

U.S. wind power is on a roll, with wind farms sprouting like weeds. But in the near future, utilities may end up paying higher prices for wind capacity because state regulators are, in effect, imposing an artificial floor on national demand for generation fueled by renewable resources. At last count, at least 20 states had […]

-

Gas

Global Monitor (May 2006)

Nuclear hot streak continues/Who’s winning in U.S. wind power?/ Canadian wind picking up too/ Brazilian port powers itself/ Biomass meets CHP in Sweden/ Power surfing from Scotland to Germany

Search