-

Water

Readers Write

In the September and October 2010 issues, POWER Contributing Editor David Daniels explored the causes and damage mechanisms of condenser tube leaks (“Taming Condenser Tube Leaks,” Part I and Part II). Dennis J. Schumerth, Valtimet’s director of business development, took issue with several of Daniels’ statements regarding the proper use of titanium condenser tubes. We have given Schumerth the opportunity to express his concerns and for Daniels to reply.

-

Commentary

EPA Expands Climate Agenda to the Current Fleet of Power Plants and Refineries

On December 23, 2010, one day before the Yuletide season, when members of Congress, the media, and Tea Party activists are least likely to watchdog the federal bureaucracy, the U.S. Environmental Protection Agency (EPA) announced rulemakings to establish New Source Performance Standards (NSPS) for greenhouse gas (GHG) emissions from power plants and refineries. Or maybe "whispered" would be more accurate.

-

O&M

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

Business

POWER Digest (Feb. 2011)

MHI to Continue Pre-Construction Work for North Anna Unit. Mitsubishi Heavy Industries Ltd. (MHI), through Mitsubishi Nuclear Energy Systems Inc., and Dominion subsidiary Virginia Electric and Power Co. on Dec. 27 said they had reached an agreement to continue pre-construction, engineering, and planning work in preparation for a third unit at Dominion’s North Anna Nuclear […]

-

O&M

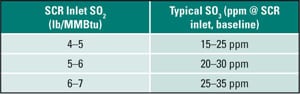

Continuous SO3 Monitoring Can Reduce Sorbent Consumption

An unintended consequence of employing selective catalytic reduction and wet flue gas desulfurization to reduce nitrogen oxide and sulfur dioxide levels at coal-fired power plants has been unwanted sulfur trioxide (SO3) emissions. Picking the right sorbent in the right amount can eliminate that problem.

-

Nuclear

I&C Update on Plant Vogtle Units 3 and 4

Development of Vogtle Electric Generating Station Units 3 and 4—the first new nuclear power plant units in the U.S. in decades—has generated considerable excitement. The next generation of nuclear plants, represented by these units, includes at least two major improvements: the use of passive safety systems and a reliance on digital control systems. The latter represents a gigantic leap in modernization and a fundamental change in control of the plant.

-

O&M

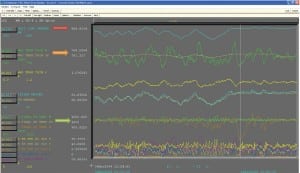

New Tools for Diagnosing and Troubleshooting Power Plant Equipment Faults

The Electric Power Research Institute has developed a pair of diagnostic tools that combine and integrate features from multiple sources of plant information. The Diagnostic Advisor and the Asset Fault Signature Database will improve diagnostics for and troubleshooting of equipment faults by providing a holistic view of the condition of plant equipment.

-

Gas

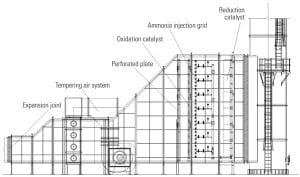

Automated Exhaust Temperature Control for Simple-Cycle Power Plants

A common concern for gas turbine power plants is treating exhaust gases to comply with laws restricting pollutants present in the gases that are emitted into the ambient atmosphere. The challenge for designers is to control the exhaust gas operating temperature within a range that maximizes performance of the oxidation and reduction catalysts.

-

Instrumentation & Controls

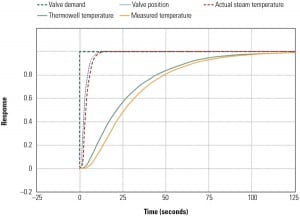

Thermocouple Response Time Study for Steam Temperature Control

One important factor in power plant control system performance is the response time of the process measurement used in the control system. The response time of boiler steam temperature sensors and thermowells is examined, as is those sensors’ and thermowells’ effect on desuperheater temperature response time and, therefore, steam temperature control performance.

-

Instrumentation & Controls

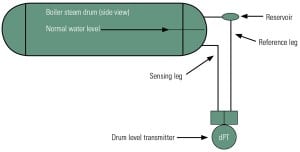

Concerns About Temperature-Equalizing Columns Used for Steam Drum Level Measurement

In the 1950s, temperature-equalizing columns were commonly used in steam drum differential pressure–based devices for measuring water level. However, these columns are problematic because a portion of the reference leg can flash to steam on a pressure decrease (load increase), and this will result in a temporary, false, high-level measurement, which adds to the swell effect. The columns can also result in measurement inaccuracies. It’s time to replace these antiquated instruments with a more modern reference leg.

Search