This is an online supplement to the feature story “The Need for Alternate PM2.5 Emission Factors for Gas-Fired Combustion Units” in the July 2015 issue of POWER.

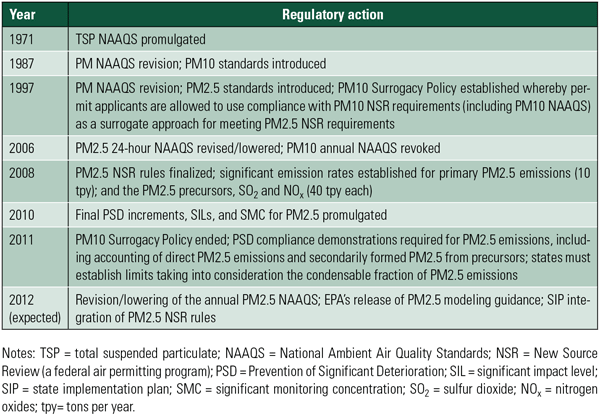

The history of in-stack PM measurement methods began in 1971 with promulgation of the U.S. Environmental Protection Agency (EPA) Reference Method 5, following on the heels of promulgation of the National Ambient Air Quality Standards (NAAQS) for total suspended particulate matter (PM) earlier that same year.

In 1978, the EPA promulgated Reference Method 17 as an alternative method for measuring PM, where the stack gas PM concentration is known to be independent of temperature. Both Methods 5 and 17 rely on a filter media to capture PM for emissions quantification, thus measuring the filterable PM component of emissions.

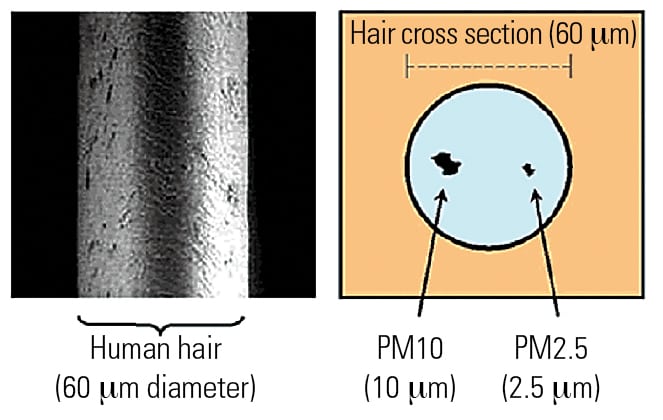

With promulgation of the NAAQS for PM with a diameter of less than or equal to 10 micrometers (PM10) in 1987, a new method was needed to quantify PM10 emissions specifically, because Methods 5 and 17 provided a PM measurement that included all size fractions. Therefore, in April 1990, the EPA promulgated Reference Method 201/201A as the stack test method for filterable PM10. (See 40 CFR Part 51, Appendix M.)

The agency recognized that condensable PM emissions can be a significant fraction of the actual total PM10 emissions from combustion sources that needed to be measured and accounted for in air quality analyses. As a result, in December 1991, it promulgated Reference Method 202. (See 40 CFR Part 51, Appendix M.) Method 202 is typically used in conjunction with Method 5 or Method 201A to measure total (filterable plus condensable) PM. The Method 202 apparatus, with its out-of-stack condensable PM filter and collection impingers, actually is in the rear of the Method 5 or 201A sampling equipment assembly.

In the originally promulgated version of Method 202, exhaust gases were bubbled through water-filled impingers, with the solution being analyzed in a laboratory to quantify the organic and inorganic material fractions of the condensed PM. However, numerous studies conducted both inside and outside the EPA indicated that noncondensable gases (such as sulfur dioxide) could react in the water solution to form condensable PM (such as sulfates) that would not have otherwise formed in the stack. The formation of this sulfate artifact or “pseudo-particulate” resulted in significant overestimates of condensable PM emissions.

Promulgation of the PM2.5 NAAQS in 1997 and revised, more restrictive PM2.5 NAAQS in 2006 provided increased impetus to improve stack gas PM measurement methods for the smaller size fraction, especially given the increasing number of gas-fired sources that emit PM at very low levels. As a result, in December 2010, the EPA promulgated revised versions of Methods 201A and 202.

Changes to Method 201A involved mainly hardware, most notably adding a PM2.5 cyclone and a PM2.5 filter after the PM10 cyclone to enable the measurement of filterable PM2.5 in addition to filterable PM10. Method 202 was modified to incorporate a condenser and “dry impinger” set-up in the back half of the sampling train. Also, Method 202 sample recovery and processing procedures were revised, mainly to make existing optional procedures in the method mandatory. The revised version of Method 202 ensures consistency of method application and is intended to improve measurement precision by reducing sulfate artifact formation. EPA research studies showed that these revisions to Method 202 should reduce sulfate artifact formation by at least 90% (75 FR 80118).

On April 8, 2014, the EPA issued interim guidance that addressed the processing of Method 202 results for regulatory permitting and compliance purposes. The focus of the guidance was on the treatment of field train blanks, which are used by testing firms to assess potential sample contamination and determine if measurement “corrections” are necessary. The interim guidance essentially allows for a higher maximum correction level, if dictated by the appropriate blank value, with the intent of reducing overestimation of condensable PM emissions.

—Louis Corio (lcorio@zephyrenv.com) is a senior technical specialist at Zephyr Environmental Corp., Columbia, Md., and Karen Olson (kolson@zephyrenv.com) is a principal at Zephyr Environmental Corp., Austin, Texas.