China’s installed wind power capacity has doubled for six consecutive years. However, along with the increased capacity come wind power accidents, incidents, and failures. Considering the sharply rising amount of wind power, the authors examine and sort wind technology failures by type and explore their causes in an effort to offer solutions.

China has abundant and readily developable wind resources. According to relevant data, the exploitable on-land wind energy resource represents a power generation capacity of 2,380 GW; the off-shore wind energy resource is around 200 GW. China’s wind resource is centralized, and the wind energy potential of the “three-north area” (composed of north, northeast, and northwest China) as well as the country’s southeast coastline and islands along the coast accounts for 80% of that potential. The geographic distribution of the wind resource somewhat coincides with China’s coal resource, although it is generally not coincident with load.

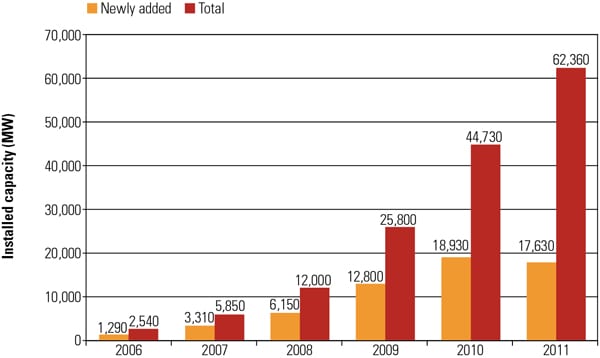

In 2011, some 11,409 wind turbines were installed in China (excluding Taiwan), representing 17.63 GW of installed capacity. By the end of 2011, the total capacity of wind turbines in China equaled 62.36 GW, representing an annual growth rate of 39.4% (Figure 1).

|

| 1. Growing wind capacity. Newly added and total installed capacity in China between 2006 and 2011. Source: North China Electric Power University |

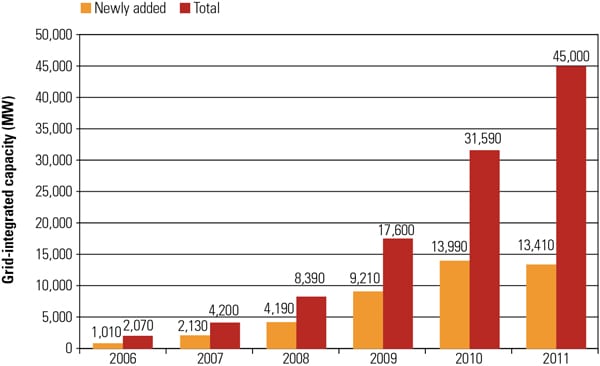

Compared with installed capacity, grid-integrated capacity and grid-integrated output are more effective ways to measure the quality of China’s wind power industry growth. With the development of advanced technology, grid-integrated capacity is increasing annually, and rose from almost 31.6 GW in 2010 to 45 GW in 2011 (Figure 2).

|

| 2. Grid-integrated wind capacity. Newly added and total grid-integrated wind generating capacity in China between 2006 and 2011. Source: North China Electric Power University |

The rate of growth in the development of wind power is slowing, but grid-integrated capacity is increasing, which indicates that the number of projects not integrated with the grid is falling. This suggests that China’s wind power industry is developing in a healthy way, albeit gradually.

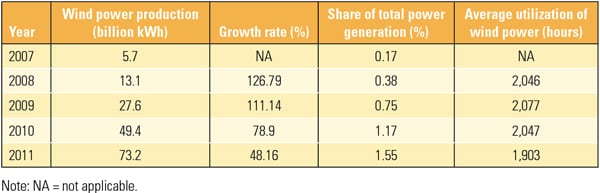

As grid-integrated capacity rises, so too does wind power production. In 2007 wind generated 5.7 billion kWh and accounted for 0.17% of China’s total power production. As the table shows, by 2011 wind power production stood at 73.2 billion kWh and accounted for 1.55% of the country’s total electricity production.

Wind Power Incidents in China

The rapid pace of wind power development in China has brought with it issues such as excess capacity, difficulties in grid integration, and myriad problems associated with quality. These issues could impede developing still more wind power. Data analysis suggests that wind power incidents may be divided into two classes: trip accidents and equipment faults.

Turbine trip incidents are very common. In 2010, there were 80 trip incidents, 15 of which resulted in the loss of 100 MW to 500 MW of electricity. In 2011, 193 turbine trip incidents occurred between January and August, of which 54 resulted in the loss of 100 MW to 500 MW of capacity. Another 12 incidents resulted in the loss of more than 500 MW of capacity.

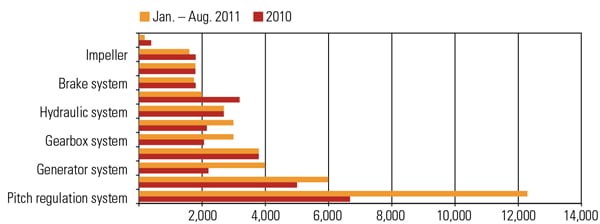

An analysis of statistics related to equipment faults among wind-power companies shows that starting in 2010, the number of wind turbine faults has been increasing. Parts such as the pitch system, frequency conversion system, electrical system, control system, gearbox, generator, and yaw systems have been affected, as shown in Figure 3.

|

| 3. Wind turbine accident classifications. Parts such as the pitch system, frequency conversion system, electrical system, control system, gearbox, generator, and yaw systems have been most affected. Source: North China Electric Power University |

|

| Wind power production in China 2007–2011. Wind power’s share of total energy production has risen in recent years, but it remains a small part of China’s overall generation mix. Source: China National Electric Power Industry Statistics Bulletin |

The technical performance of some wind turbines falls short of meeting the requirements of safe grid integration. In particular, most turbines that have been put into use do not have low-voltage ride-through capability. Efforts aimed at improving this capability have been hampered because many wind farms lack a retrofit plan. This failure to plan for low-voltage ride-through has resulted in seemingly endless arguments about retrofit fees and has led to shelving some reconstruction plans altogether.

Retrofit fees can be high, putting great pressure on operators; it’s also not easy to prepare a reconstruction plan. For those turbines that were put into service early on and whose capacity is below 1 MW, technical difficulties exist concerning their reconstruction. Furthermore, some wind farms are poorly managed, and many managers are afraid of reconstruction. As a result, a few wind farms have stated that they could not complete reconstruction until 2014; a few wind farms are not studying the issue at all.

A second issue involves reactive power compensation devices in some wind farms that could not satisfy grid safety operation requirements. Most wind farm turbines either are not capable of regulating reactive power dynamically or their capacity and regulation speed are incapable of satisfying grid operation requirements. In a few instances, reactive power compensation devices are absent altogether or older devices are running with a fixed capacitor (reactance) group, which requires operation that does not regulate voltage automatically. Other wind turbines have limited systematic voltage regulation capabilities. Wind turbine monitoring systems provided by manufacturers often do not offer access to users or are not capable of regulating power factors online. Hence, turbines cannot effectively manage voltage regulation, which increases the difficulty of systematic reactive regulation and leads to some wind farms being equipped with more reactive devices than necessary.

A third issue is construction faults in the design of some wind farms. For example, 35-kV collector systems in some wind farms are designed by mechanically referring to the design standard of the conventional distribution network, which results in using improper grounding methods. As a result, operators are unable to quickly cut off the selected line when there is single phase fault, which may lead to accidents and grid disconnection. In addition, the type of step-up transformer chosen is based on selected distribution network design principles; package transformers are widely adopted and more cable terminations are used than are necessary. As a result, cable termination fault becomes a main cause leading to wind farm accidents.

In China’s southeast coastal areas, wind turbines in some instances are installed without considering microsite factors, which may affect turbine safety and performance. As a result, when typhoons create strong turbulence, equipment accidents occur, such as collapsed towers and broken blades. Other design problems include improperly positioned leading wire and improperly secured cable structures, which can lead to excessive vibration in high winds.

In other cases, major construction quality deficiencies exist. This is the result of some wind farm construction organizations focusing mainly on expediting development while putting little thought into management. Specifically, quality, testing, control, and acceptance inspections are not carried out in strict accordance with the rules. What’s more, some developers do not have effective control and management over construction quality. In some cases, unqualified organizations perform the primary work.

Recently, more wind power equipment manufacturers are starting up in China; their number currently stands at more than 80. To reduce costs, a few manufacturers have adopted low-cost components, which reduce equipment quality even as they reduce expenses. What’s more, some domestic wind turbines are put into use without field operation tests; hence, turbine accidents typically occur during construction or soon after the machines are put into use. In some instances, the entire turbine falls down, the main shaft breaks, the motor catches fire, the gearbox becomes damaged, and blades rupture.

At present, China’s wind power system is not sound, and technical standards lag far behind those in other nations. National technical standards have not been set, and technical standards for the centralized control of wind farms—along with standards for system design, integration, and monitoring—are still on the way.

Solutions and Suggestions

Given the problems outlined above, China should endeavor to take action toward the following three goals.

Strengthen Research on Key Technology and Perfect Wind-Equipment Manufacturing Industry Policies to Comprehensively Improve Manufacturing. Industry policy improvements are required to make the equipment manufacturing industry avoid irrational competition. Strict equipment manufacturing standards and authentication systems should be established, and wind turbine series directories and standard accessories should be set up to guide orderly research and development.

Efforts should be made to strengthen research efforts on key pieces of equipment with more investment devoted to technology innovation. As a start, China should arrange a series of major projects in wind power manufacturing to improve wind turbine design and development with an eye toward reliable and stable operations.

China Should Adopt a Comprehensive Approach to Wind Resource Planning. As a first step, policies should encourage taking a comprehensive approach to wind power and the construction of transmission lines. China should keep a balance and a connection between wind power development and the grid’s construction. In areas where wind resources are abundant, grid construction should be enhanced and attention should be paid to improving the grid to meet the requirements of wind power development. Moreover, China needs to strengthen the construction of tie-lines between provinces to improve transmission as well as the grid’s ability to accept wind power.

As a second step, China must better integrate wind power, peaking power supplies, and frequency-tuned (frequency regulation) power supplies. The construction of flexible, dispatchable power sources such as pumped-storage power plants, gas-fired plants, and conventional hydropower plants should be speeded up, and fossil-fueled plants could be encouraged to take part in peak-regulating operations. What’s more, policies aimed at linking renewable energy and frequency-tuned power sources should be carried out to promote the coordinated development of wind power, thermal power, and hydropower. These could be further expanded to meet the demand of large-scale grid integration.

As a third step, China should take a comprehensive view of economic development and wind power development planning to ensure resources are developed on the basis of available wind resources and local load. China also needs to make the location of energy-loaded industries compatible with those areas rich in wind resources.

As a fourth step, China needs to add more ways to consume wind power at its point of production. China should combine both distributed and centralized wind power, encourage areas to utilize distributed wind power, strengthen the construction of distribution networks, and improve in-situ wind power consumption. Furthermore, China needs to strengthen demand-side management in areas rich in wind power, improve load characteristics, and encourage and use smart grid technologies to promote the consumption of wind power.

As a fifth step, China needs to build an information communication mechanism for wind energy exploration and grid planning. China should appropriately arrange early grid engineering work according to relevant departments’ wind power and transmission planning, making efforts to keep grid construction and wind power development in step with one another.

Improve National Regulations and Standards. China should build a national wind-power standard and regulation system that covers the process of research and manufacturing, planning and construction, installation, integration detection, and operation management in an effort to promote the standard development of its wind power industry.

Relevant policies that promote the wind power industry need to be improved. Administrative regulations and policies that support renewable energy law need to be developed, including price subsidies for peak and frequency regulation, and reasonable compensation standards for grid integration.

Moreover, policies need to be developed covering the on-grid price of distributed wind power, peak and off-peak prices on the supply side, and interruptible prices on the demand side to help promote wind power consumption.

Finally, studies should be undertaken to examine green-certificate systems and consumption policies that encourage renewable energy subscriptions.

Pursuing these steps will help encourage the whole of Chinese society to actively explore and consume renewable energy such as wind power.

— Zeng Ming, Xue Song, Li Ling-yun, Cheng Huan, and Zhang Ge are with the School of Economics and Management, North China Electric Power University, Beijing, China. The authors may be contacted through Li Ling-yun at lilingyunncepu@126.com.