What is the best way to construct a complete chemical-feed system for use in a power plant—piecing together equipment acquired from a hodgepodge of suppliers or creating a system with components sourced from a single manufacturer? The answer seems obvious, but decision-makers don’t always consider the ramifications of making the wrong choice.

The reliable, safe, and efficient feeding of chemicals into various critical stages of the steam-water cycle at power plants is an irreplaceable necessity for an industry that is one of the world’s most important. Among the most significant stages are pretreatment, internal treatment, and cooling treatment.

Pretreatment. The raw makeup water that passes through the power plant’s boilers that are used to create the steam that drives the turbines has to be as “perfect” as possible, or what is termed in the industry as “ultra-pure.” To get the water as pure as it can be, it passes through a series of filters or clarifiers, and demineralizers. To aid in the purification process, substances like ferric sulfate and sulfuric acid are injected in tightly controlled dosage amounts into the water. Ferric sulfate is a coagulant that causes any particles in the water to clump together for easier removal, while sulfuric acid is a strong mineral acid that helps regulate the water’s pH, or alkalinity, level.

Internal Treatment. The water in the boiler is treated for corrosion control. Phosphates are fed as buffers to resist or control pH change (Figure 1), hydrazine is fed as an oxygen scavenger to remove or help decrease oxygen, and amines are fed as steam-line treatments.

|

| 1. The phosphate injection skid shown here was installed at a combined cycle power plant in the southern U.S. Courtesy: Neptune Chemical Pump Co. |

Cooling Treatment. The cooling water is treated for corrosion control, deposition, and microbial growth. Corrosion inhibitors are fed to prevent corrosion, scale inhibitors are added to prevent scaling (a dense coating of water-soluble constituents on cooling-tower surfaces), and sodium hypochlorite is dosed to prevent biological growth.

Because the feeding of chemicals is paramount to the successful completion of these power generation operations, by extension, the chemical-feed systems that are used to propagate chemical injection must be equally important. When designed and operated properly, chemical-feed systems are effective, cost-efficient, and versatile devices that can be counted on to reliably and accurately feed the required amount of chemical into the process.

Assemble the Hardware

The challenge for operators of power generation facilities that require chemical feed is utilizing the correct chemical-feed system. Too often, however, not enough thought is put into the components used in the construction of the system. Consider an automobile purchase. Do people purchase components separately to build the vehicle or do they rely on a trusted automobile manufacturer to utilize the vehicle components that are compatible with each other, with careful thought given to how they will interact during operation? Just opening a supply catalog and selecting the cheapest alternative, or choosing a brand that sounds familiar, is not enough to ensure successful chemical-feed system operation.

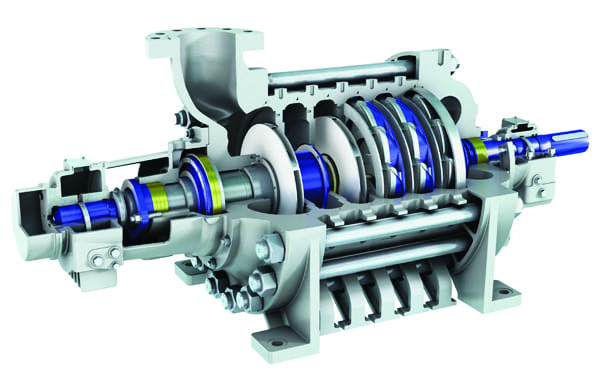

Let’s take a quick look at the particular parts that make up a complete chemical-feed system. The pumps that are used to inject or dose chemicals into the process are critical components. Diaphragm-style metering pumps have been proven to be the most-effective technology for use in chemical-feed applications, and there are generally three types of diaphragm pumps that can be used in these situations:

Hydraulic Diaphragm Metering Pumps. Hydraulically actuated diaphragm metering pumps are designed to handle the harshest chemicals. Because they are hydraulically actuated, they are able to inject chemicals at extremely high pressures. Pressures up to 3,000 or 4,000 psi are not uncommon in power plant boiler water treatment applications. They are a low-maintenance pump because most of their moving parts are submerged in a bath of hydraulic fluid, which allows them to provide 20 or more years of service.

Mechanically Actuated Motor-Driven Diaphragm Metering Pumps. Designed for low-pressure application, normally less than 250 psi, these pumps offer ease of operation and startup, but they can have higher operating costs.

Solenoid Diaphragm Metering Pumps. Solenoid actuated, or electronic, metering pumps are a viable economical option for low-flow/low-pressure chemical-dosing applications.

Another piece of equipment that is vital in the operation of a chemical-feed system is the mixer. Mixers are provided to ensure chemicals are adequately blended in the supply or holding tank prior to being injected by the metering pump. Tanks vary from a tote or intermediate bulk container (IBC) to a small day tank or a larger holding tank (Figure 2). The mixer used varies in size and shape dependent upon the tank being utilized and the chemical-mixing requirements. Mounting configurations can be a c-clamp, angle riser, flange mount, or threaded mount, while props can be fixed or folding in myriad different configurations. Also, these mixers can be direct drive, gear reduced, or variable speed, again dependent upon the application.

|

| 2. Chemical tanks come in a variety of materials, shapes, and sizes. Typically they include connections for the pump suction, drain, level gauge, chemical fill, dilution water, level switch, and relief valve return piping. Courtesy: Neptune Chemical Pump Co. |

Take a Systems Approach

While selecting the proper pump and mixer style is the most important step in creating a successful chemical-feed system, finding the right ancillary components for a system is also critical. What many design engineers don’t realize is that many metering-pump companies also develop and manufacture the components that make up a chemical-feed system. Many metering-pump manufacturers offer standard, semi-custom, and custom chemical-feed systems.

Planning the installation from the supply tank or liquid source to the injection point and determining the necessary accessories are critical. Some of the components that go into the chemical-feed system, along with their usage recommendations, follow.

Flooded suction is always preferred as it is easier to prime the pump, plus there is less chance of a starved suction condition. Limiting the suction piping to six or seven feet and making sure the suction piping is of adequate size for the metering pump is equally important. A suction strainer traps any impurities in the chemical supply while preventing any dirt or debris from getting to the metering pump’s ball checks. Isolation valves can be placed in both the suction and discharge piping of the metering pump in order to isolate it. A calibration column (drawdown cylinder) mounted in the suction line can be used to calibrate the metering pump.

Many pumps are provided with internal relief valves, but external relief valves are always recommended to be mounted in the pump discharge and piped back to the supply tank. Backpressure valves are necessary when the metering pump does not have a backpressure device or the system does not have backpressure. Check valves in the discharge piping prevent back flow. A pressure gauge can be placed in the discharge piping in order to view system pressure. A pulsation dampener provides smooth, laminar flow and prevents water hammer. Injection quills make sure the chemical is adequately dispersed. A control panel with NEMA-rated enclosure (12, 3R, 4, 4X, or 7, for example) is usually needed, and a main disconnect with hand-off-auto or on/off switches and running lights to provide local control for the system is typical.

Designed for Success

All of these recommendations and components need to be reviewed when the chemical-feed system is being designed, and who better to be able to size and select them than the designer of the system and the manufacturer of the components?

With all this in mind, design engineers should realize that no one is better qualified to assist in the selection of pumps and components, and successfully integrate equipment into a chemical-feed system than the designer and manufacturer of those pumps, mixers, and components. Because of their familiarity with the system and its components, manufacturers are also quickly able to remediate maintenance and repair needs, often solving operational problems with a single phone call.

So, what is the best way to construct a complete chemical-feed system for use in a power plant? The answer should be obvious. When building a chemical-feed system for use in power generation—the reliable operation of which is imperative to the creation of indispensable electricity for use in the national power grid—it’s best to rely on the expertise and experience of the manufacturer of the actual equipment, someone who has the knowledge to build the system correctly and the ability to quickly solve any problems that may arise. ■

—Tom O’Donnell (Tom.ODonnell@psgdover.com) is director of business development with Neptune and PSG, a Dover Company (neptune1.com).