There is a widespread movement to reduce carbon emissions around the world. One way to do so is by improving plant efficiency, but that can be easier said than done. However, self-service analytics could play a role in the process. Advanced technology can help subject matter experts spot areas for improvement faster and more effectively than was previously possible.

The discussion about climate change has been taking place for many years and is currently hotter than ever. The debate has led to global initiatives to reduce the carbon footprint, which is high on the agenda of pretty much every country’s government. The energy industry is confronted with high-impacting measures due to decarbonization programs, such as the European Union’s decarbonization target of zero by 2050. This drives the change toward renewable energy, but also asks for measures to generate carbon-neutral power.

Part of the solution is the reduction of the energy needed in power generation plants and making those plants more efficient. This can be found in two major areas: improving overall equipment effectiveness and reducing the energy in utilities required for the process of generating energy.

At a recent power conference, one expert noted that the energy sector has experienced disruptive changes over the past 20 years, but by putting climate protection first, the industry has set an unprecedented example of global leadership and has shown that change is possible in less than a decade. Decarbonization and decentralization will likely remain the focus for decades to come, yet the biggest opportunity for the industry may be to take digitalization from first-movers to full industry-wide implementation.

The external force to reduce the carbon footprint also has an overall profitability benefit. Within the power industry, energy itself is often one of the largest components of a company’s cost structure. Although energy management to reduce costs in itself is not new, it has become more important due to imposed regulations. Most companies have formalized energy management programs, and use automation and control technologies to help minimize energy costs. However, it is clear that many companies need to take their efforts to the next level by monitoring and optimizing energy use in real time, and leveraging industrial internet of things (IIoT)-generated data (data generated by sensors and devices).

For many years, process data has been captured in historians, such as OSIsoft PI and AspenTech IP-21. All this data needs to be unlocked and leveraged for continuous improvement to reduce the energy consumption of companies. Data analytics has been utilized by large companies to some extent for the biggest energy issues at sites. These time-consuming, centrally led, data-modeling projects are less suited for process-related optimization projects that require subject matter expertise. New tools put advanced analytics in the hands of subject matter experts such as process and field engineers. This allows them to handle 80% of energy-related cases that contribute to the corporate goals for reducing the carbon footprint.

Energy Management 4.0

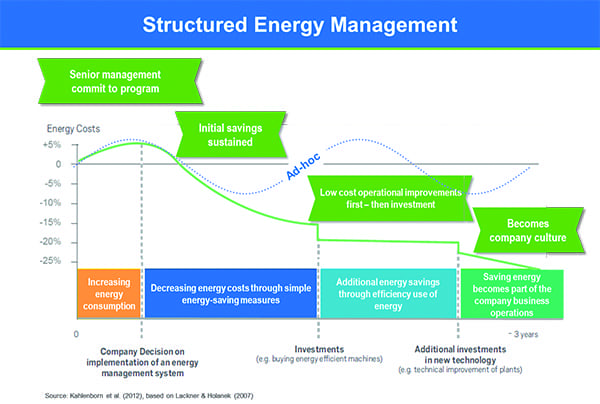

Global interest in Industry 4.0 has accelerated the digital transformation in the process manufacturing industry, including the energy sector. Many companies have engaged in technology pilots (Figure 1) to explore options for reducing costs, increasing overall equipment effectiveness, or managing regulatory compliance. One of the best ways to leverage these new innovations is to apply advanced industrial analytics to sensors-generated production data. Every piece of data provides unprecedented opportunities for improving energy efficiency.

|

|

1. It can take a few years for structured energy management (SEM) to change the culture of operations. However, once management is aligned and committed to SEM, basic energy management systems can be installed and improvements can be made to facilities management that will yield immediate benefits. Source: Department of Energy as published by Nexant Vice President of Utility Services Brian Albert, PE in “Fundamentals of Strategic Energy Management” |

In general, energy savings can be achieved in various ways, including through change in daily behavior (switching off the light), by installing more energy-efficient equipment, by maintaining equipment before it becomes inefficient, or through process optimization such as ensuring use within the best operating zones. Process and asset performance optimization are probably the biggest areas for energy savings, but they require a deeper understanding of operational process and asset data (available in the historian).

Improving Overall Equipment Effectiveness

Process engineers are responsible for the design, implementation, control, and optimization of industrial processes. They are typically involved in analyzing, upgrading, modifying, and optimizing equipment and production processes. If the production process is stagnating or under-performing, they need to figure out why, but also in the shortest time possible to avoid production losses, maintain product quality, and elude high maintenance and repair costs.

Implementing self-service industrial analytics can enable engineers to get more robust and faster insights into their operational production data. It enables them to identify new areas for performance optimization with advanced root cause analysis capabilities, monitor production to avoid abnormal situations, and even predict future evolutions of batch runs, transitions, or equipment startups in minutes. It enables the business users, such as process and asset engineers, to:

- ■ Solve previously unsolved process performance issues.

- ■ Verify hypotheses and prove them to be either true or false, so they can be addressed or ruled out for the future.

- ■ Find new ways to improve production performance, because data with captured events and early warnings provides new insights.

- ■ Use contextual information from third-party business applications to get new insights in operational performance.

- ■ Use actionable dashboards to monitor operational performance in real-time (Figure 2).

|

|

2. Analytics-driven production cockpit, helping engineers to monitor and continuously improve overall equipment effectiveness. Courtesy: TrendMiner |

By working on all these situations, the result is a higher overall equipment efficiency, where the asset performance is optimized within its operational context, leading to waste reduction, higher and cleaner uptime, and reduction of the carbon footprint of the plant.

Analyze, Monitor, and Predict WAGES Consumption

The major process-related energy consumers can be easily remembered using the acronym WAGES, which stands for hot water, air, gas, electricity, and steam. WAGES can be directly or indirectly analyzed through all the sensor data. The data can be analyzed descriptively to see what has happened, which provides the best understanding if a long period of performance can be assessed. Sometimes, certain issues happen only a couple of times per year, but can have a big impact on energy consumption, for example, a trip causing a shutdown. Discovery analytics helps to understand what has happened and through diagnostic analytics the organization can start monitoring the performance of the site.

Because asset performance is contextualized by the process it functions in, best operating zones or best performance windows need to be subtracted from actual process behavior rather than theoretical data. Historical data fingerprints can be created to monitor good and bad behavior, optionally with an energy consumption focus. Next, live operational performance data can be used for predictive analytics; for example, performance downstream might be caused by behavior an hour or more upstream.

Practical Use Cases

Advanced analytics have been applied to analyze, monitor, and predict process and asset performance for many energy management-related use cases. Two instances are described below.

Increased Efficiency of a Power Generation Plant. A typical combined cycle gas power plant for producing electricity is equipped with two turbines that power a generator. The primary turbine is powered by hot air, which is generated by burning the gas. The secondary turbine is powered by steam that is generated by heating up water with the exhaust gases coming from the primary turbine.

Over time, the performance of a unit at one particular power station began to worsen, leading to capacity loss and lost revenue. The loss was gradual, so the change went unnoticed at first. A decrease in performance is usually a gradual phenomenon that only comes to surface after a long period of time. With the self-service advanced analytics tool, the engineers could clearly visualize operations over time. Using a value-based search, the decline in performance was quickly confirmed and quantified. This formed the foundation for the rest of the troubleshooting analysis.

Due to external factors, such as unplanned downtime and market-driven load reductions, the team needed to dig deeper to measure the actual performance of the unit. To do this, researchers compared the periods of good performance with the periods of bad performance.

The engineers found that the gas fuel flow, the compressor discharge temperature, and the inlet guide vanes reference angle differed consistently for both groups of layers. With the self-service analytics tool it could be proven that the root cause of the problem was the non-calibrated inlet guide vanes, which impeded air and fuel supply, and ultimately power generation in the gas turbine. In only four hours, the engineers efficiently identified and resolved the 2-MW capacity loss without the need of data scientists.

Control Energy Consumption within the Cooling Water Network. A number of reactors were consuming cooling capacity from the utility network for cooling water. Sufficient cooling capacity is critical for these reactors, as thermal runaway could occur when the available capacity is insufficient.

To avoid this undesirable situation, advanced analytics were set up to monitor the cooling capacity in real time. Early warnings were created and designed to trigger only on actual problem situations, avoiding false positive alarms that could be triggered by measurement noise or spikes in the data. Now, upon a warning, there is ample time for the process engineer and operators to re-balance the reactors and deprioritize other equipment, so that the critical components can consume the maximum cooling capacity while keeping overall energy consumption within target boundaries.

Energy management is not new; many companies have a structured energy management program in place. However, new self-service analytics tools allow subject matter experts to analyze, monitor, and predict process and asset performance more quickly and accurately, which can result in a huge contribution to meet the organizational carbon-footprint goals. This is especially important after the low-hanging fruit for energy savings have been picked and more knowledge is needed to improve operational performance. Companies benefit by improving overall profitability and increasing safety. ■

—Edwin van Dijk is vice president of marketing with TrendMiner, a company that develops advanced analytics solutions for the process industry.