Amanda Neuenfeldt is the energy management system (EMS) modeling lead engineer at Actalent, a global company specializing in engineering and sciences services, along with talent solutions. Neuenfeldt works with emerging grid technologies related to artificial intelligence (AI), machine learning (ML), and cybersecurity. She has studied the application of a predictive machine learning algorithm, coupled with an artificial intelligence optimization algorithm, to reduce grid generation deviations while automating the control functions to reduce control latency and increase reliability.

Neuenfeldt recently provided POWER with insight about her company’s work, including its use of data and device models to support grid reliability and resiliency.

POWER: What are some enhancements that can be made to an electricity transmission and distribution system and/or a power plant (thermal or renewable) to improve its reliability?

Neuenfeldt: A major improvement we’re working on as far as system reliability is aligning the data across different systems. Planning, protection and controls, energy management systems (EMS), and supervisory control and data acquisition (SCADA) systems often operate independently, causing misalignment that leads to delays and extra work. To address this, we’re aligning models like General Electric’s and other operational device models (ODMs) as well as collaborating with regional transmission organizations (RTOs) to ensure consistency. Over the past year, we’ve completed around 20 sub-projects focused on cleaning and aligning data—reviewing SCADA points, values, ratings, and impedances. By ensuring all systems share a reliable, synchronized dataset, we’re building a foundation for more accurate and dependable operations moving forward.

POWER: What are some of the maintenance programs that can be implemented to make a power plant and/or a power grid more reliable? How can this maintenance be automated?

Neuenfeldt: We’re working with data standards like CIM (Common Information Model) 61 970, 301 for normalization and alignment, and the emerging 61 850 standard for smart grids. The goal is to gather comprehensive data through widespread sensor networks, enabling more reliable predictions and better preparedness for capacity expansion. Given the complexity and scale of this data, machine learning and AI are essential to accurately forecast and automate maintenance, which is why we need to have all the data aligned. AI is great, but if you’re feeding data that is misaligned or just untrue, your predictive model isn’t going to make very accurate predictions.

POWER: How important is redundancy as part of power plant/power grid operations?

Neuenfeldt: The most crucial point of redundancy is avoiding power outages. I live in Texas and was one of many people who did not have water or electricity for a week during winter storm Uri because we didn’t have that redundancy. And tragically, people died because it was too cold and when the power went down heating systems stopped working. So that hit hard, and it is why we need to make sure these systems are redundant. As we anticipate issues with climate change and the increase in energy demands that it brings, we need to make sure that we’ve got the capacity to meet those demands, and the interconnections to redirect energy in an emergency, while remaining cost effective. A reasonable balance of redundancy will be obtained with accurate, timely, and reliable predictive data that is then optimized with smart calculation systems using artificial intelligence.

POWER: How can operations be standardized to improve reliability?

Neuenfeldt: Common Information Model connectivity and integration. One immediate benefit of CIM is the synchronization and normalization of data from various systems resulting in the elimination of false entries in systems. It all comes back to ensuring the data is aligned and “speaking the same language”, that’s the north star of reliability at this point.

POWER: What are some of the specific components/equipment that can be used to enhance reliability?

Neuenfeldt: Increased accuracy and verification in data and models. It all comes back to data reliability. The only truly viable way to obtain this is the centralization of data, or interfaces and integrations that result in synchronized data between systems. These systems all work in concert with one another, but all speak different languages. Once we can get the systems to all speak the same language in terms of data, that will be the biggest component in enhancing reliability.

POWER: How can model predictive control be used to enhance reliability?

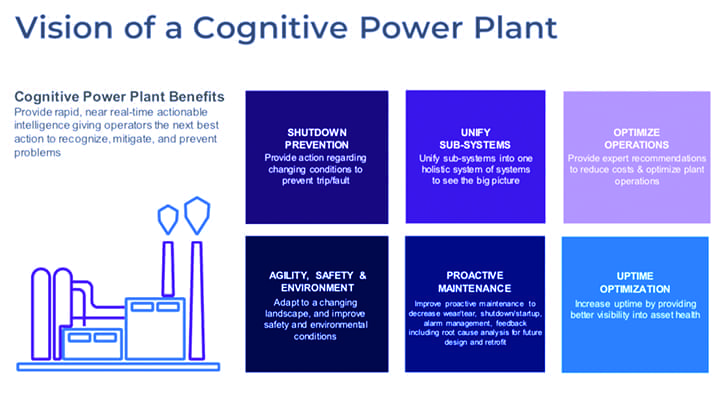

Neuenfeldt: Introducing a predictive model can minimize delays, result in a reduction in equipment damage and outages, increase efficiency and reduce costs. It also leads to better cross utilization of systems and equipment to create redundancies; predictive grid state values can be created via CIM connectivity and integration.

POWER: How can a program be implemented to enable proactive replacement/restoration of older equipment (both software and hardware) in power plant and power grid systems?

Neuenfeldt: Using machine learning and predictive tools to calculate the mean time between failure values for specific individual pieces of equipment will be huge. This, combined with optimized maintenance programs using AI and equipment replacement scheduling will enable proactive replacement without disruption to the system.

With aging grid systems, increased demand, weather dynamics, and various green initiatives, reliability will be dependent on smart-grid components utilizing artificial intelligence, real-time data acquisition, centralized data availability, and optimization of systems and components at all levels. The current strides in the initial implementation of CIM-based systems and components will open the door to the smart components and systems that will provide the essential needs required to provide the reliability demanded by consumers and regulatory agencies.

POWER: What are some of the power outage management systems (OMS software or others) used by your company, or that you are familiar with?

Neuenfeldt: While I am not directly working with these systems, I am supporting them through work with one of our clients, a large utility company that is working on integrating multiple systems and databases together. Basically, we’re taking all these misaligned systems and streamlining them into one model. The CIM model is a centralized data repository, and every RTO that exists in North America is going to be attached to this CIM because for AI and machine learning to effectively work, you’ve got to have data from everywhere. When we’re looking at machine learning and AI on the grid for automation, you need every RTO involved. You need the sensors to collect the information, and you need the central data repository to store that information.

POWER: How can software upgrades help power plant operators, and power grid managers, better manage power outages?

Neuenfeldt: Our current project is an implementation of the CIM. When this is complete it will serve as the foundation for smart components to automate and aid power grid managers in handling power outages as well as increased efficiency, reliability, and profitability.

POWER: How important is being able to have real-time information to anticipate outages caused by extreme weather or high demand for electricity?

Neuenfeldt: Reliable, stable, and accurate forecasting is crucial since our current infrastructure and procedures are not capable of meeting what we predict we’ll need in the future. There has been an increase in grid complexity and energy demands, but a reduction in overall grid inertia. Real-time information will also be essential for the implementation of smart-grid components as well as machine learning and artificial intelligence tools. Once the integration project my client is working on goes live, and as they are successful in the data normalization, the flood gates are going to open and you’re going to see more projects for data integration and more RTOS getting on board.

POWER: How does your company use (or what is your familiarity with) data sources to determine the location of an outage and the number of affected customers?

Neuenfeldt: I am not working in an area directly dealing with real-time reporting of outages, however the CIM implantation with this integration project is the bedrock of the collection and distribution of that data for use in real-time response. This project is a centralized data repository, and we’re more concerned with aligning the data so that in the future these data sources are easier to use and more reliable.

The success of projects that aim to provide centralized and uniform data for multiple systems will be the foundation spurring the industry to implement the CIM and pave the way for many new and improved outage management and response tools, systems, and techniques.

—Darrell Proctor is a senior editor for POWER.