Geothermal power offers a stable, continuous source of renewable energy that could help power millions of homes while reducing dependence on fossil fuels. As governments worldwide pursue sustainability goals, selecting the right technologies—particularly synchronous generators and induction motors—is crucial for maximizing the efficiency and reliability of geothermal power plants.

As the world moves away from fossil fuels, renewable energy sources like geothermal power are becoming increasingly critical in reaching global sustainability and net-zero goals. Unlike wind and solar energy, which depend on weather conditions, geothermal power provides a stable and continuous energy source. It is a reliable option for governments seeking to reduce their dependence on fossil fuels as it offers low-carbon electricity generation.

In the U.S. alone, it is thought that geothermal energy could capture enough natural heat to power more than 65 million homes. However, while geothermal energy is a clean, sustainable power source, capturing the Earth’s heat and efficiently converting it into electricity remains a complex challenge. It is essential that geothermal plant operators select the right technology to ensure optimal performance, long-term reliability, and cost-effective operations.

A mix of complex technology is required for this process—while attention often focuses on the turbines that directly create the electricity, there are many other vital components without which the process couldn’t happen. Chief among them are synchronous generators, which are connected to the turbines to generate electric power, and induction motors that are also integral to supporting functions like cooling and managing heat rejection. Choosing the right generators and motors can significantly improve geothermal plant efficiency, reduce maintenance costs, and contribute to overall system reliability.

The Role of Synchronous Generators and Induction Motors

Generating electricity from geothermal energy is a complicated process that relies on underground reservoirs of water heated by the Earth’s crust. The steam created in the reservoirs is drawn to the surface (Figure 1) and extracted through wells, often drilled one to three kilometers deep. Once at the surface, the steam is directed toward turbines, which spin and drive generators. These generators then convert the mechanical energy into electricity. After passing through the turbine, the steam is then cooled and condensed back into water, after which it is re-injected into the Earth to maintain the reservoir.

|

|

1. A geothermal power station on Reykjanes peninsula in Iceland is shown here. Iceland generates approximately 25% to 30% of its electricity from geothermal energy sources. Courtesy: ABB / Adobe Stock |

While turbines are the most visible part of the system, they cannot function without supporting technology like synchronous generators and induction motors. These components ensure that the entire system runs smoothly, particularly in managing power generation, cooling, and heat rejection, three of the most critical processes in geothermal power generation, which help run the process efficiently.

One of the biggest operational costs in geothermal plants is heat rejection, which can account for up to one-third of total expenses. After the steam is extracted from underground water reservoirs and used to drive the turbines, the excess heat must be dissipated to maintain efficiency. Cooling tower fans, powered by induction motors, play a key role in this process, ensuring that hot fluids are properly cooled before being reinjected into the system or disposed of safely. Induction motors with variable-speed drives also play a significant role by keeping cooling systems running at their best efficiency point, regardless of load variations. This minimizes wasted energy and enhances overall plant performance. Additionally, induction motors are used in water pumping systems to circulate cooled water, preventing thermal buildup and maintaining optimal operating temperatures.

Reliable Designs for Optimal Performance

Geothermal plants expose motors and generators to extreme heat, corrosive chemicals, and fluctuating power demands, which can put them under significant strain. As a result, it is important that geothermal plant technology is designed to withstand harsh environmental conditions and to operate reliably.

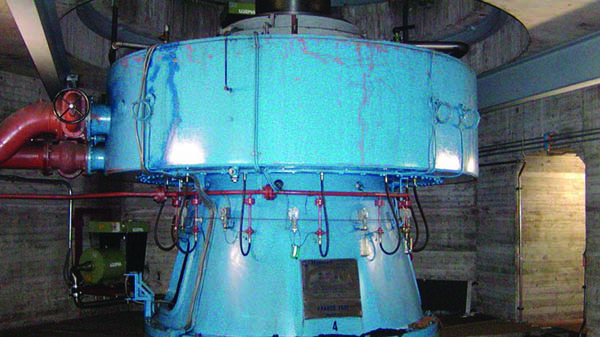

Solutions that utilize advanced materials, corrosion-resistant coatings, and intelligent drive systems are specifically designed to withstand these challenges. Heat resistant materials allow synchronous generators (Figure 2) and induction motors to function continuously in high-temperature environments without degradation, while corrosion-resistant coatings protect from the gradual damage caused by minerals and gases in geothermal steam.

|

|

2. Synchronous generators (left) and induction motors (right) are fundamental components in power generation facilities. Synchronous generators convert the mechanical energy from turbines into electrical power, while induction motors drive essential support systems like cooling towers, water pumps, and fans. Courtesy: ABB |

The robust designs of synchronous generators and induction motors help mitigate common operational risks and are essential to maintain consistent power generation, while also helping to extend their lifespan and reduce long-term maintenance costs. Additionally, drive systems allow for real-time monitoring, enabling predictive maintenance that minimizes unplanned downtime and allows for early discovery of possible issues.

Another important factor to consider when choosing the technology is how to optimize energy use. Like other power generation methods, geothermal plants experience fluctuating loads and energy demands depending on environmental conditions and grid requirements. Cooling needs, for example, vary based on ambient temperatures and plant output.

Induction motors (Figure 3), equipped with variable-frequency drives (VFDs), allow for precise speed control, enabling operators to adjust motor speeds in real-time and adapt to fluctuating cooling demands. During cooler periods, motors can slow down to conserve energy, while during peak heat loads, they can increase speed to ensure adequate cooling. This flexibility significantly improves energy efficiency and reduces operational costs. The ability to adjust motor speeds dynamically, rather than running them at a constant rate, also minimizes wear and tear, further extending the lifespan of critical equipment.

Cutting-Edge Technology in Action

This advanced technology has been successfully implemented in geothermal power plants around the world. For instance, ABB has supported Kaishan Group in advancing geothermal power production in Indonesia. Based in China, Kaishan is a diversified engineering company known for its innovative modular geothermal power stations. The company constructed two geothermal power plants in Indonesia: the Sorik Marapi project in Sumatra, with a capacity of 240 MW, and the Sokoria project in East Nusa, with a capacity of 30 MW.

To enhance the efficiency of these plants, ABB supplied two synchronous steam turbine generators, each rated at 12 MVA. The specification required an efficiency level of 97%, which was surpassed in type testing, where the actual efficiency level was shown to be 98.37%. This performance has contributed to reducing annual carbon dioxide emissions by approximately 1,310 tonnes in the plants—the equivalent of the emissions generated by supplying electricity to 255 homes for a year.

Supporting the Energy Transition

The international community’s transition away from fossil fuels requires energy solutions that are not only environmentally sustainable, but also cost-effective and reliable. Geothermal power, with its continuous energy output and minimal environmental impact, has the potential to become a cornerstone of the clean energy future.

However, to maximize its potential, operators must invest in the right technology to optimize efficiency and ensure long-term reliability, helping to drive the global shift toward cleaner, more sustainable energy sources. High-efficiency synchronous generators, durable induction motors, and intelligent variable drive systems provide plant operators with the tools needed to enhance system performance while reducing costs. By doing so, operators can ensure a more sustainable future for geothermal energy production and support governments in achieving broader energy transition and net zero goals.

As the world accelerates its transition to renewable energy, geothermal power stands out as a dependable and sustainable solution. With the right investments, geothermal energy can play a leading role in the world’s transition to a carbon-free future.

—Luca Rizzo is global industry manager at ABB Large Motors and Generators.