In order to burn abundant supplies of coal globally while minimizing carbon dioxide emissions, cheaper methods of capturing, using, and storing greenhouse gas emissions from power plants are needed. A new federal agency is on the leading edge of identifying and supporting promising technologies.

The technology options available today for capturing carbon dioxide (CO2) from fossil-fueled power plants are limited and involve daunting energy penalties. They’re also expensive, adding up to 80% to the cost of power generation. Current options for using captured CO2 are mostly limited to enhanced oil recovery, which means this use of the captured, compressed, and transported greenhouse gas is limited geographically and practically. Other storage options are in their infancy and look expensive, if not cost-prohibitive. So where does that leave the power industry as it looks to a future that (especially given President Obama’s recently announced Climate Action Plan) is sure to include some sort of imperative to capture carbon emissions?

A few carbon capture and sequestration (CCS) research and pilot projects are under way around the world, but most have been on-again/off-again ventures, mostly because of uncertain regulatory, legal, and financing environments. But that doesn’t mean the issue is going away. In the U.S., the Department of Energy’s (DOE’s) newest agency takes the challenge seriously and is encouraging innovative research and development (R&D) to solve the puzzle of how to keep CO2 from energy-production activities out of Earth’s atmosphere.

At the 4th Annual Energy Innovation Summit (EIS) in February, more than 20 Technology Showcase displays focused on carbon capture, utilization, and storage (CCUS). The EIS is sponsored by the DOE’s Advanced Research Projects Agency–Energy (ARPA-E), the four-year-old sibling of the Defense Department’s DARPA. As of this spring, the ARPA-E website listed a total of 15 projects that were part of the agency’s Innovative Materials and Processes for Advanced Carbon Capture Technologies (IMPACCT) program.

ARPA-E focuses on modest-size, short-term grants for projects that are at too early a stage to attract private, venture capital. And although the funding provided by ARPA-E may be its most visible role, at least as important are the partnerships it arranges for the projects it funds. By bringing a variety of researchers, national laboratory scientists, and corporate partners together, ARPA-E connects individuals and groups that might not have had access to each other or who wouldn’t have thought they could help solve each other’s problems. Such strategic partnerships are important not just for solving technical problems but also for making the transition to a stage where private investors become interested. (For more on the agency, search for “ARPA-E Plays Matchmaker for Innovative Energy Research Projects” at powermag.com.)

Make an IMPACCT

IMPACCT’s goal is to “develop technologies for existing coal-fired power plants that will lower the cost of carbon capture.” It is geared toward minimizing CO2 capture costs “by developing materials and processes that have never before been considered for this application.” As the program description notes, “Retrofitting coal-fired power plants to capture the CO2 they produce would enable greenhouse gas reductions without forcing these plants to close, shifting away from the inexpensive and abundant U.S. coal supply.”

Note that this approach is in contrast to the original vision of the public-private FutureGen project, which was to be a new-build coal-fired plant with near-zero carbon emissions. FutureGen 2.0 aims to use oxy-combustion technology on an upgraded plant (see “Oxy-Combustion: A Promising Technology for Coal-Fired Plants” in the January 2011 issue).

ARPA-E acknowledges that “Coal will continue to provide most of the electricity in the U.S. for the foreseeable future. Enabling the continued use of abundant, domestic resources will promote a safe, reliable, and consistent electric grid as the renewable energy industry develops.”

The IMPACCT projects are not the only research efforts out there, but they do represent a carefully curated portfolio of U.S.-based R&D programs and, as such, provide a glimpse at what the future may hold. Fifteen IMPACCT projects have been awarded a total of $39,929,110. Other projects related to CCUS have been funded through other funding opportunities, including “open” (non-program-specific) funding opportunities. ARPA-E has also funded carbon capture technology projects through 2009 and 2012 open funding opportunities with a combined award total of approximately $19 million.

New Ways Forward

ARPA-E’s general approach is to carefully select the most promising candidates from a variety of proposed technology approaches for funding, provide access to strategic partners who can more quickly advance the research, and limit the dollar amount and timeframe for the award to motivate fast learning—and success or failure.

When asked which CCUS projects are furthest along the path toward potential commercialization, the agency noted that several IMPACCT projects are showing signs of success:

- Texas A&M University created a spinout company, Framergy, to help commercialize its technology.

- Ohio State University has begun Phase 3, Construction and Operation, of a pilot-scale demonstration of Syngas Chemical Looping at the National Carbon Capture Center in Wilsonville, Ala.

- ATK and ACENT Laboratories have developed ICES (Inertial CO2 Extraction System) to centrifugally separate solid CO2.

Solvent-Based Capture

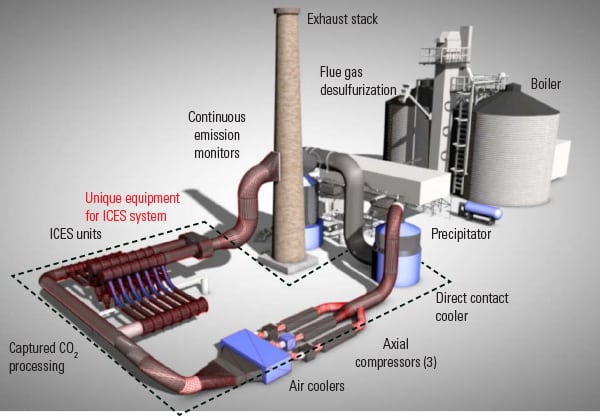

RTI International is developing a solvent and process that it says could significantly reduce the temperature associated with regenerating solvent and CO2 captured from coal plant exhaust (Figure 1). Its process may be most similar to familiar approaches.

|

| 1. Designing a superior solvent process. The approach taken by the RTI International team, shown here, is to reduce the temperature required for regenerating solvent and CO2 captured from coal plant exhaust. Source: RTI |

However, the project team makes the distinction that “Traditional CO2 removal processes using water-based solvents require [a] significant amount of steam from power plants in order to regenerate the solvent so it can be reused after each reaction. RTI’s solvents can be better at absorbing CO2 than many water-based solvents, and are regenerated at lower temperatures using less steam. Thus, industrial heat that is normally too cool to re-use can be deployed for regeneration, rather than using high-value steam.” The result is a lower cost penalty for CO2 capture.

Phase-Changer

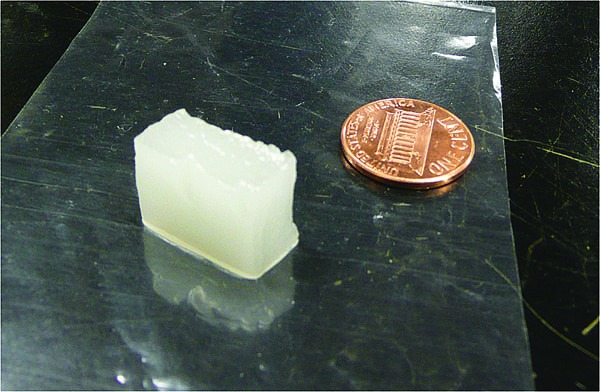

GE and the University of Pittsburgh are developing a CO2 capture process in which a liquid absorbent, upon contact with CO2, changes into a solid phase. “Once in solid form, the material can be separated and the CO2 can be released for storage by heating. Upon heating, the absorbent returns to its liquid form, where it can be reused to capture more CO2.”

Researchers say the approach is more efficient than other solvent-based processes “because it avoids the heating of extraneous solvents such as water. This ultimately leads to a lower cost of CO2 capture and will lower the additional cost to produce electricity for coal-fired power plants that retrofit their facilities to include this technology.”

Gel Capture

Several IMPACCT projects are sidestepping the familiar carbon storage paradigm that involves compression, transportation via pipeline, and underground injection. Instead, they are exploring options for transforming CO2 into a state that can be more easily stored or, better, reused—sometimes onsite, as fuel. When taking this route, cost is not necessarily a deal-breaker, Dr. Richard Noble assured me. Noble is a professor in the Chemical and Biological Engineering Department at the University of Colorado at Boulder and co-director of its NSF Industry/University Cooperative Research Center for Membrane Applied Science and Technology.

The project Noble leads at CU-Boulder has Los Alamos National Laboratory and the Electric Power Research Institute as partners in developing a membrane made of a gelled ionic liquid to capture CO2 from flue gases (Figure 2).

|

| 2. Smart gel. A gel membrane being developed at the University of Colorado at Boulder promises to capture and hold carbon dioxide from flue gas. Courtesy: CU-Boulder |

The project site explains that “The membranes are created by spraying the gelled ionic liquids in thin layers onto porous support structures using a specialized coating technique. The new membrane is highly efficient at pulling CO2 out of coal-derived flue gas exhaust while restricting the flow of other materials through it. The design involves few chemicals or moving parts and is more mechanically stable than current technologies. The team is now working to further optimize the gelled materials for CO2 separation and create a membrane layer that is less than 1 micrometer thick.”

According to ARPA-E, the payoff is that “If successful, CU-Boulder’s design would create a membrane that captures CO2 at a cost of less than $20 per ton, a level significantly lower than current-generation technologies.” (Nevertheless, that could still mean a significant increase in the price of electricity, as the typical conventional coal plant emits about 1 ton of CO2 per MWh, so the incremental cost of the technology is equivalent to $20/MWh. For reference, the U.S. Energy Information Administration found that the average on-peak cost of wholesale electricity in 2012 ranged from $22.56/MWh in the Northwest to $46.57/MWh in the New York ISO.)

The process results in an enriched gas after capture, Noble told me in February. Other researchers are working on ways to convert that enriched CO2 to a fuel that can then be recycled right at a power plant, which could result in a carbon-neutral facility—and potentially offset the carbon capture cost. Now in its third year, the project is working with 3M to do small-scale pilot testing.

Electrical Separation

In contrast with current heat-based amine systems for CO2 capture, Massachusetts Institute of Technology researchers are working with Siemens Corp. on electrically driven systems that promise to be more energy efficient.

The process would separate CO2 from the exhaust of coal-fired power plants “by using electrical energy to chemically activate and deactivate sorbents, or materials that absorb gases. The team found that certain sorbents bond to CO2 when they are activated by electrical energy and then transported through a specialized separator that deactivates the molecule and releases it for storage. This method directly uses the electricity from the power plant, which is a more efficient but more expensive form of energy than heat, though the ease and simplicity of integrating it into existing coal-fired power plants reduces the overall cost of the technology.”

Carbon Mineralization

Columbia University is developing a way to turn flue gas CO2 into a solid that can be “easily and safely transported, stored above ground, or integrated into value-added products (e.g. paper filler, plastic filler, construction materials, etc.).” The researcher I spoke with at the EIS noted that these uses would be limited to perhaps 3% of the output so as not to flood the market; the rest would go to underground storage.

Carbon mineralization already occurs in nature, when CO2 reacts with various minerals over long periods of time, resulting in a solid carbonate. However, “The use of carbon mineralization as a CO2 capture and storage method is limited by the speeds at which these minerals can be dissolved and CO2 can be hydrated. To facilitate this, Columbia University is using a unique process and a combination of chemical catalysts which increase the mineral dissolution rate, and the enzymatic catalyst carbonic anhydrase which speeds up the hydration of CO2.”

If the Columbia project is successful, it would offer a “simple way” to limit CO2 emissions, and the “easily visible evidence of stored carbon eliminates the need for long-term monitoring of stored CO2.” No worries about invisible seepage of compressed gas.

Crystalline Compounds

You might think of Lawrence Berkeley National Laboratory’s (LBNL’s) project as a more benign version of the Start Trek crystalline entity (which grabbed on to anything and everything organic to turn it into power). LBNL is trying to identify the best metal organic frameworks for use in capturing CO2.

Here’s how LBNL describes its approach: “Metal organic frameworks are porous, crystalline compounds that, based on their chemical structure, vary considerably in terms of their capacity to grab hold of passing CO2 molecules and their ability to withstand the harsh conditions found in the gas exhaust of coal-fired power plants. Owing primarily to their high tunability, metal organic frameworks can have an incredibly wide range of different chemical and physical properties, so identifying the best to use for CO2 capture and storage can be a difficult task. LBNL uses high-throughput instrumentation to analyze nearly 100 materials at a time, screening them for the characteristics that optimize their ability to selectively adsorb CO2 from coal exhaust.”

Carbon Sponge

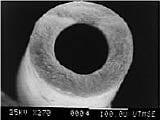

Oak Ridge National Laboratory (ORNL) is working with Georgia Tech to develop a new technology that will “act like a sponge, integrating a new, alcohol-based ionic liquid into hollow fibers [Figure 3] to capture CO2 from the exhaust produced by coal-fired power plants.”

|

| 3. Carbon sponge. When you spill something at home, odds are you use an absorbent towel or sponge to clean up the mess. Researchers at Georgia Tech and ORNL are working on a carbon clean-up technique that absorbs carbon dioxide in an analogous way. Source: ORNL |

Here’s the rub: “Ionic liquids, or salts that exist in liquid form, are promising materials for carbon capture and storage, but their tendency to thicken when combined with CO2 limits their efficiency and poses a challenge for their development as a cost-effective alternative to current-generation solutions. Adding alcohol to the mix limits this tendency to thicken in the presence of CO2 but can also make the liquid more likely to evaporate, which would add significantly to the cost of CO2 capture. To solve this problem, ORNL is developing new classes of ionic liquids with high capacity for absorbing CO2.”

From Aerospace to Power Generation

University and national lab researchers aren’t the only ones involved in visionary CCUS research. A video that ran during one of the EIS general sessions featured work by Alliant Techsystems (ATK) and ACENT Laboratories that involves applying an aerospace technology to carbon capture to develop a solution that can be retrofitted to coal plants. It entails compressing flue gas by accelerating it supersonically using wind-tunnel technologies to drop the temperature and freeze out the CO2 as dry ice, a “condensed solid,” for collection and capture.

The project site explains that “ATK’s design incorporates a special nozzle that converges and diverges to expand flue gas, thereby cooling it off and turning the CO2 into solid particles which are removed from the system by a cyclonic separator. This technology is mechanically simple, contains no moving parts and generates no chemical waste, making it inexpensive to construct and operate, readily scalable, and easily integrated into existing facilities. The increase in the cost to coal-fired power plants associated with introduction of this system would be 50% less than current technologies.”

Who’s in the Lead?

When speaking at the EIS about the agency’s CCUS focus, IMPACCT Program Director Dr. Karma Sawyer noted that “we’re not ready” to capture carbon at scale; there’s a “massive technical gap” where CCUS is concerned, which is why ARPA-E is looking at it. The current amine-based technologies increase the cost of electricity by 60% to 80%.

When asked by POWER this spring if she expected one technical approach to become the clear market leader or if a handful of different approaches were likely to become viable, Sawyer responded: “ARPA-E always funds multiple approaches towards a program goal to hopefully catalyze breakthroughs in multiple energy technologies; IMPACCT is no different.”

She added, “Right now, I am particularly excited about some of our technologies that have the potential to drastically reduce (>50%) the capital cost of a large-scale project and technologies that utilize changes in entropy to substantially reduce the parasitic power load for the capture process.”

When asked about R&D competition from other countries, Sawyer noted, “ARPA-E has sparked a lot of interested both domestically and abroad, as you can see from the ARPA-E Summit with over 20 countries engaged at the conference. We’re also heavily engaged with the carbon capture community as a whole, to help foster connections, partnerships, and gain a better understanding of CCUS technology R&D. That being said, right now, my focus is to advance IMPACCT projects here in the U.S. to help our awardees achieve their technical and tech-to-market milestones and strive to develop technologies that will reduce CO2 emissions from coal-fired power plants.”

— Gail Reitenbach, PhD is POWER’s managing editor.