Billerica, MA: Cabot Corporation recently introduced EnovaTM at the European Coatings Show in Nuremberg, Germany. EnovaTM aerogel is a revolutionary new high performance thermal additive designed specifically for insulation coatings. Cabot researchers have found that applying a 1mm coating containing EnovaTM aerogel to a 200°C metal surface meets US and European testing protocols for safe touch temperature, preventing the first-degree burns one would normally expect within five seconds of skin contact. This not only protects employees, but also helps keep the pipe contents at desired temperature. Coatings containing EnovaTM aerogel can also be used to insulate cold surfaces helping to eliminate freezer burns and to reduce the power requirements needed to keep contents cold.

EnovaTM aerogel is designed for application to surfaces that are not already insulated but ideally should be. This includes hard to reach and expansive areas of exposed metal where traditional insulation methods cannot be used due to limited access, size or shape. EnovaTM aerogel can be added during formulation or on site and does not adversely affect the viscosity of the coating enabling it to be applied easily to a surface.

Most industrial applications can benefit from this new insulating additive, as well as any installation or piece of equipment that has bare metal that requires insulation. Chemical plants to reactors, HVAC equipment to catering appliances, even shipping containers, can all be protected with a thin insulating coating that is also inherently hydrophobic and helps protect the contents from seawater.

‘EnovaTM aerogel creates a paradigm shift in how the industry thinks about insulation and coatings – two products which were once mutually exclusive’, said James Pidhurney, Global Segment Manager with Cabot Corporation. ‘It enables a new class of coatings to be produced that combines the performance of traditional insulation with the flexibility of a coating in a single product.’

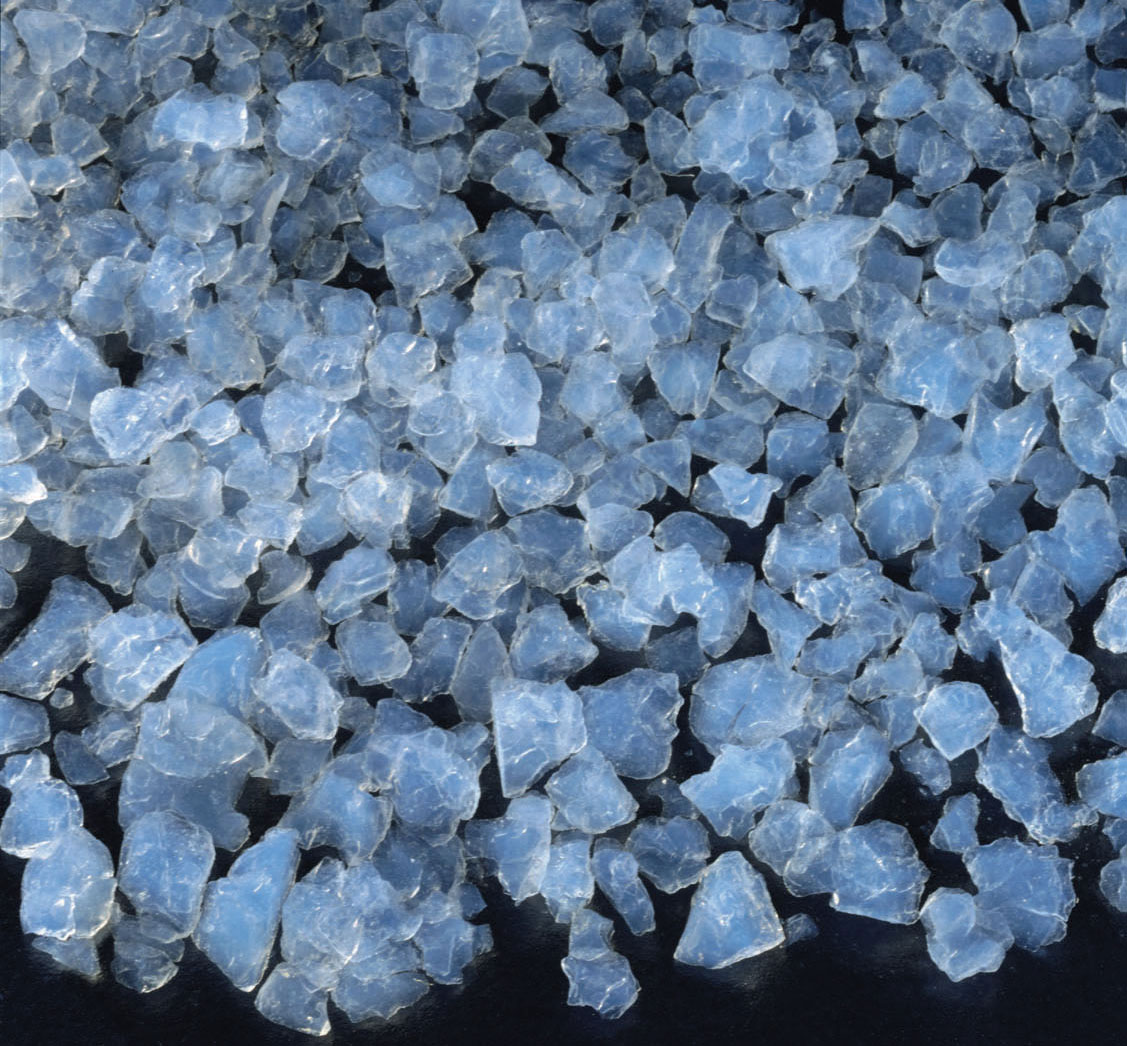

Cabot’s EnovaTM product line is made up of aerogel, the world’s best insulating solid particle. Each particle consists of more than 90 per cent air trapped within a network of amorphous silica making it twice as insulating as still air. The exceptionally low thermal conductivity of EnovaTM aerogel – 12 mW/mK — is far superior to traditional insulation such as polyurethane foam (typically 30 mW/mK) and additives such as glass or ceramic microspheres. When used in water-borne formulations, the resultant coating can achieve a thermal conductivity, which is seven to ten times more insulating than standard paint.

Cabot’s EnovaTM is also a Silver Cradle to Cradle Certifiedsm material. This stringent independent certification process by McDonough Braungart Design Chemistry (MBDC) examines a product’s manufacturing characteristics together with its ecological impact and recyclability. The aim is to eliminate waste entirely and to create a healthy and sustainable society. As such, EnovaTM aerogel is a natural fit for eco-friendly water-based coatings.

For more information about Enova aerogel please visit www.cabotaerogel.com