TREO 2000 uses the latest AES fiber technology to enhance safety and thermal performance

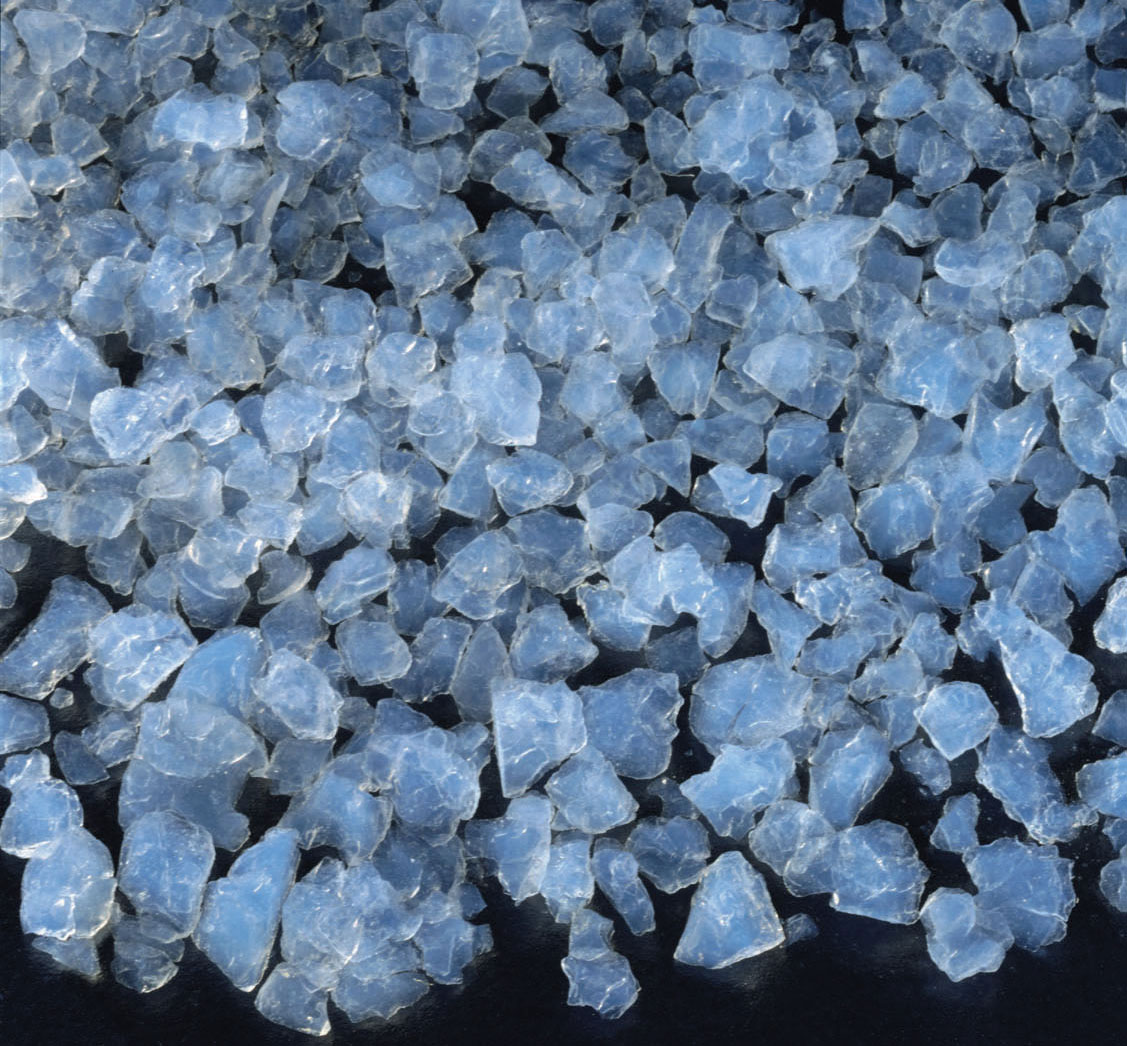

INDEPENDENCE, VA, October 6, 2020 – McAllister Mills, a global leader in the manufacture of precision-engineered thermal fabrics and products, has introduced TREO® 2000, the company’s newest bio-soluble high-temperature blanket that uses the latest in AES (alkaline earth silica) fiber technology. TREO 2000 high temperature blankets can achieve continue use temperatures of 2000°F (1100°C), and the unique fiber chemistry is non-respirable and safer to use in application. TREO 2000 is available from ¼” through 2” (6mm – 50mm) thickness and 48” (1.22 meters) width. Standard product density is 8 pounds (128kg).

TREO 2000 high-temperature blanket exhibits low shrinkage at use temperature, low thermal conductivity, and is easy to fabricate, making it an effective choice across a wide range of applications in a number of industries. McAllister Mills can customize the thickness and density of the end product, allowing for even greater flexibility across multiple types of applications.

“The ability to customize the thickness and density of a thermal blanket is extremely important to our customers, and TREO 2000 offers them that ability in a product that can achieve continuous use temperatures of 2000°F,” said Alec McAllister, president of McAllister Mills. “The unique fiber chemistry used also makes the TREO 2000 thermal blanket safer compared to blankets made with ceramic or asbestos. Increased product flexibility combined with increased safety makes TREO 2000 thermal blankets a win-win proposition.”

The bio-soluble fibers in TREO 2000 are asbestos and ceramic-free and are less bio-persistent, so they are eliminated more quickly by the body while still maintaining excellent thermal insulation and fire protection qualities.

TREO 2000 provides effective solutions to a variety of thermal management challenges and is unaffected by most chemicals except strong alkalis, phosphoric acid, and molybdenum. Thermal blankets made from TREO 2000 are immune to thermal shock and require no warning labels under Globally Harmonized System (GHS) for the classification and labeling of chemicals.

McAllister said that ideal end uses for TREO 2000 include appliances (e.g., self-cleaning ovens; high-temperature commercial cooking appliances), metals processing (e.g., stress relieving blankets; seals and gaskets; external boiler and duct insulation), power generation, petrochemicals, ceramic and glass, oven and furnace linings, exhaust insulation and heat shields.

About McAllister Mills:

McAllister Mills is a global leader in the manufacturing of precision-engineered thermal fabrics, insulation blankets, and cut and sewn products that are used in a wide range of industrial sectors and extreme environments. For more than 40 years, the company has operated a vertically integrated manufacturing facility located in Independence, Va., including yarn production, weaving, die cutting and coating. The company’s products include high temperature fabrics, silica fabrics, insulation blankets, custom insulation jackets, fabricated heat shields. For more information, visit mcallistermills.com or follow us on LinkedIn.