MD&A’s San Antonio Service Center can extend the service life of gas turbine components whose OEM service limit has passed or whose configuration is no longer suitable to operate. Significant savings can be realized by opting for lower-cost repaired spares instead of new parts.

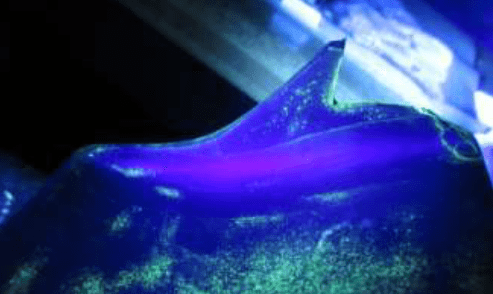

Elevated temperatures take a big toll on gas turbine components. Repair enhancements can extend a part’s life by slowing its degradation and pushing out its usable service life.

MD&A San Antonio Service Center experts have years of experience evaluating the life-limiting factors for gas turbine vanes or blades. Such factors include cracks, corrosion, wall thickness, and material condition. Cracks are often located at the platform or shroud. Smaller percentages occur at the blade tip, the blade airfoil, or the root.

Platform degradation can be reduced in many ways: by operating in baseload only (even though dispatch conditions may prevent that from being a practical solution), by pursuing a robust platform weld repair program, by improving the integrity of the platform coating, by undertaking TBC coating systems, and by making platform improvements.

Thermal mechanical fatigue cracks will eventually lead to platform failure. Design modifications often are required, incorporating a robust repair procedure. The life cycle enhancement process used by our experts exceeds OEM platform properties.

Our experts at the San Antonio Service Center combine years of experience with state-of-the-art equipment to deliver exactly the right solutions to you!

7FA 2nd Stage Blade Case Study

Our San Antonio facility evaluated two sets of 7FA 2nd Stage Blades to determine if they were capable to operate for a third service interval. The blades had operated through two service intervals and underwent one repair.

An x-ray inspection was performed on the components in their as-received condition. No areas of concern were detected, and no clogging was observed on the cooling holes.

An FPI inspection was performed to look for the presence of cracks. The area around the shroud radius was also evaluated for cracks. No major areas of concern were found during the preliminary FPI inspection.

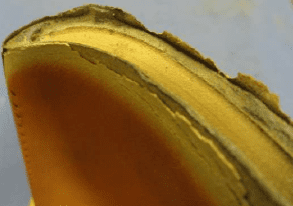

The condition of the internal coating was deemed acceptable and in good condition to operate for one more service interval. The external coating protected the external surfaces and was recommended for removal to allow a good FPI inspection of the hot gaspath surfaces.

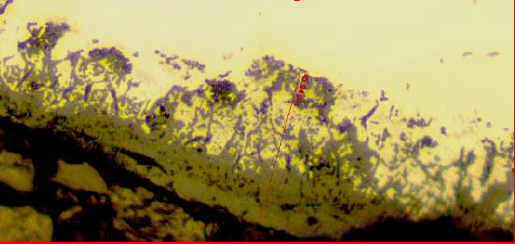

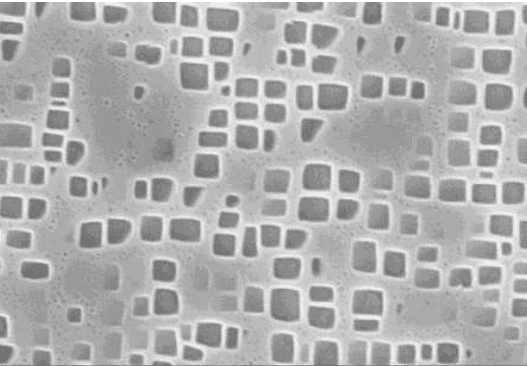

Microhardness readings taken at several blade locations showed a significant drop in the base material hardness where parts had been exposed to higher temperatures. These areas also showed significant degradation to the gamma prime structure under inspection by a Scanning Electron Microscope.

Hardness values after heat treatment demonstrated that the GTD 111 responded well to the process and the overall blade hardness values were improved.

For heat treatment, our experts utilize a vacuum heat treat furnace, where we control the heating and cooling of metals to alter their physical and mechanical properties. There is a pre-weld heat treatment, post-weld heat treatment, and a diffusion or aging heat treatment.

Samples were removed from the blades for stress rupture testing and in the as-received condition did not meet the minimum expected strength requirements for GTD 111. The samples tested after heat treatment exceeded the minimum requirements.

After the repair heat treatment, the stress rupture test time was improved by roughly 100 hours (tested @ 1600F / 50KSI). This demonstrates that the repair heat treatment was able to rejuvenate the parts sufficiently to operate for one more service interval.

In conclusion, our experts evaluated each component in the as-received condition and in the post-repair heat treated condition. Improvements in the alloy mechanical properties were evaluated to determine if the two sets are candidate for a Lifetime Extension (LTE) repair. Once established as candidates for Lifetime Extension, our experts employed repair practices to further extend the useable life of the components.

9FA 3rd Stage Blade Extended to 120,000 FFH

Our San Antonio facility received three 9FA 3rd stage blades where they underwent detailed inspections, including microstructural assessment and high-temperature testing.

Observations indicated galling in root serrations and seal pin surfaces, as well as the presence of two distinct casting houses to produce the row of buckets.

The scope of work included a visual inspection, dimensional measurements, and an x-ray inspection. Also included were a microstructural assessment, high-temperature mechanical properties testing, assessment of material condition at multiple locations, heat treatment of specimens to demonstrate the effects of repairs, and high-temperature mechanical property testing performed a post-heat treatment.

Inspections showed that the manufacturer’s heat treatment did not achieve full solutioning. All blades also displayed a two-phase gamma prime structure within each grain, indicating that the previous repair heat treatments were not optimized to achieve a good structure. In addition, all three blades had surface oxidation and depletion. Even so, all of the components were deemed repairable.

Additional repair work included grit blasting and polishing the gaspath surfaces to remove an oxide layer, a complete X-ray inspection, and HVOF coating and diffusion to reduce surface degradation.

Repair heat treatment was applied to several samples from the test blades, then evaluated to determine the material’s response to the heat treatment. The material responded well to the heat treatment on all three blades. The primary gamma transformed to a more cuboidal morphology, which provides for improved component creep life.

These third stage blades were evaluated and subsequently determined to be candidates for a Lifetime Extension (LTE) repair. The 9FA 3rd stage blades’ lives were extended to 120,000 FFH.

V94.3A4 2nd Stage Blade Extended to 75,000 EOH

A V94.3A4 2nd Stage Turbine Blade set had 50,000 EOH and operated through two service intervals, along with one repair performed by the OEM at 25,000 EOH.

Our San Antonio service center experts performed testing and evaluation on the blade set to determine if the hardware could be deemed repairable and serviceable for another interval, as well as an evaluation of the previous repairs.

One 2nd Stage Blade tested in the as-received condition had an internal and external Coating Evaluation, along with mechanical property and metallurgical properties inspection.

The other 2nd Stage Blade was evaluated in the post-heat-treat condition with mechanical properties and metallurgical properties inspection, and then an evaluation of metallurgical results. The heat-treated part was then evaluated for reparability.

Our experts performed a pre-weld heat treatment, post-weld heat treatment, and a diffusion or aging heat treat solution utilizing our vacuum heat treat furnace in our shop.

The external TBC appeared in good condition. However, the blade tip has significant oxidation. This is most likely due to the weld wire selected during the previous repair. All other inspections were normal.

One heat-treated blade’s metallurgical properties were then evaluated and compared to the other vane in the as-received condition. The evaluation confirmed that the heat treatment process would heal and improve the gamma prime structure.

Based on all the evaluation performed on the two 2nd Stage turbine blades, our experts determined that the full set was a viable candidate for life extension to 75,000 EOH.

The measurements of the blade tip cap indicated that there was sufficient material to perform a successful weld build up repair, so they removed most of the previous weld repair. Because of heavy oxidation on the blade tip, an oxidation-resistant alloy was used. Our weld repair procedure has demonstrated to provide excellent oxidation resistance during operation.

A coating system consisting of a NiCoCrAlY applied by HVOF and a TBC top coat was applied with our propriety coating. The V94.3A4 2nd Stage Blades’ lives were extended to operate to a total of 75,000 EOH.

Our San Antonio Service Center, or Gas Turbine Parts Service Facility, exemplifies best in service because of the deep experience in industrial gas turbine engineering and technology, repair techniques and equipment, and proven expertise on multiple frame gas components.

MD&A’s available Gas Turbine services range from full turnkey major inspections to rotor unstacking, gas turbine alignment, and control services. MD&A is a global full-service OEM alternative for services, parts, and repairs.

Call our MD&A Gas Turbine Services today at (518) 399-3616 or use our Contact form.

Proprietary Notice: WARNING – This document is the property of MD&A. You may not possess, use, copy or distribute this document or any information in it for any purpose, including without limitation to design, manufacture or repair parts, or obtain FAA or other government approval to do so, without MD&A express written permission. Neither receipt nor possession of this document alone, from any source, constitutes such permission. Possession, use, copying or disclosure by anyone without MD&A express written permission is not authorized and may result in criminal and/or civil liability. EAR commercial/Civil or Dual- Use Notice: WARNING — This document contains technical data the export of which is or may be restricted by the Export Administration Act and the Export Administration Regulations (EAR), 15 C.F.R. parts 730-774. Diversion contrary to U.S. law is prohibited. The export, re-export, transfer or re-transfer of this technical data to any other company, entity, person, or destination, or for any use or purpose other than that for which the technical data was originally provided by MD&A, is prohibited without prior written approval from MD&A and authorization under applicable export control laws. EAR Export Classification: EAR 99