Los Angeles sits alongside the world’s largest body of water, and naturally the city’s Department of Water & Power (LADWP) placed its generating stations along the shoreline to take advantage of that abundant resource for cooling. The LADWP built three coastal generating stations that provide the city with 2,162 MW, about 35% of the peak annual demand.

Well, at least it seemed like a good idea at the time. Updates to Section 316(b) of the Clean Water Act are expected to mandate that new, and some existing, power plants take additional steps to minimize fish mortality by plant cooling water intake structures. Those updates are scheduled for a late June 2013 release. However, in May 2010 the California State Water Resources Control Board issued a policy that all existing power plants using ocean water for once-through cooling (OTC) reduce their water usage by 93%.

To address this requirement, the LADWP has begun a $2.4 billion, multi-decade project to repower the three generating stations, not only reducing the water used but also creating a more efficient and flexible generating capacity.

“We have a variety of efforts under way that mesh together well,” says John Dennis, LADWP’s director of power system engineering. “They all work together to meet California regulations and energy efficiency goals, as well as any federal requirements. It is a pretty exciting plan.”

Reliability, Rates, and Reduced Carbon Footprint

Each year, the LADWP issues an updated Power Integrated Resources Plan (IRP), which provides the long-term planning for the utility’s power generation resources. The IRP is based on three key objectives: maintaining a high level of electric service reliability, maintaining competitive rates, and exercising environmental stewardship, including a reduced carbon footprint. These goals are often in tension.

The utility has already made significant progress toward its environmental goals. It has achieved the state mandate for 20% renewable energy, reducing its CO2 emissions by 23% compared to 1990, and is on target for reaching 33% reduction by 2020. Participants in LADWP’s Green Energy program were receiving 104 GWh annually from wind, solar, geothermal, and hydro facilities in several western states. The carbon reductions have come largely from reducing the importation of electricity produced from coal, including shutting down the 1,500-MW Mohave Generating Station, of which LADWP was a co-owner, and switching to natural gas and renewable generation.

Looking ahead, the IRP envisions further increases to the use of wind and solar and early shutdown of one of LADWP’s two remaining coal plants, while replacing the once-through cooling systems with dry condensers.

Although the plan does a good job of meeting the first and third of the key objectives outlined above, the second objective, maintaining competitive rates, does take a hit. According to the U.S. Energy Information Administration’s Electric Power Monthly for April 2013, California already had the 10th highest average cost of electricity at 13.02¢/kWh in Feb. 2013, 33% higher than the national average and roughly 45% higher than the average of the three states it borders: Oregon (8.39¢), Nevada (8.17¢), and Arizona (9.30¢). According to the IRP, the prices may rise to 22¢/kWh over the next decade, adding about $50 to the average residential customer’s monthly bill and $600 extra per month for a commercial or industrial customer using 6,500 kWh.

Maintaining reliable service remains a difficult chore, particularly in the face of increasing renewable usage and the OTC mandate. The California Independent System Operator (CAISO) says that this can be achieved through increased use of fast-response, high-efficiency combustion turbines.

“Gas-fired generation is our only means to do this right now until storage and demand response have matured to compensate for the fluctuations of wind and solar power,” says CAISO spokesperson Stephanie McCorkle. “We are actively educating policy makers and trying to propose a solution at the regulatory level as well to ensure that there is still enough conventional gas-fired generation available to us to be able to maintain reliability as we see more and more renewables added to the grid.”

LADWP manages its own grid, and sees quick-start gas generation as the way to accommodate more renewables in its generation mix and cut its use of ocean water.

“We looked at the technologies available and decided to go with advanced CT technology,” says Dennis. “We saw the need to be more flexible and have faster startup times, and this would integrate well with our variable renewable energy sources.”

The Haynes Project

As with any major, long-term generation strategy, LADWP’s IRP has to take into account a variety of competing factors and find the best mix of resources to meet its needs. In addition to cutting water use while providing energy efficiency and flexibility, generating stations must also provide enough reactive power to support the grid and allow the importation of power from remote renewable sources. This wasn’t a problem with the old boilers.

“Because the units were slow in starting up, we would always have something running,” says Dennis. “It may not have been the most efficient, but we always had some kind of spinning reserve connected, which provided inertia.”

When switching to the fast-start CTs, this would no longer be possible, and so the design had to find another way to provide voltage support.

LADWP has nine OTC units at its three generating stations. These plants were also getting on in years and needed a technology refresh anyway. The first of these stations to undergo repowering is the Haynes Generating Station in Long Beach. Built in the 1960s, Haynes has six natural gas steam units generating 1,600 MW total. In 2005, Units 3 and 4 were repowered with a 575-MW 2 x 1 combined cycle power block (Units 8–10) that is 40% more efficient and has 94% fewer emissions than the boilers it replaced.

“Our plan for Units 5 and 6 was to move on with another combined cycle block of similar size, using large frame units,” says Dennis. “We were close to having the environmental impact report done, but then the once-through cooling rule came out and we had to take a whole different approach.”

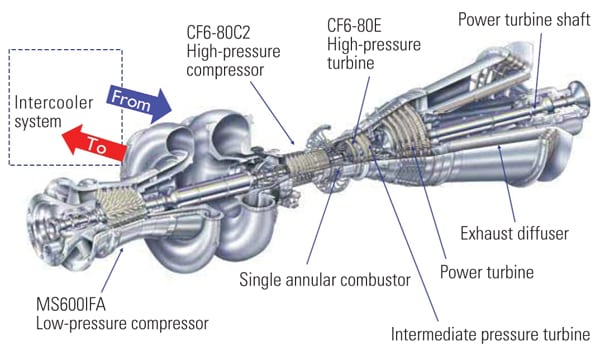

After looking at all the options, LADWP decided that it would be better to go with six 100-MW GE LMS100 fast-start, simple cycle combustion turbines rather than a single combined cycle unit. Although at full capacity the combined cycle unit would be more efficient, the LMS100s were better overall based on actual usage. Each LMS100 can go from 0 to 100 MW in 10 minutes, can operate at half-load, and has a 50-MW per minute ramp rate. As a result, this gives the Haynes plant the ability to rapidly respond to system fluctuations, operating anywhere from zero to all six turbines.

“If we had a 600-MW power block, we would have had a big jump of 300 MW,” says Dennis. “These can be run all the way up to the 600 MW and any kind of increments in between.”

This didn’t, however, solve the problem of having enough reactive power to support the grid. If there was a single large unit that was continuously operating and ramping up and down as needed, the generator would provide the necessary VARs to help pull in the power from the remote generating stations. But during periods when there is ample renewable power available, the LMS100s are offline.

To address this, LADWP had two of the LMS100s equipped with clutches from SSS Clutch Co., Inc. so they can operate as synchronous condensers. These overrunning clutches sit between the turbine and the generator. When the generator initially fires up, the clutch forms a connection so that it drives the generator. Then, when the unit is no longer needed for generation, the turbine can be ramped down. The clutch automatically disconnects the turbine from the generator, and the generator keeps spinning, synchronized to the grid and providing the necessary voltage support. Later, when active power is needed, the unloaded turbine fires up and the clutch automatically reconnects the two.

In another example of this application, CFE retrofitted an existing unit at its CTG Universidad Plant in Monterrey, Mexico, with an SSS clutch to provide additional reactive power to the downtown industrial district. This project was POWER’ s 2011 Marmaduke Award winner. (See “CFE Extends CRG Universidad Unit 2’s Life with Conversion to Synchronous Condenser” in the August 2011 issue at https://www.powermag.com. Two additional LMS100 project reports are available online about the Groton Generating Station, September 2007, and the Panoche Energy Center, September 2010.)

“During extremely slow periods, we could go all the way down to zero generation and just keep the generator synchronized and acting as voltage support to the system,” says Dennis. “This gives us greater overall flexibility and replaces the old technology that took so long to start up.”

|

| 1. Six-pack plant. LADWP purchased six General Electric LMS100 simple cycle combustion turbines for its Haynes Project because of the machines’ fast start and excellent part-load efficiency, and because the units may be used as synchronous condensers. The LMS100 is GE’s first aeroderivative gas turbine rated higher than 100 MW. Source: General Electric |

Eliminating the Water

On Sept. 29, 2011, LADWP broke ground on the $782 million repowering project. The major equipment started arriving in mid-March 2012, and by April 2, three 190-ton turbines, 182-ton generators, and 100-ton dry cooling towers had been delivered to the site, with the other three units arriving last summer. Testing and tuning began last November and continued through April 2013, so the peakers will be ready for the 2013 summer season.

|

| 2. Water, water, everywhere, but not a drop to cool. The first two units are shown here during construction, with the generator and the LMS100 to the right of the foreground and the intercooler in the left background. The units do not use any ocean cooling water, unlike the units they are replacing. California requires generators to severely reduce the amount of ocean cooling water used in future plants. Courtesy: LADWP |

“We are targeted for substantial completion in June of 2013, and everything is looking on schedule for that to happen,” says Dennis.

In the meantime, the utility is progressing on its second repowering project: replacing the three units at the Scattergood Generating Station near Los Angeles International Airport. As of this writing, LADWP is finalizing contracts before beginning work to replace Unit 3, which is scheduled for completion at the end of 2015. The Scattergood project will include a mix of simple cycle units and combined cycle units with similar options for clutches as at Haynes. Either way, it will include dry cooling towers.

Next on the list are the other two units at Scattergood, then two more units at Haynes, one unit at the Harbor Generating station, and then finally replacing the combined cycle units installed at Haynes by 2029. At that point, the LADWP will no longer be using any ocean water for cooling at any of its plants.

“Not only can we meet our energy demands,” says Dennis, “but incrementally step down the use of ocean water, increase our use of renewable energy from 20% to 33% by 2020, increase our energy efficiency by 10% by 2020, and reduce our CO2 and NOx emissions.”

—Contributed by Joe Zwers, a freelance writer from Glendale, Calif., specializing in engineering and technology.