|

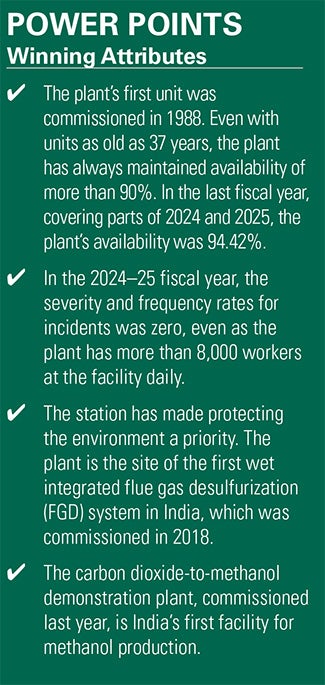

The NTPC Vindhyachal Thermal Power Station, with an installed generation capacity of 4,783 MW, comprises 13 coal-fired units and includes solar and hydropower installations. The plant continues to implement advanced emission-control technologies as part of India’s broader decarbonization strategy.

Data from Grid India, that country’s federal power grid regulator, shows both coal and natural gas–fired electricity output in India has declined this year, with generation from renewables, including hydropower, and nuclear power rising. India continues to rely on coal-fired units—government data showed 806 such units in service as of May 2025—for much of its power generation, though, with coal plants generating 60% and sometimes as much as 70% of the country’s total supply of electricity.

The Indian government has increased its focus on reducing emissions from the coal sector, with mandates for installing flue gas desulfurization (FGD) systems. Power generators are taking other steps to reduce their environmental impact, as the Indian government has committed to having net-zero carbon emissions by 2070.

The NTPC Vindhyachal Thermal Power Station is a prime example of India’s efforts to reduce pollution while recognizing the need for more electricity. Vindhyachal, the largest power plant in India with 4,783 MW of generation, in recent years has added solar (15 MW) and hydropower (8 MW) to the station, while continuing to operate 13 coal-fired units with 4,760 MW of capacity. The plant, whose first unit was commissioned in 1987, with the last coming online in 2015, is located in Singrauli district, in the Indian state of Madhya Pradesh.

|

|

1. Flue gas desulfurization (FGD) systems are a highlight of the NTPC Vindhyachal plant. All 13 of the facility’s coal-fired units will have FGD systems installed by mid-2026. Courtesy: NTPC |

Rajeev Kumar, an additional general manager at NTPC, said all 13 of those units by the middle of 2026 will have FGD systems (Figure 1) installed as part of NTPC’s ongoing desulfurization strategy. “NTPC has taken steps with the objective toward decarbonization, and to be positioned as a low-carbon electricity generator to support India’s climate change targets,” said Kumar, noting NTPC wants to take a lead role because of its status as India’s leading integrated power company. NTPC has plans to achieve 60 GW of renewable capacity by 2032.

“NTPC Vindhyachal is the largest power plant of India [and] it is the only power plant in India that utilizes thermal [coal], hydropower, and solar power to produce electricity,” said Kumar. “The thermal [coal] plant has 13 units; six have 210 MW of generation capacity, and seven have 500 MW of capacity.”

Kumar told POWER: “At present, a flue gas desulfurization system has been commissioned in Units 10, 12, and 13, which are each 500-MW units. The Unit 8 and Unit 11 FGD system trial operation is in progress”; Kumar said commissioning was expected in September. “The FGD target date for Units 9 and 7 is October of this year, respectively. The target date for Units 1 to Unit 6, is April 2026,” said Kumar.

The decision to add renewable energy to the power station came as India was first looking at renewable energy. Kumar said that “15 MW of commercial solar was planned in 2012, and that plant was commissioned in 2014. NTPC made the decision to promote solar generation in India when solar plants were in nascent stage in India. To promote hydro energy, an in-house study was done to use CW [cooling water] discharge canal water to generate electricity through a small hydro plant with 8 MW of capacity.”

Additional Renewable Power

Adding a hydropower system at NTPC Vindhyachal made sense, as hydropower has been India’s largest renewable energy resource. Hydro produced nearly 12% of the country’s electricity in recent years, and the government in August approved construction of a new 700-MW hydropower dam in Arunachal Pradesh, which officials said is in response to China’s recent announcement of the potentially 60-GW Motuo Hydropower Station on the Yarlung Tsangpo river. That river flows south into India, with Indian officials concerned about China’s efforts to control the river and negatively impact India’s economy.

Though the hydro output from NTPC Vindhyachal is small, Kumar noted its importance in the country’s strategy to increase hydropower generation, particularly at sites with energy infrastructure already in place.

“The hydropower water source is from open-cycle CW discharge canal from the NTPC Singrauli power plant,” said Kumar. “Water after being used in the NTPC Singrauli plant is returned to Rihand dam via a discharge canal. Two units of horizontal tubular S-type Kaplan turbines, each 4 MW, with automatically adjusted guide vanes and automatically adjustable runner blades are installed. The turnkey project for turbine and generator work was awarded to Jyoti Limited.”

Solar power generation is rising rapidly in India, and the National Solar Energy Federation of India (NSEFI) recently asked the government to accelerate transmission and battery energy storage projects in an effort to get even more solar online. The federal power ministry has said it is fast-tracking interstate transmission lines to support renewable energy connections.

Kumar said the solar power at NTPC Vindhyachal provides a model for adding solar at sites with transmission infrastructure already in place. “The 15-MW solar is based on monocrystalline photovoltaic cells, manufactured by BHEL [Bharat Heavy Electricals Limited],” said Kumar, noting BHEL was awarded the turnkey project. “There is a total of 62,640 PV modules in 2,610 strings.” The plant is adding 20 MW of commercial solar, with commissioning expected by October 2026.

Producing Methanol

NTPC Vindhyachal also is pioneering an effort to use the carbon dioxide (CO 2) captured at the power plant to make fuel, in this case methanol. “The carbon dioxide-to-methanol [CTM] demonstration plant is India’s first power plant for methanol production based on CO 2 captured from flue gas,” said Kumar. “We are working on following four areas for utilization of methanol produced in our 10 TPD [tonnes per day] methanol facility.” Those four areas include:

- ■ Methanol firing in one of NTPC’s gas turbines.

- ■ Methanol co-firing in the boiler of the thermal plant.

- ■ A methanol-driven engine generator.

- ■ Selling the fuel in the open market.

Methanol has several applications in India. It is used as chemical feedstock, and can be a fuel alternative. Officials have said methanol is used in many industries, such as chemicals, plastics, textiles, and pharmaceuticals. India also is looking at using methanol as a biofuel to help reduce a reliance on imports of fossil fuels.

Multiple Equipment Suppliers

Major equipment suppliers for the coal-fired units at NTPC Vindhyachal include BHEL (500-MW boilers and turbines); Krasny Kotelshchik (210-MW boilers); and LMZ (Leningradsky Metallichesky Zavod, 210-MW turbines). BHEL also supplied generators for the larger units. The FGD systems for Units 1 through 12 were supplied by Larsen & Toubro (L&T India); General Electric (GE) supplied the FGD for Unit 13.

Major equipment suppliers for the coal-fired units at NTPC Vindhyachal include BHEL (500-MW boilers and turbines); Krasny Kotelshchik (210-MW boilers); and LMZ (Leningradsky Metallichesky Zavod, 210-MW turbines). BHEL also supplied generators for the larger units. The FGD systems for Units 1 through 12 were supplied by Larsen & Toubro (L&T India); General Electric (GE) supplied the FGD for Unit 13.

Kumar said the power station enforces a “Safety First” culture to ensure zero incidents and maintain a safe environment for more than 8,000 workers. The facility is segmented into 37 safety zones categorized by risk levels—high, medium, and low—each managed by dedicated teams based on hazards identified through Hazard Identification and Risk Assessment (HIRA) analysis. Kumar said the plant is notable for its safety record, with no fatal accidents, and only four reportable incidents, in the past three years—and just one in the past two years.

“The 35-year-old Unit 3 operated continuously for 644 days before being stopped on Jan. 9, 2025, which is the second-best ever [continuous operation] across India,” said Kumar, who noted the record is 702 days of continuous operation, held by another NTPC plant. “A few years back [Unit 3 at NTPC Vindhyachal] had 559 days of continuous operation.”

Notably, the power station has scored marks of 601 or higher in NTPC’s business excellence assessment for three consecutive years. Kumar said the plant also achieved the highest slot (575 to 599) in CII–EXIM Bank Award for Business Excellence in 2024, an award jointly administered by the Confederation of Indian Industry (CII) and the Export-Import Bank of India (EXIM Bank).

“Business Excellence encompasses all facets of an organization, serving as a foundation for strategy formulation and effective process execution,” said Kumar. “The assessment provides an opportunity to identify both strengths and areas for improvement. A score between 600 and 699 is considered outstanding, reflecting strong potential for world-class performance. Stations achieving scores above 600 are often regarded as role models, frequently selected for benchmarking and for sharing best practices. These scores are not merely symbolic—they shape reputation, strengthen stakeholder confidence, and open doors to future recognition, funding, and strategic partnerships.”

—Darrell Proctor is a senior editor for POWER.