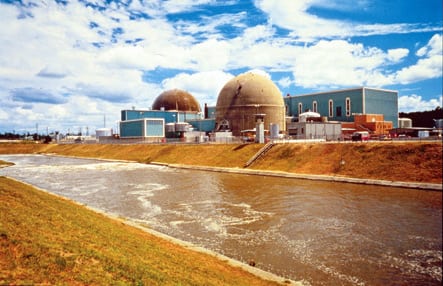

Dominion applies for new Virginia reactor

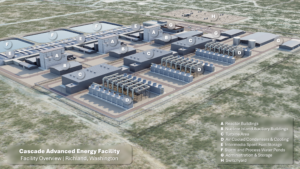

In late November, Dominion became the third power company to formally propose building what would be the first new U.S. nuclear unit in more than 30 years when it filed an application for a combined construction and operating license (COL) license with the Nuclear Regulatory Commission. The reactor would be constructed on the grounds of Dominion’s North Anna nuclear plant (Figure 1) in Louisa County, Va. North Anna is already home to two reactors with a combined capacity of 1,834 MW.

|

1. Virginia is for nuke lovers. Dominion has applied for a combined construction and operating license for a third unit at its North Anna nuclear facility in Virginia. Courtesy: Dominion

|

If the approval process goes smoothly, Dominion could break ground by 2010 and have the new unit on-line by 2015. It would be based on the 1,520-MW GE-Hitachi Economic Simplified Boiling Water Reactor (ESBWR) design. With the filing, Dominion becomes the first U.S. investor-owned, regulated utility to submit a full COL application.

Exelon Nuclear earlier announced plans to use the ESBWR for a plant it is considering building in Texas. The company is studying locations in Matagorda and Victoria Counties as potential sites.

Like most utilities considering building new nuclear capacity, Dominion has spread the financial risk of the North Anna project across several partners. Dominion will pay only about $60 million of the $500 million needed to reach the construction phase in Virginia. The balance will be paid by project partners, which include GE-Hitachi and Bechtel Corp., and by the Department of Energy (DOE) under a cooperative agreement to have the North Anna project serve as a “reference” application for other utilities considering applying to build an ESBWR.

A second utility consortium, NuStart Energy Development LLC, is working with the DOE under a similar agreement to develop a reference COL application for Westinghouse AP1000 reactors.

ABB commissions world’s largest SVC

In early December, ABB announced that it had completed work on what is now the world’s largest static VAR (volt-amperes reactive) compensator (SVC).

The SVC, which entered service on December 5, is at Allegheny Power’s Black Oak Substation near Rawlings, Md. (Figure 2). The unit will enhance the reliability of Allegheny’s 500-kV Black Oak-Beddington transmission line—one of the most congested on the Pennsylvania-New Jersey-Maryland (PJM) Interconnection network—by quickly changing reactive power levels to stabilize line voltage. The SVC also will boost transmission capacity on multiple 500-kV lines in the PJM region.

|

2. VAR sets record. ABB recently commissioned the world’s largest static VAR compensator at Allegheny Power’s Black Oak substation. Courtesy: ABB

|

The Black Oak installation uses ABB’s MACH 2 control system both to manage the operation of the SVC and to switch on and off the 500-kV capacitor banks on the lines entering and leaving the substation.

The project was initiated as part of PJM’s regional transmission expansion plan to identify the upgrades and additions needed to ensure reliability of its multi-state transmission system. “The Black Oak SVC will benefit millions of customers by providing a new level of reliability to a critical transmission line serving the Mid-Atlantic region,” said David E. Flitman, president of Allegheny Power. “Further, allowing more power to flow on existing lines is an important step in keeping pace with the region’s increased demand for electricity.”

The Black Oak SVC turnkey project was completed in just 14 months—no mean feat, given its size, complexity, and scope. “Collaboration was essential to meeting the aggressive timeline,” said Flitman. “If it were not for the Allegheny and ABB teams working so closely together, we simply would not have been able to get the system on-line this quickly.”

Google Earth adds air quality data

We’ve all done it—fired up Google Earth and zoomed in on our home or a famous landmark to see how sharp satellite photos have become. You still can’t read license plates, but the view from space is captivating, and “flying” from one target to another is a trip.

|

3. Air Google. Thanks to a partnership with the U.S. EPA, users of Google Earth can now call up near-real-time air quality data for any location in America. Source: Google Earth

|

Google recently integrated near-real-time scientific air quality information from the U.S. Environmental Protection Agency (EPA) directly into Google Earth. The program accesses the EPA’s AIRNow database hourly, enabling its new Air Quality Index to display current air quality conditions at any U.S. location. Figure 3 shows two readings for Phoenix called up a month ago.

For more information on AIRNow, and easy instructions for using it with Google Earth, go to www.epa.gov/region09/air/airnow.

Alstom supplies integrated solar/CC project in Morocco

In late October, Alstom was awarded a $234 million contract by Spain’s Abengoa Group, on behalf of Morocco’s Office National d’Électricité, to supply two GT13E2 gas turbine generators, one steam turbine generator, and three air-cooled turbogenerators to the Aïn Béni Mathar power project. The deal includes a 21-year service contract under which Alstom will maintain and help support the operation of the plant, 60 miles from Oujda.

The project seeks to become the world’s first integrated solar combined-cycle power plant. It will have a generating capacity of about 470 MW, 20 MW of which will come from energy collected by a 1.97 million ft2 array of single-axis-tracking cylindrical parabolic mirrors in parallel rows. Abengoa Group received a $43 million grant from the World Bank to develop the solar part of the project.

On the solar side, each bank of mirrors is equipped with a linear parabolic reflector that aims reflected sunlight on a receiver at the focus of the bank’s parabola. The energy delivered to the receiver heats a working fluid that’s circulated through it. A series of heat exchangers extracts the energy and feeds it to two heat-recovery steam generators (HRSGs) into which the two gas turbines exhaust (Figure 4).

|

4. Technology fusion. A simplified block diagram of the 470-MW integrated solar combined-cycle plant that Alstom is building in Morocco. Source: Alstom

|

As the figure shows, the two gas turbine generators are part of a conventional 2 x 1 combined-cycle configuration. The two systems are tightly integrated: Water used in the solar side’s steam generator is taken from the HRSG’s economizers, and steam generated by the solar field is injected into the superheaters of the same HRSGs. Both flows of steam, generated by the solar field and by the HRSGs, are expanded together by the single steam turbine.

DOE updates coal plant database

Interested in a comprehensive and current list of U.S. coal plants and projects? Check out the latest release of the DOE’s 2007 Coal Power Plant Database. Available as an 8.6-MB Excel spreadsheet, a 20.8-MB Excel pivot table, or a 24-MB Access database, it is maintained by the Office of Fossil Energy’s National Energy Technology Laboratory. The database, covering more than 1,900 plants, can be found at www.netl.doe.gov/energy-analyses/technology.html.

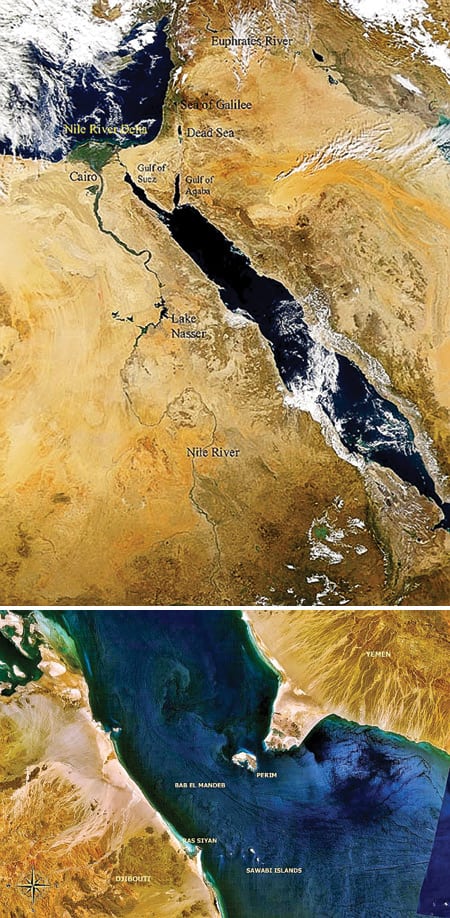

Dam the Red Sea?

Building a dam across the Red Sea at Bab al Mandab (“Bab El Mandeb” on Figure 5), the 20-mile-wide strait separating Yemen and Djibouti, and using it to generate hydropower could help meet the growing electricity demand of millions of people in the Middle East without further depleting the region’s oil and natural gas reserves. But such a massive engineering project also could take a ruinous toll on the local environment and displace countless people from their homes.

|

5. Moses crossed another way, at the other end. Researchers at Utrecht University in The Netherlands suggest that 50 GW could be generated by a 20-mile-wide dam across the Red Sea near its southern end. Courtesy: NASA

|

Those are the overall conclusions of a research report recently published in the International Journal of Global Environmental Issues, from Inderscience Publishers. In the report, Roelof Dirk Schuiling of Holland’s Utrecht University and his colleagues discuss the costs and benefits of what could be the most ambitious engineering project ever.

According to the authors, existing technology allows us to shift and shape the earth on a relatively large scale, including damming rivers to create artificial lakes big enough for megawatt-scale power generation. In the near future, it may even be possible to dam the Red Sea. Such a barrier would stem the flow of seawater from the Indian Ocean into the sea, which is highly evaporative.

Schuiling, a geochemical engineer, says that a dam at Bab al Mandab could be used to generate as much as 50 GW. By comparison, the 33 hydroelectricity generators at Grand Coulee Dam on the Columbia River in central Washington have a peak summer capacity of 7.1 GW, making it the largest power plant in the U.S., according to the DOE’s Energy Information Administration.

“Such a project will dramatically affect the region’s economy, political situation and ecology, and the effects may be felt well beyond the physical and political limits of the project,” the authors say of the dam. For example, it would cause major disruptions to military and commercial ship traffic (Figure 6).

|

6. Five acres of diplomacy. Building a dam that would put an end to all ship traffic, including oil supertankers, into and out of the Red Sea would definitely not be popular with the energy-hungry industrialized world. Courtesy: DefenseLink

|

Schuiling and his colleagues wrote that the costs and time frames of such a massive project are way beyond normal economic considerations. However, someone is sure to at least consider it, because 50 GW of hydro capacity would offer future generations a sustainable, CO2-free alternative to the continued burning of huge quantities of fossil fuels.

Complying with CWA Section 316

In October 2007, more than 100 people met at the headquarters of Tri-State Generation and Transmission Association in Westminster, Colo., for an EPRI-sponsored workshop on Section 316(a) of the Clean Water Act (CWA). This section of the CWA regulates the thermal effluents of once-through power plant cooling systems. It provides for variances from both technology-based limits and water quality standards if a plant can demonstrate that its thermal discharge “will assure the protection and propagation of a balanced, indigenous population of shellfish, fish, and wildlife in and on that body of water.” The 316(a) program was very active in the 1970s, when thermal dischargers conducted studies to determine whether they qualified for a variance.

“Even if the Clean Water Act has not changed in 35 years, the world has and continues to do so,” said Dr. Robert Goldstein, a senior technical executive of EPRI. “Water issues such as thermal discharge, impingement and entrainment, total maximum daily loads, effluent guidelines, and availability are converging. We have come together as a concerned community of power plant employees, regulators, consultants, researchers, professors, and students to consider a mixture of old and new topics that excite the imagination and call out for creative scientific, technical, and policy solutions.”

It ain’t broke—it’s just stale. Over two days, attendees heard more than 25 presentations on 316(a) from technical, legal, and regulatory perspectives. Among the technical topics covered were the development of water quality and thermal standards, thermal response characterization, thermal modeling, recent advances in cooling technologies, and the interplay between 316(a) and 316(b).

Some speakers discussed 316(a) from more than one perspective. For example, keynoter Chuck Coutant provided an overview of the past 60 years of attempts to set temperature criteria and standards to protect aquatic life. He pointed out that although regulatory efforts to control potential adverse effects from thermal discharges have been ongoing since the mid-1960s, there is no consistent framework within which states develop and implement protective water temperature quality criteria.

Deborah Nagel, industrial branch chief of the EPA’s Water Permits division, discussed the specific requirements of applications for a 316(a) variance. She also said that, from the agency’s perspective, state permitting authorities are not implementing the section consistently or correctly.

To improve the situation, the EPA expects to update its 316(a) technical guidance document, originally drafted in 1977, soon. “The 316(a) guidance manual has served us well for 30 years, but it is certainly due for updating,” said Chuck Coutant. “The basic structure of using retrospective (no prior harm) and predictive (thermal requirement data for organisms) approaches for demonstrating a balanced community remains strong. But the guidance needs to [reflect] a number of administrative and judicial decisions [since 1977], such as including managed, non-indigenous fish species and not expecting a return to pristine conditions. Also, several indices of community health have been developed that are very useful for evaluating the balance of aquatic communities, which is the crux of Section 316(a).”

While the EPA works toward updating the guidance document, several states are making an effort to revise long-outdated water temperature standards. Presentations by Erich Emery of the Ohio River Valley Water Sanitation Commission (whose members represent Illinois, Indiana, Kentucky, New York, Ohio, Pennsylvania, Virginia, and West Virginia), Lareina Wall of Colorado-based GEI Consultants, and Mike Wenholz of Wisconsin’s Department of Natural Resources discussed the status of updates to thermal standards in their respective states.

Research updates. Several workshop presentations updated scientific research on thermal response characterization. Rob Reash of American Electric Power discussed the issues involved in comparing laboratory and field tolerances for fish. Tamara Pandolfo of North Carolina State University presented her data on freshwater mussel sensitivity to a range of water temperatures, which showed that the presence of a secondary toxicant can make mussels more sensitive to temperature stress. Telemetry and other state-of-the-art tools for evaluating impacts of thermal discharges on fish were presented by Tim Brush of Normandeau Associates.

One-third of the presentations consisted of recent, site-specific case studies. Terry Cheek of Geosyntec Consultants and Bill Evans of Georgia Power described the drivers of Georgia Power’s decision to retrofit the cooling towers of three of its plants to prevent fish kills under extreme conditions, and the implications of doing so on the viability of the 316(a) regulatory option. David Lee of We Energies shared the 316(a) demonstration process, including thermal plume modeling, used to prepare the Oak Creek Expansion Project’s Wisconsin Pollutant Discharge Elimination System (WPDES) permit application.

The conference took on an international flavor as folks from France, the Netherlands, and New Zealand discussed their countries’ plant cooling water policies. Yves Souchon of Cemagref, a French public research institute focusing on land management issues, and Cecile Delattre of Électricité de France presented a summary of the thermal discharge regulations in their nation and some results of biological monitoring at power plant sites. Maarten Bruijs of the Dutch consultant KEMA described a field study on the influence on fish behavior of higher water temperatures in the cooling water discharge of Claus Power Plant in the Netherlands. Finally, Jacques Boubee of the National Institute of Water and Atmospheric Research summarized New Zealand’s generation and environmental regulations and the challenges in meeting them at Huntly Power Station, the country’s biggest thermal plant.

Hot topic. A common theme of many presentations was the effect of climate change on plant environments. For example, Yves Souchon and Cecile Delattre explained that Europe’s heat wave of 2003 raised questions that France’s environmental policymakers are still struggling to answer. As for climate change’s effect in the U.S., Deborah Nagle of the EPA said it was creating more areas with prolonged dry and wet conditions and generally increasing the ambient temperatures of waterbodies.

The workshop closed with several presentations on emerging issues and future research needs. E. Eric Adams of MIT discussed advances in thermal plume modeling. Judson White and John Waddill of Dominion Resources explained the performance rationale for hybrid cooling, called for in their company’s recent COL application for a proposed new unit at the North Anna nuclear station. Tim Hogan of Alden Research Laboratory discussed the benefits of colocating power plants with desalination or liquefied natural gas facilities. In such arrangements, the power plant’s discharge can serve as the water supply for either type of facility, thereby reducing costs and enabling the sharing of research, construction, permitting, and monitoring resources.

The workshop was organized by a steering committee consisting of Chuck Coutant (retired); Doug Dixon and Robert Goldstein of EPRI; Raymond Harrell and Ron Lewis of Duke Energy; Chantell Johnson of the host (Tri-State); Christine Lew and Bill Mills of Tetra Tech; Dave Michaud of We Energies; and Rob Reash of American Electric Power.

EPRI will publish the workshop proceedings early this year. For more information, contact Robert Goldstein at rogoldst@epri.com.

—Christine Lew, PE, a senior enviromental engineer for Tetra Tech Inc. (www.teratech.com).

POWER digest

News items of interest to power industry professionals.

Big CC plant coming to Texas. In early December, Panda Energy Inc. announced its intention to build, own, and operate a 1,000-MW combined-cycle plant in an industrial area of Temple, Texas, on Interstate 35 between Waco and Austin. The area is one of the 10 densest and fastest-growing population centers in the U.S. Nearly half of the state’s 21 million citizens live within 50 miles of I-35.

“This plant will help meet the future energy needs of our growing state and strengthen the economy of central Texas” said Robert Carter, Panda Energy’s chairman and CEO. “With little or no power plant construction having occurred during the past five years, state and local officials are being farsighted in working now to enhance the future reliability of the region’s power supply. We look forward to working with them in bringing this project to completion.”

Panda told POWER that it is deciding between two different configurations for the gas-fired plant. One option is a Siemens Power Generation FlexPlant10, using SCC6-5000F combustion turbine generators in combined-cycle mode, with four 1 x 1 power blocks. The other is a General Electric Frame 7FA-based plant with two 2 x 1 power blocks. Panda noted that the choice will depend on the units’ availability and other market factors when the time comes to specify major equipment.

Temple Generating Station will be located on a 250-acre site at the South Temple Industrial Park. It should take about two years to build, assuming timely receipt of regulatory approvals and financing. Panda has already filed for an air permit with the Texas Commission on Environmental Quality. The company says it is designing the plant to maximize the use of reclaimed water, thereby conserving the state’s fresh water resources.

North Dakota to get new gasification plant. The North Dakota Industrial Commission and representatives of Great Northern Power Development LP (GNPD) and Allied Syngas Corp. have announced a $1.4 billion coal gasification project at South Heart that would produce pipeline-quality syngas.

The South Heart project would be a joint venture of GNPD and Allied. Both companies have subsidiaries that bring strategic value to the table. For example, Great Northern Properties LP, a GNPD affiliate, owns a substantial amount of the coal reserves that would fuel the plant. Meanwhile, Allied’s Envirotherm GmbH affiliate is a co-owner of the advanced British Gas Lurgi (BGL) gasification technology that the project would use. BGL’s other owner is Advantica Ltd. Advantica and Envirotherm will provide the technology license, design, and technical support for the gasification process.

The project will use seven BGL gasifiers to turn North Dakota lignite into as much as 100 million cubic feet/day of pipeline-quality gas that could be sold locally or nationwide. According to the project partners, the gasification plant will also produce many of the chemical by-products needed to manufacture fertilizers or serve as feedstocks for chemical plants. This project also will capture CO2, which could then be sequestered in underground brine or shale formations in and near North Dakota or used to enhance recovery of oil from nearly depleted nearby fields.

Construction is slated to begin in late 2009 or early 2010 and wrap up in 2012.

NRG, Powerspan announce large-scale CCS demo. In a recently announced memorandum of understanding NRG Energy Inc. and Powerspan Corp. agreed to demonstrate at commercial scale the latter’s ECO2 technology for carbon capture and sequestration (CCS). (See POWER, October 2007, p. 54, for details of the ECO2 process.)

ECO2 is a post-combustion, regenerative process that uses an ammonia-based solution to capture CO2 from the flue gas of a power plant. Once the greenhouse gas has been captured, the solution is regenerated to release CO2 and ammonia. The ammonia is then sent back to the scrubbing process, leaving the CO2 in a form suitable for geological storage. Ammonia is not consumed by the scrubbing process, which creates no by-products. Powerspan says ECO2 technology is applicable to both existing and new coal-fired plants and is particularly economical for plants that use ammonia to reduce their NOx emissions.

To date, CCS demos have only been conducted on pilot-scale coal plants with capacities between 1 MW and 5 MW. This demo will take place at NRG’s W.A. Parish plant near Sugar Land, Texas, on quantities of flue gas equal to those of a 125-MW unit. The project’s goal is to capture and sequester about one million tons of CO2 annually.

As at the South Heart project, the CO2 captured by the Parish project may be used to enhance oilfield recovery operations in the region. The demonstration facility, which is being designed to remove 90% of the CO2 from a flue gas stream, is expected to be operational in 2012.