Meeting increasing worldwide demand for wind energy depends on reliable turbine performance, and performance can significantly benefit from optimized main shaft and gearbox bearing selection. Wind turbine bearings handle enormous thrust and radial loads that are continuously changing, requiring significant engineering to enable the best possible performance in these critical applications. When it comes to maximizing the useful lifespan of wind turbines throughout the world, main shaft and gearbox bearing selection are some of the most critical decisions that can be made.

The demands of the bearings have changed throughout the evolution of wind power. During the early days of wind turbine development, sub-megawatt class wind turbines typically used standard spherical roller bearings (SRBs) in the main-shaft position with significant success. But turbines have grown increasingly larger and more powerful. Today’s onshore turbines range from 1.5 MW to 3 MW, where offshore applications are usually more than 3 MW and can grow to more than 10 MW.

Thus, the demands of the main-shaft bearing and those throughout the gearbox have evolved. Increased stresses in larger turbines are testing conventional bearing design, particularly in the main-shaft position. And the ongoing success of major wind applications around the world is influenced by the industry’s evolving understanding of how, why, and which bearings can deliver the necessary performance.

Taking Stock of Recent Field Performance

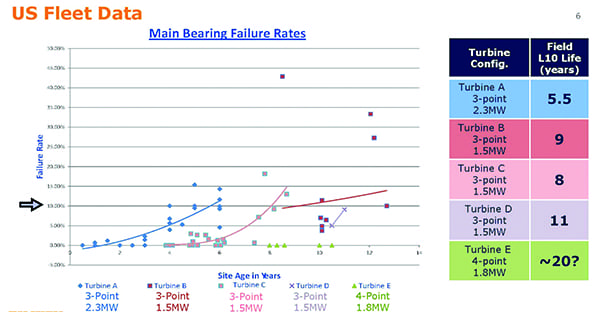

While many new wind turbines have simply scaled-up traditional turbine design, field performance has shown that this isn’t the answer, and a growing wealth of data bears this out. Damage and failure modes are occurring sooner than many wind farm operators have expected, leading to unforeseen repair and maintenance needs, and lapses in performance that can add up.

|

|

1. Main-shaft bearing failure rates have reached 10% or more as some wind turbines approach just six years in service. As turbine owners plan much-longer lifecycles, equipment below performance standards may require a main shaft and gearbox rebuild every 7 to 10 years. Courtesy: The Timken Company |

Onshore main-shaft bearing failure rates have been shown to reach 10% and higher as some equipment approaches just six years in service, below expected performance (Figure 1). Many wind turbine owners are increasing the expected time they plan to operate a turbine from 20 to 25 or 30 years. However, some under-performing sites require a main shaft and gearbox rebuild every 7 to 10 years. If each main shaft and gearbox repair, including crane costs, is assumed to cost about $300,000, operators could spend up to $1.2 million per turbine over the course of a typical turbine lifecycle.

More recently, opportunities to upgrade wind power performance on a broader scale have been identified. A growing number of older wind farms around the U.S. have taken the opportunity to repower, or upgrade, with more efficient turbines, better electronic systems, and lighter, longer blades that can help capture more energy with each rotation. Existing turbines are replaced with new generators and other new drivetrain components. These wind farms also have taken advantage of available tax credits, making repowering more attractive.

What hasn’t occurred in these hundreds of repowering projects, however, is the adoption of higher-performing bearings on a large scale. SRBs in use for the main shaft and throughout the gearbox are being replaced on a “like-for-like” basis, despite new data and research showing that alternative bearing technology—namely tapered roller bearings, or TRBs—demonstrates greater ability to perform under the unique circumstances of increasingly powerful wind turbine applications. Particularly in turbines that exceed 1 MW, TRBs are an option that shouldn’t be overlooked.

Spherical Versus Tapered Roller Bearings in Main-Shaft Applications

Comparing the performance of SRBs against TRBs in wind applications starts with understanding turbine designs that commonly and traditionally have used SRBs.

|

|

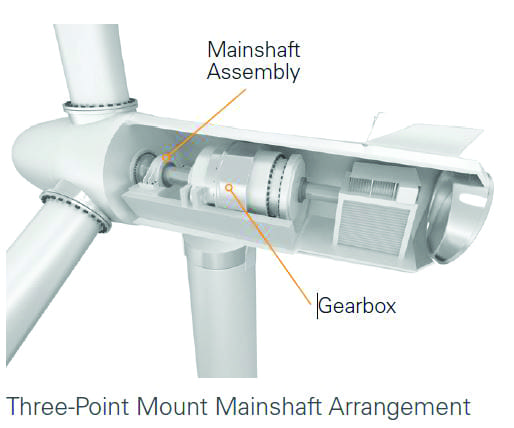

2. A three-point mount main-shaft system typically has a single support for the main-shaft load, with a single two-row spherical roller bearing (SRB) in front of the gearbox. Additional support points are located at the gearbox torque arms. Courtesy: The Timken Company |

A three-point mount main-shaft system (Figure 2) typically contains a single support of the main-shaft load with a single two-row SRB in front of the gearbox. There are two additional support points found at the gearbox torque arms, which yield three total support points. Three-point mount SRBs do have some distinct advantages in three-point systems, including a shorter nacelle package with reduced turbine mass; high system deflection and misalignment capabilities; and they are often an economically attractive choice.

But those advantages are offset by distinct disadvantages. For example, during significant thrust loading from strong wind gusts, the downwind (DW) row of the SRB becomes fully loaded, while the upwind (UW) row is typically unloaded. When combined with a constantly changing wind regime, the load-zone size and location changes, which can also result in unintended load transmission into the gearbox.

Due to the required radial clearance within the SRB, loads transfer to the planetary carrier bearings within the gearbox. As the SRB wears throughout operation, this additional load affects planetary gear meshes, and planetary gear and bearing loads, and has been shown to lead to significantly premature failure, resulting in higher costs. Due to these shortcomings, three-point systems are widely seen as unsuited for multi-MW turbines.

|

|

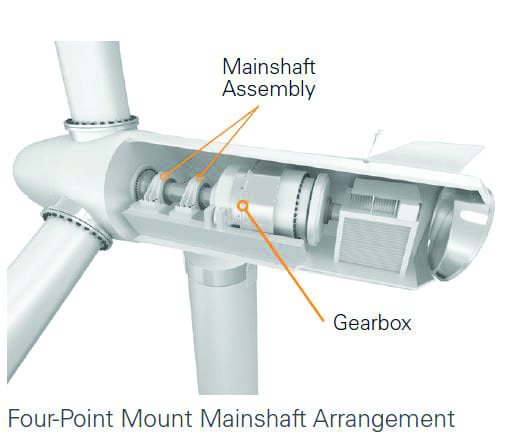

3. A four-point main-shaft system uses two gearbox torque arms to help support the main shaft, along with two, two-row SRBs for the main-shaft support. Courtesy: The Timken Company |

Similarly, a four-point main-shaft system (Figure 3) uses two gearbox torque arms to help support the main shaft along with two, two-row SRBs for the main-shaft support (which yields four support points, as the name implies). Normally, the UW floating SRB predominantly carries radial loads while the DW fixed SRB carries the majority of the wind thrust load. This is an improvement over the three-point design, but increasing evidence has shown premature damage to the DW fixed SRB, similar to what is commonly found in the three-point system.

The answer? More advanced SRB technology has started to make waves among some original equipment manufacturers (OEMs) and aftermarket customers. Wear-resistant SRBs, which use advanced coating technology, have demonstrated improved performance in three- and four-point mount applications. These coatings increase hardness and significantly help prevent adhesive wear, and simultaneously help polish and repair damaged raceways during operation. The enhanced finish increases the effective lubricant-film thickness, and reduces surface shear stress and the potential for surface-initiated damage. These coated bearings are an ideal solution for users looking for a direct replacement in the main shaft.

Elsewhere, a TRB main-shaft design can significantly increase reliability and improve overall system performance in multi-MW turbines. The TRB’s design helps optimize the overall powertrain system due to its ability to handle combined radial and thrust loads as well as to be preloaded, helping ensure system stability and rigidity, load sharing among rows, reduced load deflection into the gearbox, and more predictable roller-to-race interactions. Compared to an SRB, a single pre-loaded TRB can manage the combination of radial and thrust loads far more effectively.

Bearing Selection in the Gearbox

While the main-shaft bearing handles much of the heavy lifting, another means of improving reliability and performance of the entire turbine is to improve the robustness of the gearbox itself.

Most gearbox designs, across the different OEMs, remain similar, though the preferred bearing design varies. The market is split evenly between those using cylindrical roller bearings (CRBs) and TRBs throughout the gearbox, but more recently, some OEMs have introduced integrated bearings in the planet position.

The planet position is the most challenging within the gearbox, with moderate speeds, high and transient loads, and high heat all conglomerating in a small, constrained space. An integrated bearing in this position eliminates one critical damage mode in the gearbox, which exists in a non-integrated scheme between the outer ring and gear bore. This has the additional benefit of opening more space within the gearbox, enabling the use of a larger bearing that can more effectively carry higher loads.

Field Performance

From a field performance perspective, TRBs in the main-shaft position and integrated gearbox upgrade options remain relatively new; documented field installations have only occurred within the past few years. Therefore, long-term field performance is still being proven, but short-term results look positive. Along with field testing, extensive in-house analysis by The Timken Company along with the ongoing field trials shows reason for confidence in TRBs as a superior solution for critical wind applications.

Timken teams over the past several years have been closely analyzing TRBs installed and operated in three 1.5-MW units at two different sites for a major U.S. turbine owner. Service engineers have supported installation and alignment of housing and gearboxes, and have performed ongoing inspection. The results have shown several important proof points, including a measured 67% less main-shaft deflection versus recorded SRB performance data.

Further, Timken in 2017 evaluated a TRB taken offline for a repowering project. This TRB had been operational beginning in April 2015. After analysis, bearing grease remained in good condition with no signs of elevated wear materials, while cone and cup raceway profiles remained within design specification for a new product, all indicating no signs of wear. In short, the bearing remained in very good condition after two years of steady operation.

Evidence like this is all the more reason that OEMs and wind farm operators seeking to enhance performance in wind applications should investigate upgraded bearing technologies. The increasing viability of wind power depends on efficiency and performance, and bearings are a major part of the overall performance equation. ■

—Brian Ray is a chief industrial engineer for The Timken Company, a global

manufacturer of bearings and related components and assemblies.