Back in 2015, ground broke on a combined heat and power (CHP) facility in Florida. It was created as a partnership between Chesapeake Utilities Corp., its Florida Public Utilities (FPU) subsidiary, and Rayonier Advanced Materials Inc. (RYAM), and comprised a Solar Titan 250 gas turbine and a Rentech heat recovery steam generator (HRSG). Ten years on, how is the $40 million facility doing, how has the partnership worked out, and what lessons have been learned along the way? POWER magazine took a trip to the plant to answer those questions.

“The plant would not have been possible without the tight partnership between the local grid authority, FPU, and the industrial customer RYAM, as well as vendors such as Solar and Rentech,” said Mark Cutshaw, manager of Electric Operations with FPU. “The partnership has worked out well as RYAM is expected to renew the lease and existing contractual agreements.”

|

|

1. The Eight Flags combined heat and power (CHP) plant is situated beside a Rayonier Advanced Materials (RYAM) manufacturing plant. Nearby are the popular tourist destinations of Amelia Island and Fernandina Beach, Florida. Courtesy: Drew Robb |

The facility operates as Eight Flags Energy LLC, situated on the RYAM facility in Fernandina Beach on Florida’s Amelia Island (Figure 1). It is a subsidiary of Chesapeake Utilities. It is now almost halfway through a 20-year agreement in which it leases land from RYAM and provides that facility with low-cost steam and other services, as well as supplying power to the FPU grid.

Eight Flags Energy began producing power in June 2016. It supplies steam and hot water to the adjacent RYAM cellulose products manufacturing facility and 20 MW or so of electricity to FPU.

“Building the plant greatly improved flexibility at the cellulose facility and supported its production capability while reducing electricity costs for island residents,” said Cutshaw. “On average, the electricity from Eight Flags meets about 50% of Amelia Island’s energy needs.”

FPU obtains the power for its retail customers under a power purchase agreement with Eight Flags, which FPU estimated (when the facility opened) would save the utility about $28 million over the 20-year term. Eight Flags has six employees, runs 24/7, and has an average capacity factor of 97% over almost 10 years. It is quite common for the plant to have a 100% capacity factor for several months in a row. The number drops during the scheduled semi-annual and annual outages.

Gas Turbine Operations and Maintenance

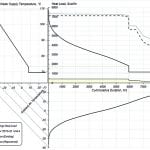

The facility is powered by a Solar Titan 250 gas turbine (Figure 2) that provides anywhere from 20 MW to 23.5 MW depending on conditions and time of year. It is a 16-stage turbo-compressor.

|

|

2. The Solar Turbine Titan 250 gas turbine at the Eight Flags CHP plant. Courtesy: Drew Robb |

Solar Turbines takes out and replaces the entire cold section (compressor) every 30,000 hours. The Solar Turbines long-term service agreement means Eight Flags is entitled to the latest version of the Solar Titan 250 after 30,000 hours of operation if a new or modified version has been released. As a result, it received the Titan 250E three and a half years ago, which provided 1,800 more horsepower to the unit.

“Every 30,000 hours, we get their best version upgrades as part of the contract,” said Cutshaw. “The latest upgrade introduced new actuators for the inlet guide vanes (IGVs) from Solar, which remain much closer to the prescribed calibration number.”

The semi-annual outage lasts two days and the annual outage lasts four days. Solar sends technicians onsite for each outage to inspect and maintain its turbine, as well as taking care of anything else needed in the interim. Solar monitors the turbine 24/7 remotely and sends advice, alerts, and other information. The original equipment manufacturer can look at the data from the turbine and predict trends that are occurring. Cutshaw added that Solar also sends service bulletins about issues found and advice gained from its large fleet of Solar Titan 250s.

A key maintenance action is to calibrate the IGVs during the annual outage. Solar also deals with the lube oil system, changes the lube oil filters, and performs other maintenance inspections and tasks when onsite.

An outage is scheduled for spring to change out a portion of the inlet air housing. This is being done as minor contamination has been found in the compressor due to corrosion in one part of the inlet air duct that has impacted turbine output slightly.

HRSG Operations and Maintenance

A Rentech HRSG (Figure 3) feeds steam to RYAM at 160 psi and 420F. The HRSG recovers about 70,000 to 75,000 pounds of steam per hour and has the capability to increase that amount using duct burners that add 125,000 pounds per hour of process steam for a grand total of 200,000 pounds per hour, if needed.

|

|

3. The Rentech heat recovery steam generator and associated steam lines that feed the RYAM manufacturing plant. It has operated reliably for a decade. Courtesy: Drew RobbDrew Robb |

Demineralized water provided by RYAM is channeled through a hot water economizer in the Rentech HRSG to increase the water temperature by 70F. This hot water is sent back to RYAM for use in production processes. Heating of demineralized water saves RYAM from having to generate its own power to heat the water. This also helps them to keep emissions low at their facility. Exhaust heat is also used to heat feedwater before it is sent into the HRSG.

As the duct burner’s steam output is not routed through the combustion management system, regulatory requirements impose a yearly cap on natural gas consumption for duct burning. Eight Flags has historically remained well below this prescribed limit.

A boiler inspection is scheduled every two years to ensure the boiler is operating within specifications. Eight Flags changes the pressure relief safety valves on the HRSG every two years, not due to problems, but as a precaution as they are critical to facility safety.

As the site is essentially in a salt marsh, it is in a highly corrosive environment. Additionally, the massive RYAN manufacturing plant generates plenty of dust from woodchips and debris. Standard preventive maintenance work is everything. Non-corrosion coatings are liberally applied to plant equipment and the HRSG. Vibration levels are regularly checked and onsite personnel inspect the air and water sides of the HRSG as well as the integrity of the tubes to see if they are losing any material.

“In almost 10 years, we have hardly lost any tubes and have had minimal issues with the Rentech HRSG,” said Cutshaw. “The key to smooth HRSG operation is to have a good HRSG from a reliable vendor and then make sure that water treatment is done well so water quality remains very high.”

A visual inspection of the HRSG is done every outage to check the diverter, make sure there are no hot spots, and that there is no loss of insulation. The plant manager noted that tubes on the HRSG have held up well despite 10 years of constant use. He is not seeing degradation of the tubing, which he puts down to good manufacturing and extremely clean 900-class feedwater.

The boiler itself was intentionally oversized. Most of the time it runs at 75,000 lbs per hour though the HRSG is capable of operating at 200,000 lbs per hour when the duct burners operate. “It is best to oversize the HRSG as you run into fewer maintenance issues and have the option of adding more steam if you need it,” said Cutshaw.

Despite being oversized, the HRSG could still be built and assembled in the Abilene, Texas, facility of Rentech and shipped to Eight Flags in a couple of large modules. Any larger, and the facility might have had to specify a stick-built unit, which would have added to costs, introduced onsite construction complexity, and increased the timeline.

Waste heat is used in the HRSG to make steam, but the heat left over is harnessed by using an economizer to heat feedwater for the boiler and demineralized water for RYAM. Effective use of waste hear raises overall efficiency at Eight Flags to 80%.

Hydrogen Combustion Plans

Many facilities are looking for ways to reduce emissions. At Eight Flags, initial testing with hydrogen has already taken place. The Solar Titan 250E at Eight Flags can burn up to 5% hydrogen by volume. To increase that amount, the facility would need to upgrade the fuel injectors in the combustor.

Eight Flags has run two successful hydrogen tests at up to 5% hydrogen. This included stack testing to ensure emissions levels remained compliant. Testing found that emissions levels dropped using this small amount of hydrogen. There was a noticeable difference in emissions due to the cleaner burning qualities of hydrogen. There was also a slight improvement in turbine power output, according to the plant manager.

Management is exploring various options for the incorporation of green hydrogen burning at Eight Flags. For example, there is a green hydrogen site in Kingsland, Georgia. It might be feasible to truck in green hydrogen from that site. Alternatively, some companies are using solar power to provide power to electrolyzers that would then produce green hydrogen. The company is looking at different ways to introduce more hydrogen into the natural gas combustion at Eight Flags.

—Drew Robb (drewrobb@sbcglobal.net) has been a full-time freelance writer for more than 25 years specializing in engineering and technology.