Advanced analytics solutions empower utilities to predict asset failures before they happen so they can progress from reactive to proactive maintenance.

As the digital transformation of the power industry continues to evolve, organizations are placing more focus on managing costs, improving grid operations, and expanding market opportunities. But due to a lack of accessible data, and thus an inability to analyze and use that data to improve operational outcomes, adoption of digital initiatives has been limited.

At the same time, the power industry is under pressure to modernize systems to meet customer needs, comply with regulations, and achieve better operational performance. Proper asset management is a key factor in meeting these demands, and effectively managing maintenance at scale requires software that can keep pace with the growing volumes of operational and maintenance data.

Without established asset management models and equipment maintenance programs, electric utilities can incur unexpected and costly repairs and fines for unplanned outages. Fortunately, with innovative advanced analytics applications, access to data and the delivery of insights can be provided efficiently—empowering organizations to leverage operational data for informed decision making to determine ideal times for repairs, replacements, or retrofits.

Spreadsheets Are Inadequate

Although electric utilities have embraced automated solutions, including supervisory control and data acquisition systems, to improve operations and ensure key performance indicators are met, the effective management of assets remains a leading challenge. Without a data-based asset maintenance program in place, teams are forced to use a reactive approach to asset failures, making it easy to fall behind on maintenance. While manually tracking an asset from installation to repair or replacement is an option, these manual procedures, in addition to static or offline reporting and data formatting incompatibilities, often create issues.

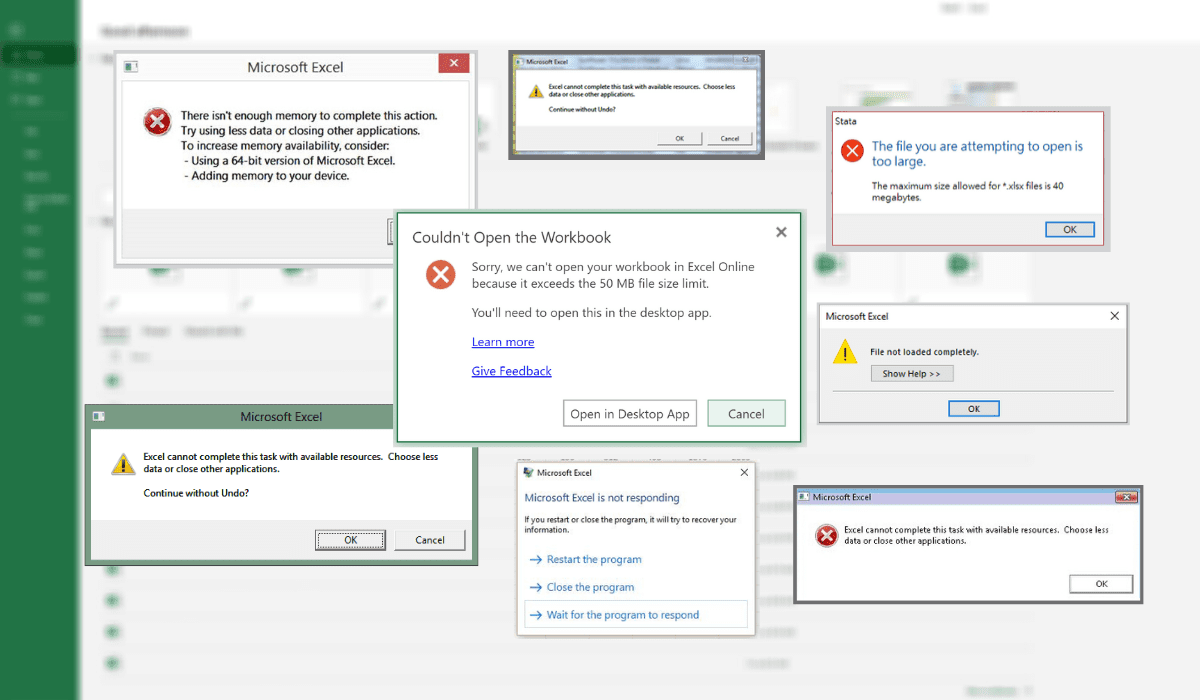

With a lack of access to operational data, subject matter experts (SMEs) face seemingly insurmountable hurdles, often spending days or even weeks conditioning, verifying, and contextualizing data using manual, spreadsheet methods. Although spreadsheets have long been the standard method for analyzing data within the power sector, this type of general-purpose tool is not agile enough to define relevant context quickly.

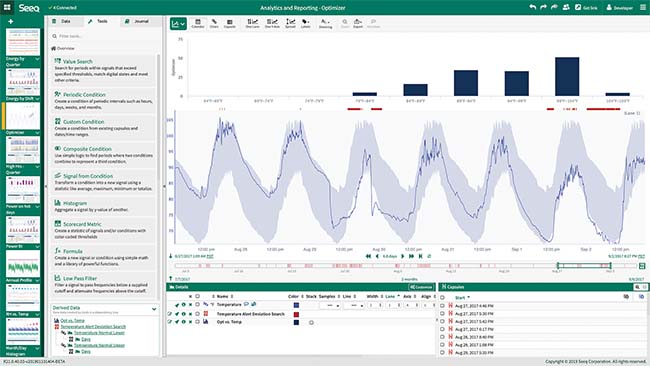

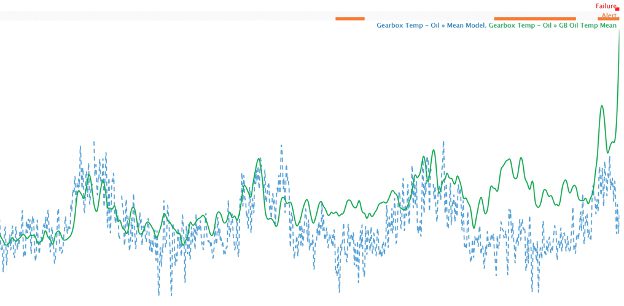

Additionally, it is difficult for SMEs to apply and share specific operational knowledge. Adjustments for non-uniform intervals of data are very complex, as are making corrections for inaccurate dates, outliers, and missing or corrupt data. Lastly, spreadsheets require strict protection against user corruption and version management, resulting in limited multiuser collaboration. As data volumes grow, in both granularity and complexity, these challenges become more serious, ultimately requiring a more robust solution (Figure 1).

|

|

1. Spreadsheets cannot handle the increased volumes of data that must be analyzed to provide effective asset management. Courtesy: Seeq |

As systems grow and inexpensive connected sensors become more readily available and widely deployed, asset management strategies require scalable and agile advanced analytics solutions that can access that data, regardless of where it resides. These solutions enable teams to uncover diagnostic, performance, condition monitoring, and asset forecasting insights, while providing the information required for data-driven decisions and optimization.

Advanced Analytics Applications Address Issues

Digital transformation is an ongoing process that requires investments in analytical skills and new software applications. Engineers, SMEs, and data scientists must be able to interact directly with time series operational data to not only execute data cleansing and contextualization tasks, but to also quickly create models, leading to increased reliability and uptime.

Advanced analytics applications provide a comprehensive solution for developing and managing predictive models, even when input parameters are from multiple and disparate data storage systems. These types of applications connect to existing data historians and databases, both on premises and cloud-based, without copying or duplicating the data from source systems. By leveraging automated cleansing and easy-to-implement calculations and data contextualization, SMEs can quickly perform diagnostic, predictive, and descriptive analytics on time series operational data.

Analyses can be complicated by noisy data, including erroneous values and spikes. Advanced analytics applications enable SMEs to eliminate or reduce this noise using automated cleansing methods, such as smoothing filters, providing simpler contextualization. They can also leverage time shifting and outlier removal methods, which ignore irrelevant data, such as when an asset is not in operation or is in startup mode. These tools enable SMEs to eliminate wasted time sorting through spreadsheets and manually wrangling data, providing them with greater opportunities to analyze patterns and develop models leading to transformational insights.

Data scientists are also key players in driving digital transformation as they are tasked with creating new ways to maximize operational efficiencies and predict future states. Accurate forecasting is critical for utilities as their portfolios are expanding to include renewables and distributed energy resources. Data scientists can use data from these sources to create models that more accurately determine when energy will be needed, taking external factors into account for these forecasts. They can then collaborate within the advanced analytics applications with SMEs to ensure the integrity and relevance of the data being modeled, and to provide optimal outcomes.

These models can also be applied to grid connected assets to analyze and identify equipment headed for failure, empowering teams to plan and budget for repairs, while avoiding costly unexpected outages. By enabling SMEs to focus on analytics rather than data wrangling, advanced analytics solutions play a crucial role in an SME’s ability to quickly determine the root cause of an asset failure.

Similarly, these applications play an important role in the predictive and pattern recognition analytics required for SMEs to progress from reactive or time-based maintenance schedules to data-based decision making, avoiding costly unplanned downtime. Models developed by a SME on one asset can then easily be scaled to all other applicable assets, allowing for streamlined predictive asset management at scale.

Advanced analytics applications also provide enhanced real-time collaboration capabilities, enabling greater visibility across teams by accelerating the communication of insights across the broader organization. As the power industry examines the case for modernizing analytical practices, these collaborative methods are critical to success because streamlined knowledge sharing enables improved maintenance programs, business processes, and operational production efficiency.

Positive Results

Electric utilities are embracing new advanced analytics technologies to take full advantage of their growing data volumes by solving increasingly complex asset management use cases.

Variable Renewable Energy Asset Maintenance Forecasting. As generation portfolios increasingly consist of variable renewable energy (VRE) assets, ensuring maximum uptime is of ever-increasing importance. The ability to detect a failure well before it happens typically results in a much less costly repair to the asset. This type of proactive maintenance also provides the ability to better plan VRE asset capacity, reducing complexity in management and generation forecasting of these inherently variable assets.

Predictive maintenance for VRE assets was examined by a major North American power generator for managing many wind turbines that had experienced several failures. These issues resulted in a loss of generation capacity, along with elevated maintenance expenses as compared to proactive maintenance. This electric utility selected Seeq, an advanced analytics application, to unify alarms, maintenance, and operational data—and to create an online health indication for their fleet of wind turbines.

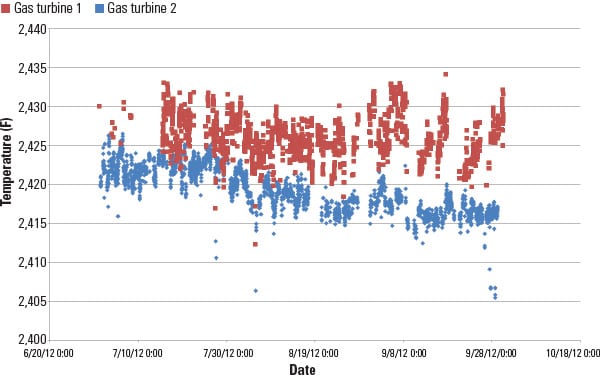

Leveraging the suite of point and click tools to cleanse data, SMEs can now easily cleanse lengthy periods of operational data for wind turbines, then identify a period when each turbine was operating optimally. With the now contextualized data unified with maintenance and alarm logs, the SMEs leverage predictive analytics in Seeq to develop regression-based models of turbine operation. These models, combined with SME expertise, are used to identify when each wind turbine begins to deviate from the modeled state, indicating a failure as verified by past failures (Figure 2).

|

|

2. A turbine gearbox oil temperature signal compared to a modeled value, with a deviation threshold leading up to a failure event indicated. Courtesy: Seeq |

Utilizing an asset hierarchy created with the advanced analytics application, this same modeling methodology was easily scaled out to the fleet of turbines by the SMEs. The maintenance department is now able to take a wind turbine out of service prior to a complete failure, thereby greatly reducing the cost of maintenance, while enabling improved planning, for example, by scheduling maintenance during periods of low power demand.

Determining True Transformer Age. Deciding when to replace a substation power transformer is a challenging task because it is difficult to identify when it has reached the end of its useful life. While most transformer manufacturers define the end of life as age 40, lightly loaded transformers may not reach the true age of 40 until their 60th or 70th year in service, while heavily loaded transformers may age prematurely.

Without the right tools for trend analysis, the effects of loading beyond a transformer’s nameplate rating are extremely difficult to calculate over time. This makes it challenging to determine a transformer’s true age, and as a result, many transformers are run to failure, resulting in high-risk operating scenarios and costly response efforts. Alternately, lightly loaded transformers may be replaced prematurely, increasing expenses.

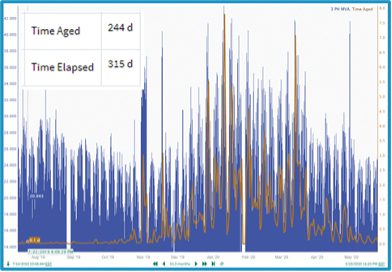

Seeking a solution to this challenge, one electric utility sought to identify the true age of its transformers by using the IEEE C57.91-2011 standard, a loss of life algorithm. By leveraging Seeq, it combined temperature and loading data from real-time data historians with nameplate data stored in SQL to calculate the true age of their transformers. Through rapid iteration and refinement of analysis across assets, utility personnel were able to identify which transformers were at the highest risk based on true-age calculations (Figure 3).

|

|

3. The scorecard illustrates calculated age versus elapsed time, along with loading trend and calculated age. Courtesy: Seeq |

As a result, the utility reduced capital expenditures by prioritizing replacement based on actual equipment age, while improving system reliability to avoid millions of dollars in downtime and capital expenditures for premature replacement.

Modernize Your Asset Management Approach

Electric utilities are under increasing pressure to provide not only reliable and low-cost power, but to do so in an environmentally responsible way. Advanced analytics applications can help utilities manage the assets in their entire power generation portfolio more efficiently and effectively. This increases uptime, while greatly reducing the cost of maintenance because issues are addressed proactively instead of reactively. The ability to schedule maintenance strategically is particularly important for electric utilities because power demand fluctuates widely from hour to hour, and from season to season, providing windows for service.

The right advanced analytics application provides personnel with the tools they need to quickly create insights, scale results across the organization, and share knowledge with other team members. This enables creation of an effective asset management strategy to improve operations, while increasing personnel productivity.

—Sean Tropsa is a senior analytics engineer at Seeq.