Without a doubt, the future for bucket trucks is bright, with significant growth projected for the category partially as a result of the extensive infrastructure upgrade programs that have been…

Without a doubt, the future for bucket trucks is bright, with significant growth projected for the category partially as a result of the extensive infrastructure upgrade programs that have been…

For maximum efficiency and operational flexibility, advanced gas turbines have rightly been optimized to the nth degree. However, there are big opportunities in important related components like the air inlet…

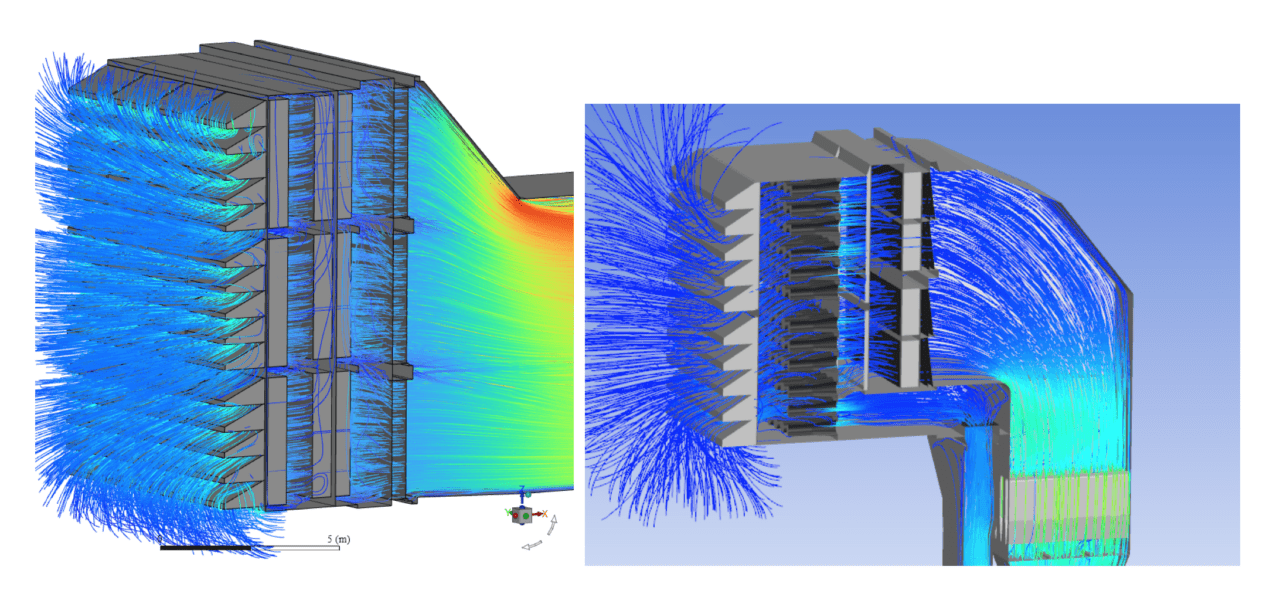

Gas turbines require high-quality air to operate reliably. However, increasing temperatures and reduced rainfall are increasing the frequency of dust storms in many parts of the world. In these circumstances,…

OVERLAND PARK, Kan., February 03, 2022 - The Gas Turbine Filtration Division of Parker Hannifin Corporation, the global leader in motion and control technologies, has released new ancillary spares kits…

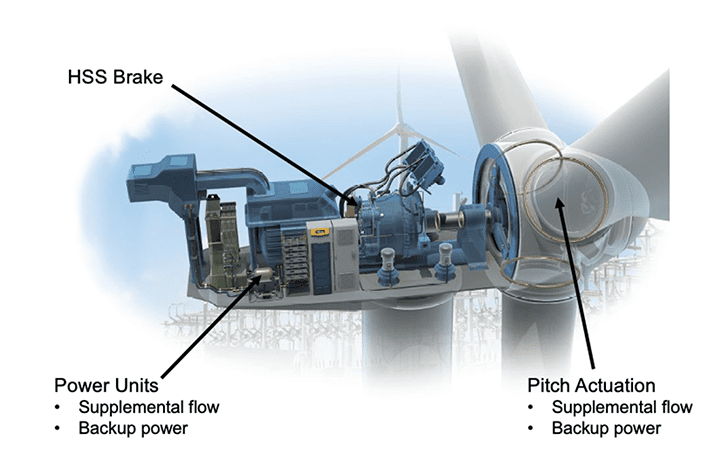

Wind turbines are designed to maximize power production based on the predicted wind speeds found at the plant site. However, excessive wind speeds are experienced at times, so it is…

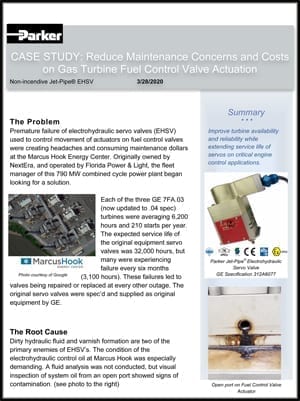

Electrohydraulic servo valves (EHSVs) have been used for precise control of hydraulic actuators since the 1940’s. Taking an electrical control voltage and converting this into a hydraulic flow response enables […]

Duke Energy announced the completion of a 2-MW battery-based energy storage system that has been installed to increase power grid reliability and stability for the PJM regional transmission organization. Installed…

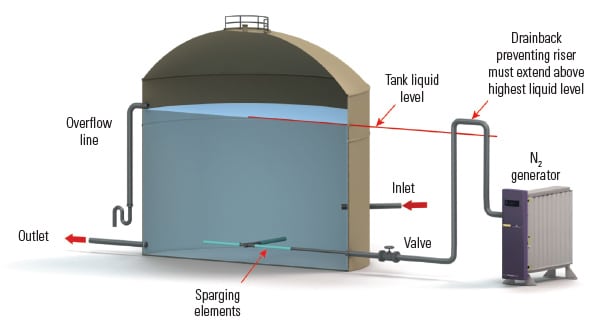

The electric power generation industry relies heavily on demineralized and deionized water during process operations. Managing the water supply is critical not only under normal operating conditions, but also during…