operations and maintenance

-

Press Releases

PIDC Awards Dominion Energy the Electric Utility Operations & Maintenance Contract for the Philadelphia Navy Yard

Philadelphia, Pa. (May 19, 2021) — PIDC, Philadelphia’s public-private economic development corporation and master developer of the Philadelphia Navy Yard, announces the award for a 10-year electric utility Operations and Maintenance (O&M) services contract to Dominion Energy for the Navy Yard following a highly competitive solicitation process. This contract will go into effect on November […]

-

Nuclear

Advanced Technology, Innovative Solutions Enhance Nuclear Operations and Maintenance

Incorporating new technology and solutions being used by others could help nuclear power plant staff improve operations and maintenance practices. Nuclear power plants face many challenges. Monitoring heat

-

Coal

Fending Off Forced Power Plant Outages

The changing profile of the power system has added new stressors on conventional power generation and may have raised the potential for forced outages. Addressing them requires a closer look at traditional and

-

News

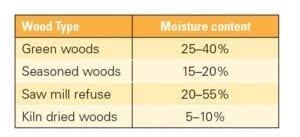

How to Avoid Full Refractory System Failure in Wood Combustion

Wood-burning facilities have seen a spike in refractory problems due to operating units at higher temperatures and at increased capacities than in the past. Refractory professionals offer three recommendations

Tagged in: -

O&M

Virtual Switchgear Walk-Through Creates Maintenance Advantage

An Industrial Internet of Things (IIoT) revolution is happening across essential power systems, and it’s helping make the challenges of maintenance walk-throughs a problem of the past. With more data and

Tagged in: -

O&M

Advantages of AI-Powered Asset Management for Utilities

Artificial intelligence (AI) and machine learning have become major factors in nearly every industry, and have increasingly become more popular among utilities. Automated technology is being used to inspect

-

O&M

Finding a Security Solution for a Control Room

Control rooms are the nerve center of any power plant. Two recent control room upgrades at U.S. facilities highlight the logistical challenges and solutions to issues that come with improving an important

Tagged in: -

Connected Plant

Using AI-Powered Thermal Tagging to Prevent Summer Overheating Outages

Summertime heat is cresting at the same time many economic restrictions related to the COVID-19 pandemic are easing in communities across the United States. Meanwhile, as extreme weather events are becoming more frequent, much of the country is on alert as forecasters predict severe hurricane, tornado, and wildfire seasons will continue. Utilities know they need […]

Tagged in: -

O&M

Changes in Boiler Operations Bring Innovations in Erosion and Corrosion Protection

Metal loss of the pressurized tubes inside the boiler is a big concern for boiler designers and operators. Changing fuel composition and other service parameters can lead to accelerated erosion and corrosion

-

O&M

Keeping Track of O&M Costs and Processes in the Field

Cost. The dirtiest word in clean energy—especially with operations and maintenance (O&M) costs set to rise globally to $17 billion in 2020 in the wind industry. Part of saving on O&M costs means taking a look at the inefficient processes that skilled workers are doing as part of O&M procedures to optimize their time. A […]

Tagged in: