MD&A

-

Gas

The Clock Is Ticking on 7FA Gas Turbine Rotors

Operators of aging F-class units face a narrowing window to plan for rotor life extensions as supply chains tighten and demand surges. The late 1990s and early 2000s marked a frenetic period in American power generation. Deregulation opened the floodgates for independent power producers racing to bring quick-build gas turbine plants online. GE’s 7FA and […]

-

Partner Content

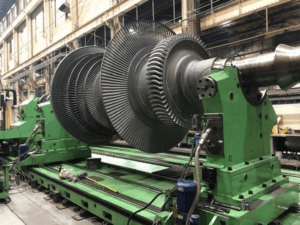

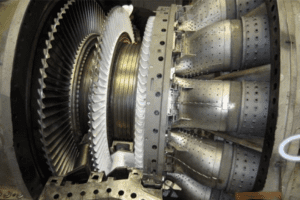

Full-Service Steam Turbine Major

Sponsored by:

MD&A performed a Full-Service Steam Turbine Major outage, which included the HP/IP inspection and repairs on a 610MW GE® G2 steam turbine. While keeping tight to the schedule deadline, several of MD&A’s divisions and teams worked closely together on this comprehensive engagement, both onsite and offsite. They performed an extensive scope of work ranging from […]

-

Partner Content

MD&A Generator Stator Rewind with Timely New Bars

Sponsored by:

Time and time again, Mechanical Dynamics & Analysis (MD&A) shows the global utility industry its strength, technical capability, and resource depth to serve as a premier alternative to the original equipment manufacturer for both services and parts supply. In fact, MD&A established itself in the beginning as the preferred non-OEM supplier, regardless of original supply […]

-

Partner Content

Back-to-Back Major Overhauls on Two 7F.04 Gas Turbines and 7FH2 Generators

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) has completed back-to-back major inspections of two 180-MW GE® 7FA.04 gas turbines and 7FH2 generators, returning both to fully dispatchable service on schedule. The complexity of the planning & implementation of these outages for the owner/operator exemplifies the time-proven expertise and capabilities that exists throughout MD&A. MD&A provided all project […]

-

Partner Content

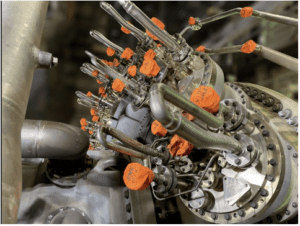

Main Stop Control Valve and Bucket Replacements

Sponsored by:

MD&A performed a major inspection and scheduled repairs of a Toshiba® 130 MW steam turbine. During this planned outage, along with a LP turbine inspection, the combined main stop/control valve (MSV/CV) was replaced, as well as the L-0 and L-1 buckets. MSV/CV Replacement Replacement of the combined main stop / control valve (MSV/CV) was requested […]

-

Partner Content

7EA Turbine Major & 7A6 Generator Minor Inspection

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) performed a GE® Frame 7EA Gas Turbine Major inspection and a 7A6 air cooled Generator Minor inspection including planned maintenance for a peaking unit in the Midwest. The planned scope of work included replacement of combustion and hot gas path (HGP) hardware and components, IGV gears, ring gear, and bushings. […]

-

Partner Content

7A6 Generator Isomode Pad Replacement with Major and Rewind

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) has completed another successful generator rewind as part of life extensions programs on a gas turbine fleet in the northwest US. This project featured a unique focus on the totally enclosed water-to-air cooled (TEWAC) assembly including complete GE® 7A6 generator isomode pad replacement. MD&A provided all tooling, supervision, and labor […]

-

O&M

Turbine MRO Best Practices: Expert Guide to Maintenance, Repair, and Overhaul

Effective maintenance, repair, and overhaul (MRO) practices are vital for reliable turbine operation. Innovative technologies such as artificial intelligence and 3D scanning are transforming MRO processes

-

Partner Content

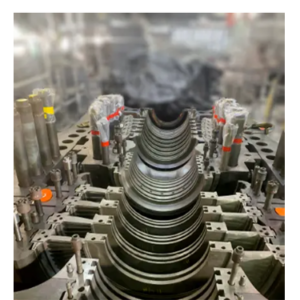

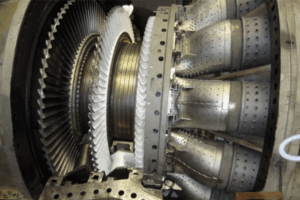

Gas Turbine Compressor Rotor Blade Re-staking in the UK

Sponsored by:

When an overseas steam-side client asks you back to manage a gas turbine project, that confirms confidence in your project leadership, full-scope knowledge, and technical depth. Mechanical Dynamics & Analysis (MD&A) is a GE® 9FA turbine full-service provider. MD&A was contracted to manage and apply their hands-on skills to disassemble, inspect, re-stake, and reassemble a […]

-

Partner Content

Excitation Controls Retrofit

MD&A’s Turbine and Generator Controls Division recently completed turnkey installation services for an excitation system retrofit at a power generation plant. The project entailed the replacement of several key components including the voltage regulator and interface to the control and protection systems. The team handled the entire project including design, component selection, installation, and unit […]

-

Workforce

Effective Training and Mentoring Programs Are Critical to Power Project Success

The power industry has long been lamenting its aging workforce. While turnover has been happening for years, there remains a large percentage of power professionals on the verge of retirement. Furthermore, the U.S. Bureau of Labor Statistics predicts faster than average job growth for engineering occupations. That means experienced workers with the skills needed by […]

-

Partner Content

7FH2 Partial Re-Stack of the Core Step Iron & Full Stator Rewind

Mechanical Dynamics & Analysis performed a 7FH2 Partial Re-Stack of the core step iron & Full Stator Rewind on a GE® 7FH2 generator. Several 7FH2 units have experienced failures of the core step iron, caused by inadequate compression of the core laminations. This issue was first brought to light by GE® TIL 2260, which only […]

-

Partner Content

7FA.04 (AGP) Gas Turbine Component Repairs – Enhancing Performance and Cost Savings

Sponsored by:MD&AMechanical Dynamics & Analysis (MD&A) is a leading provider of gas turbine component repairs. With a focus on maintaining optimal performance and reducing operating costs for our customers. MD&A has developed a range of repair processes for 7FA.04 advanced gas path (AGP) components. Significant savings can be realized by opting for lower-cost repaired spares instead […]

-

Partner Content

Tackling Emerging Issues with 7FA Compressor Blade & Vane Replacement

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) completed compressor blade replacement work on two 7FA units, including full inspections, and ongoing operational recommendations. We were responsive to emerging issues, scope change and flexible in supporting the customer’s needs. MD&A was mobilized to address suspected fuel nozzle leaks on the customer’s unit 1 gas turbine. The unit had been shut down […]

-

Partner Content

Recommissioning Legacy Turbine Control Systems for Enhanced Reliability

Sponsored by:

Increases in renewable energy on the power grid have increased the need for reliable peaking power. In many cases, these assets are available but less reliable than they once were due to the age and neglect of their control systems. In most cases, refurbishment of digital systems from the last 30 years is a viable […]

-

Partner Content

Coordinated 7FA Hot Gas Path and 7FH2 Generator Inspection and Repair

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) completed a carefully coordinated 7FA gas turbine hot gas path inspection, 7FH2 generator inspection and repairs in just 19 days, providing all services, labor, and parts. The customer contracted MD&A to perform the inspection and emergent repairs on a tight schedule. Our industry experts completed the work on time maintaining full customer communication […]

-

Partner Content

Portable In-Situ Air Flow Test Stand – Oct. 2021

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) announces Portable In-Situ Air Flow Test stand capabilities that allow for immediate and conclusive data on gas turbine nozzle performance. This flow test apparatus provides efficient gas turbine air/gas flow analysis and is offered by MD&A Fuel Nozzle Services Division/ Integrated Combustion Solutions (ICS). The typical call to action is a control room combustion […]

-

Partner Content

Combined Cycle Overhaul with our One-Stop Shop – Sept. 2021

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) recently completed an overhaul at a combined cycle plant consisting of gas and steam turbine majors, a steam turbine generator minor inspection, and a gas turbine generator major inspection. The customer combined scope was the largest single project implemented at the site since the combined cycle plant was commissioned. MD&A sent all 3 rotors from […]

-

Partner Content

Co-Gen Turbine Controls Retrofit – Nov. 2021

Sponsored by:

Mechanical Dynamics & Analysis’ Control Systems Division (MD&A Control Systems) replaced an industrial co-gen turbine’s original mechanical-hydraulic (MHC) controls with an electronic governor, electro-hydraulic trip system and self-contained control valve actuator. The primary drivers for the project were the operator’s desire to increase the long-term maintainability and reliability by replacing the MHC components that had […]

-

Partner Content

Global Multiyear Major Outages

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) recently performed multiyear outages for a customer on several different units in Colombia. First unit: This was a major outage and generator test & inspection. In addition, this unit was retrofitted with a new rotor, bearings, and steam path components that required machining, including installing and fitting new nozzles. MD&A […]

-

Partner Content

Frame 5 Gas Turbine Rotor Repair

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) repaired a Frame 5 gas turbine rotor. MD&A replaced 1st and 2nd stage buckets, repaired the seal area on the row 1 turbine wheel, performed compressor blade blending, and machined the thrust collar to accommodate the newer style thrust bearing at the No. 1 bearing. During their planned major inspection, the […]

-

Partner Content

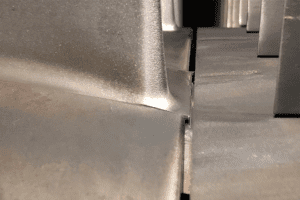

Casing/ Shell Weld Repairs & Re-Rounding

Sponsored by:

For many years, the OEM fix for major cracking or shell distortion was replacement of the defective shell, also referred to as casing by some OEMs, with new. Mechanical Dynamics and Analysis has provided an alternative to shell replacements which includes fixing the existing shell to extend its life. MD&A recently welded and repaired the HPIP […]

-

Partner Content

Field Rewind with a Rotor Slot Dovetail Repair

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) recently completed generator field rewind with a rotor slot dovetail repair on a customer’s GE® 650,000 KVA generator field. The work scope was performed at the customer’s direction with regards to applicable Technical Information Letters. Incoming visual and mechanical inspections were first completed, as well as a runout inspection in the lathe which […]

-

Partner Content

Steam Turbine Rotor Straightening in Abu Dhabi

Steam turbine work on the international stage can have its challenges, but also its successes. Mechanical Dynamics & Analysis (MD&A) was contracted to inspect, analyze, and then straighten a Toshiba® steam turbine rotor in Abu Dhabi, United Arab Emirates. MD&A launched its team into action for a full analysis of the issues followed by a resolution of […]

-

Webinar

Steam Path Audit

Sponsored by:

MD&A’s Steam Path Audit webinar describes the technical process of conducting a visual inspection of a steam turbine’s steam path for the purpose of identifying and quantifying deficiencies in thermal efficiency. The results of the inspection are used to determine the root cause of efficiency degradation and to guide maintenance during an outage such that […]

-

Gas

Life Time Extension of Gas Turbines Components

Sponsored by:

In this webinar we will cover the typical limiting factors of gas turbine components and how they can be repaired. We will cover the steps used in implementing a life time extension and will show some case studies. Some examples of how new parts are redesigned with features that make them more robust will also be covered.

This webinar will be beneficial to the engineers and power plant personnel involved with the refurbishment and replacement of the gas turbine hot gas path components.

-

Partner Content

How to Extend the Lifetime of Gas Turbine Parts

Sponsored by:

Elevated temperatures take a big toll on gas turbine components risking cracks, corrosion, wall thickness, and material condition. Repair enhancements can extend a part’s life by slowing its degradation and pushing out its usable service life. Operators can see significant savings by opting for lower-cost repaired spares instead of new parts as demonstrated in the following case studies.

-

Partner Content

Behind the Scenes: Turbine and Generator Inspection and Repair in 19 Days

Sponsored by:

The countdown was set for T-19 days to complete a 7FA gas turbine hot gas path inspection together with a 7FH2 generator inspection and repairs providing all services, labor, and parts. While the average time for such project can be much higher, the Mechanical Dynamics & Analysis (MD&A) team of experts was able to perform a carefully

-

Gas

Test Your Knowledge: Competitive Maintenance Strategies

Competitive maintenance uses an analytical process and condition-monitoring tools to select the optimum maintenance strategy for each plant system. For example, the optimum strategy for the plant’s steam turbine will be different than that for its gas turbine, and vastly different than that of its feedwater pumps. How well do you know your maintenance strategies? […]

-

Partner Content

MD&A IBECS® – The Integrated Solution to Power Plant Control and Monitoring

Sponsored by:

Power plant control and monitoring can be complex given the need to integrate many different platforms. Adding to the complexity is the fact that HMI’s (Human-Machine Interface) supplied by the OEM often only interface with the OEMs controller and not with ancillary systems. Lastly, ongoing support and updates from the common operating system may be […]