Sweden has broken ground on its final repository for spent nuclear fuel (SNF)—a milestone reached after 40 years of research and development—making it the world’s second deep geological repository (DGR) now under construction.

Svensk Kärnbränslehantering AB (SKB), a nuclear fuel and waste management company owned by Sweden’s nuclear operators, officially announced the start of construction for the DGR at Forsmark, Östhammar Municipality, near Vattenfall’s 3.2-GW Forsmark nuclear power plant, on Jan. 15. The milestone kicks off a 10-year construction period for the Swedish Spent Fuel Repository. “The final repository will be ready for disposal in the 2030s and will be fully extended in the 2080s,” the company noted.

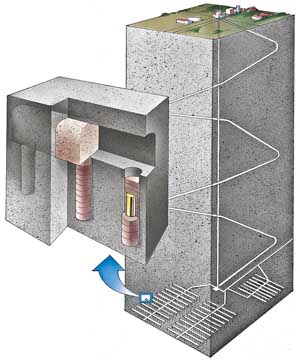

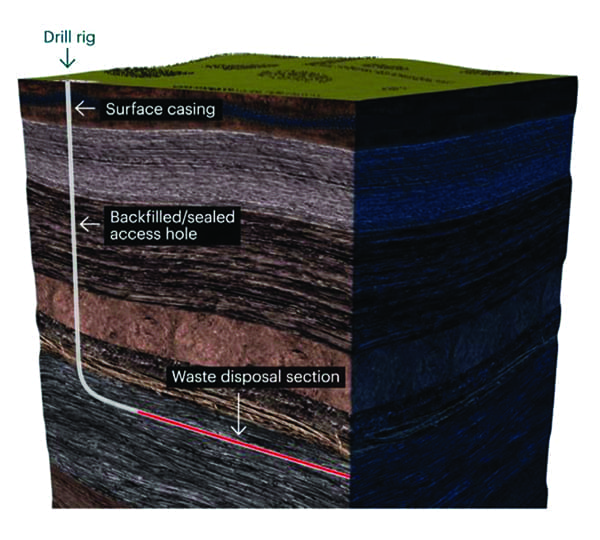

The final repository is envisioned as a vast underground project that will bore 500 meters deep in rock that is 1.9 billion years old. When completed, it will store 12,000 tonnes of SNF in 6,000 copper canisters, shielded by bentonite and placed along 60 kilometers of tunnels. The surface section will cover a total area of 24 hectares—“the equivalent of 44 soccer fields,” SKB said.

Groundbreaking involves “the start of two years of preparatory work above ground, including the construction of a rock mass storage and water treatment plant, a bridge over the cooling water canal and forest clearing,” SKB said. “After that, work begins to go down into the bedrock.”

A Milestone 40 Years in the Making

The milestone is a major triumph for SKB, which is owned 36% by Vattenfall AB, 30% by Forsmarks Kraftgrupp AB, 22% by OKG Aktiebolag, and 12% by Sydkraft Nuclear Power AB. The company was founded after research initiated by the Swedish government regarding the handling and final disposal of radioactive waste started on a large scale in 1975. The nation intensified its research through the industry-led Nuclear Power Safety (KBS) project, leading to the use of the KBS-1 and KBS-2 methods, and eventually, in 1980, the KBS-3 method, which emphasized the use of DGRs within crystalline bedrock for the long-term containment of SNF.

In 1992, a site selection process was initiated via a voluntary response approach. In 2009, after five years of site investigations, SKB selected Forsmark, submitting a license application for the proposed site and the KBS-3 containment method to the government in 2011. More notable milestones came in January 2018 and October 2020, when the municipalities of Oskarshamn and Östhammar voted to approve the repository. In January 2022, Sweden’s government gave SKB the green light to proceed with the DGR

Swedish nuclear operators have remained consistently supportive of the project, warning that interim storage capacity will not be adequate in the long run. Sweden’s nuclear fleet currently includes six operating reactors, which generate nearly 30% of the country’s power with a combined capacity of 7 GW. State-owned utility Vattenfall co-owns five units, including Forsmark 1, 2, and 3, and Ringhals 3 and 4, while Oskarshamns Kraftgrupp (OKG) owns the sixth, Oskarshamn-3.

Following a landmark change in its energy policy in June 2023—from a target of 100% renewable electricity by 2040 to 100% fossil-free electricity—the Swedish government announced an ambitious roadmap for nuclear power. By 2035, Sweden plans to construct two large-scale reactors, each with a capacity of 1,250 MWe. Beyond this, the government aims to deploy the equivalent of ten additional reactors, including small modular reactors (SMRs), by 2045. Key projects include Vattenfall’s plans to build new capacity at Ringhals, with deployment expected in the early 2030s, and feasibility studies for SMRs at both Ringhals and Oskarshamn, spearheaded by Vattenfall, Fortum, and other partners.

The renewed focus on nuclear energy is supported by legislative changes, which have moved to remove a cap on the total number of reactors and expand allowable construction sites beyond existing nuclear facilities. “The background to this reversal can be explained by increasing climate awareness, a cumbersome geopolitical situation, increased technical challenges related to the electricity system, and a more strained national economy where its link to the electricity price has become increasingly clear,” a recent report from the national nuclear coordinator reads.

Sweden’s nuclear plants rely on the CLAB repository near Oskarshamn as their sole interim storage facility for spent nuclear fuel. Operational since 1985, CLAB stores used fuel underwater in a granite cavern to allow for cooling and reduction of radioactivity. Originally designed for 5,000 tonnes, its capacity has been expanded to 11,000 tonnes to accommodate all fuel from Sweden’s reactors. Spent fuel remains in CLAB for 40–50 years before being encapsulated in copper canisters for final disposal in the planned Forsmark repository.

Finland’s DGR Nearing Completion

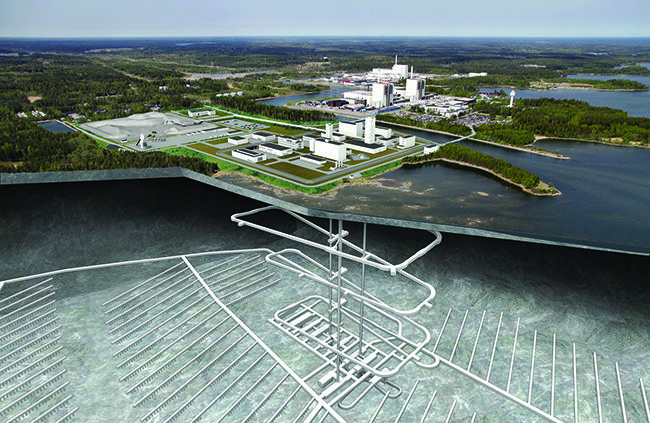

Sweden’s progress closely mirrors Finland’s, where the world’s first DGR is nearing completion, spearheaded by Posiva. Construction of the Onkalo repository, which began in 2004, has so far included the development of a 430-meter-deep storage system within crystalline bedrock, featuring spiral-shaped access tunnels, vertical shafts, and encapsulation facilities. In a trial run launched in September 2024, Posiva successfully encapsulated and stored three canisters filled with non-radioactive test elements.

The trial aims to validate the entire disposal process, including encapsulation, transportation, and final emplacement in bedrock. If all goes according to plan, full-scale disposal operations could be ready to begin within the next two years. In December 2024, however, Finland’s Radiation and Nuclear Safety Authority (STUK) delayed its safety assessment of Posiva’s operating license for the above-ground encapsulation plant and final disposal facilities by a year, citing incomplete materials and updated technical plans from Posiva. STUK now expects to deliver its safety statement by Dec. 31, 2025.

Finland and Sweden’s projects, notably, benefit from a collaborative approach. Like the Forsmark project, the Onkalo project will use SKB’s KBS-3 repository method. In December, SKB announced an agreement with Posiva to weld the bases of canisters for Finland’s final repository for spent nuclear fuel. The work, scheduled to begin in 2025, will be carried out at SKB’s Canister Laboratory in Oskarshamn, leveraging advanced friction stir welding technology.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).