Focus on O&M

-

O&M

Abrasion-Resistant Pipe Handles Ash Slurry

Steel piping systems are widely used at coal-fired power plants for a variety of purposes, including the conveying of coal ash slurry to nearby settling ponds, the transfer of limestone slurry to absorber spray towers for removal of SO2 and dilute hydrochloric acid from flue gases, and for transporting away the calcium sulfate by-product of the flue gas desulfurization process.

-

O&M

Air Casters Speed Equipment Moves

When it comes to moving megaton items like feedwater heaters or recirculating pumps, conventional moving tools such as wheel rollers, cranes, hoists, and come-alongs may be virtually useless. In some cases, moving large components is dangerous in a space-constrained location surrounded by delicate process control equipment. Feedwater heater and recirculating pump removal and replacement are […]

-

Nuclear

NRC Confident in Long-Term Dry Cask Storage

The U.S. Nuclear Regulatory Commission (NRC) approved an updated “waste confidence” rule in mid-September that reflects the agency’s confidence that spent nuclear fuel (SNF) can be safely stored for at least 60 years beyond the closing date of any U.S. nuclear plant. Approval of this rule was required before the NRC can license any new reactors that will be required to store SNF on site indefinitely.

-

Nuclear

EPRI Updates Spent Nuclear Fuel Storage Handbook

EPRI recently issued a handbook on nuclear spent fuel storage that examines regulatory trends affecting used fuel storage, describes available dry storage technologies, reviews planning considerations for spent fuel storage installations, and discusses technical issues affecting dry storage.

-

Business

Lessons Learned in Reliability Standards Compliance

It has been three years and a few months since the North American Electric Reliability Council (NERC) Reliability Standards (Standards) became mandatory and noncompliance became subject to sanctions by the Federal Energy Regulatory Commission (FERC). You might assume that because we have had no further instances of widespread cascading outages that the Standards are working. You may also assume that—considering the database of documented noncompliance with the Standards—the industry as a whole is puzzled, unprepared, or negligent in carrying out its responsibility to keep the high-voltage electric grids reliable and secure. The truth likely lies somewhere in the middle.

-

Smart Grid

Smart Grid Cyber Security Guidelines Released

The National Institute of Standards and Technology (NIST) has finalized its initial set of smart grid cyber security guidelines. NIST’s Guidelines for Smart Grid Cyber Security (NISTIR 7628) includes high-level security requirements, a framework for assessing risks, an evaluation of privacy issues in personal residences, and other information for organizations to use as they craft strategies to protect the modernizing power grid from attacks, malicious code, cascading errors, and other threats, according to NIST’s press release.

-

O&M

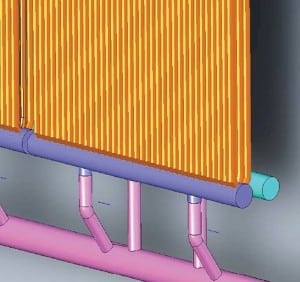

Innovative Cleaning of Air Preheater Coils with Pressurized Liquid Nitrogen

Cleaning air heaters in power plants or recovery boilers has traditionally involved using high-pressure water, chemicals, or steam. These techniques, though effective on moderate airside fouling of heat exchange surfaces, are usually ineffective on the more tenacious deposits that can develop in coal-fired plants. If these deposits are not removed by periodic cleaning, heat transfer in the heaters is reduced, which in turn reduces boiler efficiency and increases a unit’s heat rate. Severe fouling on air preheaters (APHs) can even reduce a unit’s power output.

-

O&M

Ten Years of Experience with FAC in HRSGs

We first reported on combined-cycle plant reliability concerns due to erosive wear and flow accelerated corrosion (FAC) in heat-recovery steam generator (HRSG) pressure parts at the 1999 EPRI Maintenance Conference. More than 10 years later, these damage mechanisms remain significant contributors to forced outages, pressure part repairs, and major component replacement.

-

Water

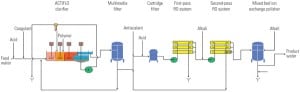

Mine Drainage: An Alternative Source of Water

Although mining practices often vary greatly according to the material produced and the value of the deposit, one common denominator is that mining of materials containing sulfide minerals creates acid mine drainage (AMD). AMD is one of the mining industry’s major environmental challenges.

-

Coal

Breathing Added Life into Failing Heat Exchangers

When heat exchanger tubes—sometimes numbering a thousand or more per unit—begin to crack or wear, the effects can lead to a cascade of subsequent failures in adjacent tubes. If too many tubes are plugged, heat exchanger effectiveness is compromised, and power generation may be curtailed. If conventional mechanical plugs are used, they can break loose, leak, and fail. At that point, the replacement of a very costly heat exchanger is imminent.