Focus on O&M

-

O&M

Optical Gas Imaging Camera Offers Hydrogen Leak Detection Solution

The operation of an electric power generator produces large amounts of heat that must be removed to maintain efficiency. Depending on the rated capacity of the generator, it might be air-cooled

-

O&M

Innovative Wind Turbine Blade Inspection and Maintenance Tools

The life of a wind turbine can be pretty precarious. The blades—made of laminated materials, such as composites, balsa wood, carbon fiber, and fiberglass—can reach speeds up to 180 miles per hour at the tip, which means even small particles in the air can cause damage to the surfaces. It’s probably no surprise that lightning […]

-

O&M

Innovative Pipe Conveyors: Effective, Efficient, and Environmentally Friendly

Transporting household and industrial waste as well as sewage sludge from a treatment plant to a power station can be a messy business. The utility company Linz AG found that a pipe conveyor system offered an optimal solution. The conveyor is not only highly energy efficient, but due to its closed design, it also allows […]

-

O&M

Advanced Bearing Technology Eliminates Subsynchronous Steam Turbine Vibrations

A facility’s steam turbine ranks at, or at least near, the top of the list of vital power plant equipment. Without it, the thermal energy in pressurized steam can not be converted to rotary motion, which is

Tagged in: -

O&M

Robotic Inspections of Nuclear Power Plant Storage Tanks

Nuclear power station water storage tanks, located above ground or underground, are constructed of aluminum, stainless steel, or carbon steel. All have naturally occurring electro-chemical processes that can eventually deteriorate the metal, resulting in leaks. Defects that develop on the underside of tank floors are particularly difficult to detect and measure. The Nuclear Energy Institute […]

-

O&M

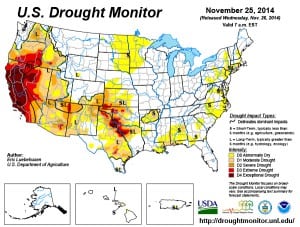

Global Water Outlook for Power Generation

Water and energy are intimately linked. Water is necessary for the production, distribution, and use of energy. Energy is needed for the withdrawal and delivery of water. The two are inseparable. Several

-

O&M

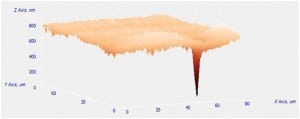

Inspecting Aberrant P91 Components for Integrity

Many utilities around the world have been discovering abnormal or aberrant P91 base and weld metal microstructures in their plants, leading to, or with a potential to lead to, early cracking and failure in

Tagged in: -

O&M

Portable Oil Analysis Tools Reduce Routine Maintenance Costs

What do a power plant, a hospital, a police station, and a remote mine have in common? They all have essential assets requiring uninterruptible power, commonly powered by an engine generator as primary or backup power. Engine generators, often termed “gensets,” combine an electrical generator and an engine. They supply electrical power where normal utility […]

Tagged in: -

Nuclear

Improved Resin Material Boosts Capture of Cobalt at Nuclear Plants

The Electric Power Research Institute (EPRI) has teamed with Purolite Corp. to begin the commercial manufacture of a new resin for removing radioactive elements from the internal water streams of nuclear power plants. The resin, called CoSeq, increases the amount and efficiency of cobalt (Co) removal compared to conventional resins. In-plant demonstrations have shown that […]

-

O&M

Proper Lubrication Practices Improve Plant Operations

Although industrial lubricants typically account for only 1% of plant operational costs (Figure 1), the lack of proper lubrication products, techniques, or applications can have a much more severe effect on

Tagged in: