David Brown, ENERCON Birmingham Office Engineering Manager

David Brown, ENERCON Birmingham Office Engineering ManagerBS ChE, Purdue University

Disaster Recovery Experience—A Fire and A Flood

Two fires rendered an entire power plant inoperable—Flooded power plant with design documents gone, brought back on-line in eight months with record production levels.

By David Brown

Multiple Fires Render Puerto Rico Plant Inoperable

PREPA’s (Puerto Rico Electric Power Authority) Palo Seco Generation Station experienced multiple fires that severely damaged the 600 MW plant rendering it completely inoperable. The fires destroyed the central control room, Unit 3 & 4 switchgear room and Unit 1 turbine generator, ISO-Phase bus and main step-up transformers. The distributed control systems wiring and raceway for the boiler control, burner management systems, turbine controls, switchgear and MCC controls were redesigned and replaced. For Unit 3 & 4 all power feeders, motor feeders and raceway were replaced. Virtually all control systems, wiring and raceway for the boiler controls, burner management system, turbine controls, switchgear and MCC controls had to be redesigned and replaced for Units 1, 2, 3 & 4.

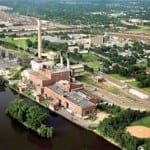

Flood Remediation Project at Coal Fired Power Plant

In the summer of 2008 Central Iowa received unprecedented rainfall resulting in devastating floods in Cedar Rapids and the surrounding area. Alliant Energy had two power stations affected by the flood including the station at Prairie Creek. The water level rose very quickly, flooding the basement and eventually reaching a level of four feet above the turbine room floor. The rapid rise of water did not allow sufficient time for an orderly shutdown of the five units on site. Consequently, three units shut down ‘hot.’

The control room, battery room, and the majority of electrical equipment and mechanical auxiliary equipment were located on the ground floor or in the basement. Each of the four coal fired boilers, one natural gas fired boiler, and three turbine generators sustained serious damage. Virtually all electrical power distribution equipment and many mechanical systems were damaged by the floodwater, requiring total replacement.

The initial phase of the project was to assess the mechanical and electrical damage and develop cost estimates and schedules to enable Alliant to make business decisions for returning the power station back to service. Approximately 1,400 items were assessed for a condition and remediation strategy. Within six weeks, the program switched from an assessment mode to a time critical remediation project.

Significant detail engineering was required because existing drawings that accurately defined the systems were either destroyed by the flood or were non-existent. A new Emerson Ovation DCS was installed, and the soot blower and turbine controls were moved to the new DCS. Also, many plant upgrades, building modifications, and plant betterment projects were implemented as a part of the overall project. Betterment projects included a new export steam piping system, replacement of boiler oil igniters with natural gas igniters, new SO3 injection system, new grate drives, new coal feeders, ball mill refurbishment, FD fan rebuild, and new coal distribution to burners including duct burners. The efforts included inquiry packages and purchase requisitions for all electrical, I&C, and mechanical equipment. Over 1,200 purchase requisitions were generated to support the flood remediation and betterment projects.

The first two units were operational eight months after the flood with all units operating at record performance within sixteen months.