Whether a power plant burns coal, gas or biomass – when process equipment has been in operation for many years, the question of modernisation inevitably arises sooner or later. By retrofitting intelligent electric actuators, existing plants can make the leap into the digital future.

There are plenty of reasons to modernise or replace process equipment such as actuators. Is a new control system to be introduced? Have the requirements for process accuracy increased? Perhaps there’s a drive to increase the level of automation across the plant, or to use digital tools to monitor the condition of equipment items to reduce unplanned shutdowns. Replacement with modern devices can also be worthwhile when equipment reaches the end of its service life and is failing more frequently, or when spares are no longer available.

Recent examples show that installing high-performance modern actuators can significantly increase the efficiency, process safety and availability of power plants, while also reducing operating costs. AUMA offers a wide range of state-of-the-art, high-performance electric actuators designed to meet all the requirements of modern power plant automation. In addition, experienced AUMA experts are available around the globe to manage all the challenges of a typical modernisation project.

Accommodating a new distributed control system

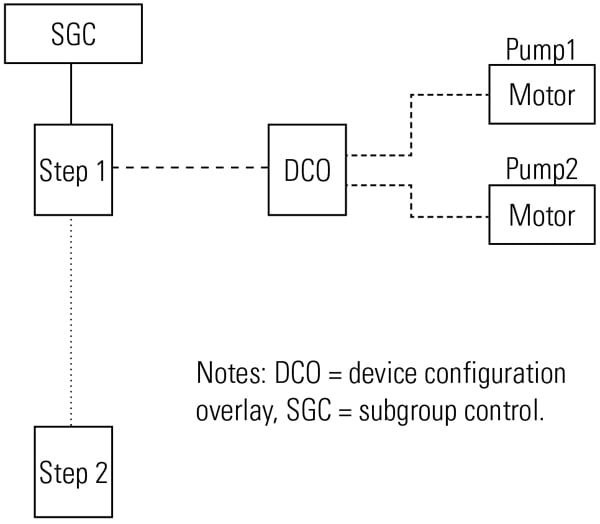

When a new distributed control system (DCS) is to be introduced, the communication standard used for field-level communication often changes as well. However, this does not always mean that entire actuators need to be replaced. For modular actuators such as the SA multi-turn and SQ part-turn actuators from AUMA, it may be sufficient to retrofit actuator controls with the appropriate interface, if the actuator itself is still in good condition. This saves investment costs and resources by extending the service life of existing assets. The actuators can be easily and seamlessly integrated into any modern DCS thanks to a choice of interfaces for all common communication systems, from classic fieldbus, like Profibus DP and Modbus RTU, to Industrial Ethernet such as Profinet, Modbus TCP and EtherNet/IP.

Unlocking digitalisation potentials

When the monitoring of field devices in a plant needs to be expanded, or when new diagnostic requirements arise that existing actuators can no longer meet, investing in modern, intelligent actuators often pays off. With integrated sensors and extensive operational data collection, AUMA actuators create the foundation for successful digitalisation. They automatically log a wealth of meaningful operational and device data, such as number of starts, motor runtime and temperatures, in a time-stamped event log. Thanks to automated analysis and diagnostic functions, in combination with CORALINK, the AUMA digital ecosystem, plant operators can obtain information about the current condition of their actuators at any time. For each actuator, the analysis recommends actions that should be carried out to ensure availability and avoid costly failures. Remote diagnostics via the control system is also possible.

Automating manually operated valves

Valves that rarely need to be operated may still rely on handwheels. With fewer staff available, however, and higher costs for their time, plant operators may now find it profitable to automate these valves by adding electric actuators.

Single-source project management

Experienced retrofit experts within the AUMA service organisation typically work together with the plant operator or planner to develop a customised modernisation plan for actuators across the plant. The first step is to analyse the conditions and specific requirements of the project, with the goal of always offering the most sensible and resource-efficient solution. The retrofit experts then take care of all phases of the project execution, from detailed on-site recording of dimensions and operating parameters for all valves, through the selection and design of suitable actuators from AUMA’s extensive portfolio, to smooth and timely installation and commissioning by qualified AUMA service technicians.

Case study 1: AUMA Profinet actuators increase plant sustainability

Retrofitting state-of-the-art, high-performance valve actuation technology can ensure efficient and sustainable plant operation. This is illustrated by the 241 AUMA electric actuators that have been installed at Stockholm’s largest combined heat and power plant, Kraftvärmeverk 1. The actuators are used to control all the processes in the combined heat and power plant: from the fuel supply, feed water and steam systems to flue gas cleaning and the connection to the district heating network. Using AUMA actuators with integral Profinet communications brought major advantages: high reliability thanks to integrated redundancy, easy and flexible integration, and advanced diagnostic options. Overall, the AUMA actuators help to improve the efficiency, reliability and safety of the CHP plant, and have reduced the operating costs.

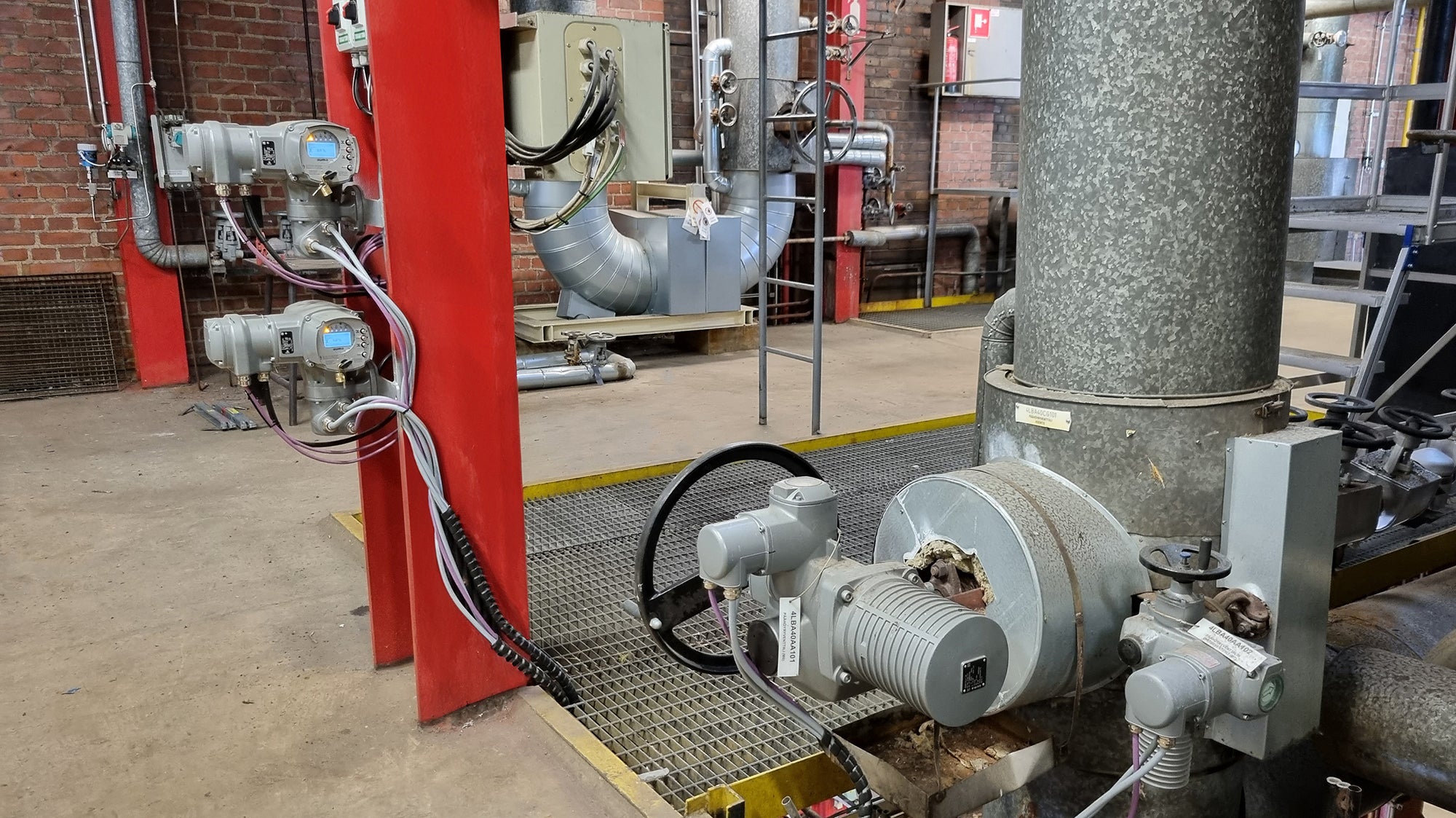

Case study 2: Enhanced process efficiency thanks to automation of manually operated valves

By retrofitting AUMA actuators, the Nokianvirran Energia biomass power plant in Nokia, Finland, significantly increased its degree of automation and thus maximised process efficiency. The AUMA actuators now automate valves that previously were manually operated, reducing the time to start up the boiler from zero to full power from 30 minutes to just six minutes. Thanks to Profibus interfaces in the actuator controls, the actuators are remotely controlled from the central control room via Profibus DP. In areas subject to heavy vibration or high process temperatures, the modular product design allows the actuator controls to be mounted on wall brackets at a distance from the actuators, so as to protect the electronics.