Latest

-

It’s all about power

—Dr. Robert Peltier, PE Editor-in-Chief The Lieberman-Warner Climate Security Act (L-W) that proposes to cut carbon emissions by two-thirds by 2050 was delivered stillborn on the Senate floor in early June, as expected. Faced with public outcry over record-high gasoline prices, no senator was able to breathe life back into a bill that is estimated […]

-

Commentary

Kilowatt-hour tax is fairest approach

By Jim Rogers, Duke Energy Corp. The climate change debate has been dramatized in movies, on Hollywood’s red carpets, and in documentaries featuring melting ice caps. The collective effect is extraordinary, and positive. America now stands ready to address one of its toughest challenges since the industrial revolution—decarbonizing our energy supply and economy. Now the […]

-

Coal

Global Monitor (July 2008)

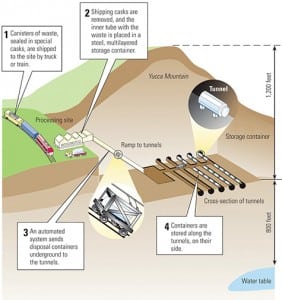

Yucca Mountain plan sent to NRC/ CPV cells get cooling chips from IBM/ StatoilHydro to pilot test first offshore floating wind turbine/ U.S. rivers next massive power source?/ Siemens delivers 500-MW gasifiers/ Algae: A green solution/ POWER digest

-

O&M

Focus on O&M (July 2008)

Protection against arc flash more important than ever; Laramie River Station uses new coating technology; Protecting power plant pipes: Basics you must know

-

Legal & Regulatory

Climate change: Policy via litigation?

By Steven F. Greenwald and Jeffrey P. Gray David Crane, the CEO of NRG Energy, was recently quoted in a widely disseminated publication as saying: “It is a moral imperative that we take steps to reduce CO2 concentration in the earth’s atmosphere.” One might expect those reacting to Crane’s comments (made in a February 2007 […]

-

Business

Generation next: Strategies for recruiting younger workers

In our April 2008 issue, the article “The aging workforce: Panic is not a strategy” focused on how to reconfigure human resource practices in order to find enough well-trained new personnel to replace the large number of baby boomers who will be retiring in the next few years. This month we profile several utilities that are using innovative approaches to recruit younger technical staff and skilled craft labor to fill positions being vacated in growing numbers by retiring employees.

-

Coal

Luminant’s Big Brown Plant wins for continuous improvement and safety programs

Staff from Luminant’s Big Brown Plant accepted the PRB Coal Users’ Group’s top honor for innovative improvements to coal-handling systems and a sterling safety record. The numbers reveal their accomplishments: an average EFOR less than 4%, an availability factor averaging 90% for a plant that burns a lignite/PRB mix, and staff who worked more than 2.6 million man-hours since March 2000 without a lost-time injury.

-

Coal

Options for reducing a coal-fired plant’s carbon footprint, Part II

A conventional coal plant’s CO2 emissions can be reduced either after combustion (see Part I of this article in POWER, June 2008) or before. In the latter case, typified by integrated gasification combined-cycle (IGCC) plants, the fuel used is synthesis gas (syngas), which contains mostly hydrogen (H2) and CO. A water-shift reactor converts the CO […]

-

Coal

Woods and power company CEOs agree: “The state of the industry is cautious”

It is rare indeed to witness, at an otherwise staid industry forum, the public rebuke of the country’s most prominent supplier to the electric power industry. But at the Keynote session and Power Industry CEO Roundtable of the 2008 ELECTRIC POWER Conference & Exhibition in Baltimore this May, Milton Lee, general manager and CEO of […]

-

Coal

Carbon Constraint Conference: Dealing with the climate change conundrum

“Once it’s enacted, the impact of climate change legislation on the electric power industry will be ten times bigger than that of the Clean Air Act,” said Dan Adamson, an attorney with the law firm of Davis Wright Tremaine and chair of the opening session at the 2nd Annual Carbon Constraint Conference (Figure 1). 1. […]