Latest

-

News

Rethink wind strategy, Carbon Trust tells UK government

The UK will build only a quarter of the 29 GW of offshore wind farms needed to reach its target to have 15% of energy from renewable sources by 2020 unless the government acts urgently to reduce costs and risks to developers, a government-funded but independent think tank said in a report launched last week. […]

-

News

Appellate court upholds Indiana commission’s approval of IGCC plant

The Indiana Court of Appeals on Thursday ruled against four environmental and consumer groups and upheld a decision by state regulators to allow Duke Energy to build a $2.35 billion integrated gasification combined cycle (IGCC) plant at its coal and oil–fired Edwardsport facility in Knox County, Ind. Duke and Southern Indiana Gas and Electric Company […]

-

News

PJM board announces $1.8 billion for transmission improvements

PJM Interconnection has approved $1.8 billion in electric transmission system additions and grid upgrades to enhance the reliability of its power supply system. The grid operator’s system serves parts of 13 states and the District of Columbia. On Friday, it said the upgrades and improvements authorized by its board comprised dozens of projects. Most new […]

-

News

GDF Suez threatens court action if Belgium imposes nuclear levy

Belgian utility Electrabel has threatened legal action if the country’s government enacts a bill that would force the its two nuclear operators to pay a € 250 million ($336 million) tax. The one-time levy would force Electrabel and SPE to contribute to the 2008 financial year. If they do not comply, a penalty of 2% […]

-

News

ISO New England releases 10-year plan for region’s power system

A regional system plan for 2008 released Friday by ISO New England Inc. forecasts that the region is likely to have sufficient capacity to meet electricity demand through 2014, but significant challenges—such as major transmission upgrades—remain for the region New England Inc. is the operator of the region’s bulk power system and wholesale electricity markets. […]

-

Coal

J.K. Spruce Power Plant, Unit 1, San Antonio, Texas

Top Plant: CPS Energy’s J.K. Spruce Power Plant, Unit 1 was recently recognized by the EUCG Fossil Productivity Committee as the best performer in the large coal plant category over the 2002-2006 evaluation period. The competition was tough, with more than 80 plants in the running, but Unit 1 emerged as the clear winner by earning top points for high plant reliability and very low nonfuel O&M costs.

-

News

Hand-arm vibration gauge

No U.S. federal standards exist to limit worker exposure to hand-arm vibration (HAV), but the National Institute for Occupational Safety and Health suggests that high HAV acceleration levels (5-36 m/s2) can cause physical effects—and even permanent injury—if left unchecked and untreated. A new series of triaxial accelerometers launched this August by PCB Piezotronics’ Larson Davis […]

-

Legal & Regulatory

Texas loses “food vs. fuel” biofuel feud

How often do you get a clash between two great Lone Star icons?

-

Coal

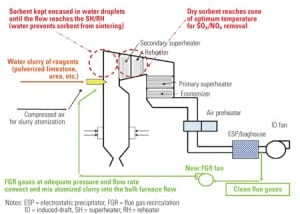

Bringing down the cost of SO2 and NOx removal

A twist on an old technique, flue gas recirculation, helps prevent slagging in the upper furnace and convective pass, according to pilot testing recently completed by APTECH CST and the Southern Research Institute. The technology—along with a companion technology for furnace sorbent and urea injection for SO2 and NOx control—could help owner/operators of smaller, older coal-fired plants meet emissions limits at a reasonable cost.

-

O&M

Managing software life-cycle issues

Software ranges from shrink-wrapped products available “off the shelf” to custom corporate implementations of enterprise systems that require sessions with shrinks to keep everyone sane. Regardless of its complexity, every piece of software a plant uses, or interfaces to, poses critical issues that require life-cycle management. Although functionality has always been the chief specification for software, plants must pay far more attention to long-term quality issues. These two concerns are often at odds with each other.