O&M

-

O&M

Benchmarking Nuclear Plant Operating Costs

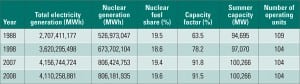

In an exclusive agreement with the EUCG Nuclear Committee, POWER was provided access to some key, high-level performance and operational data from the group’s nuclear industry benchmarking database. All U.S., and many international, nuclear power plants are members of the committee and have contributed to its database for many years. This month we introduce you to the EUCG Nuclear Committee and share sample nuclear operating costs. Look for future reports on other key performance benchmarking metrics during 2010.

-

O&M

Condenser Tube Life-Cycle Economics

The decision to retube a heat exchanger or condenser begins with understanding why tubes are failing. Only when the “why” is understood can the economic replacement tube material be selected. We explore the most common tube material failure mechanisms and then illustrate how to perform a proper life-cycle analysis for that new set of condenser tubes your plant so desperately needs. In sum, there are many reasons to consider getting the copper out of your condenser.

-

O&M

Texas Wind Boom Cutting into Fossil Generator Profits

Can wind turbines actually reduce the amount of fossil fuels consumed? A Wall Street Journal analysis concludes that ERCOT utilities will begin to feel the squeeze in their profits this year and to expect the amount of fossil fuels used to generate electricity to be reduced.

-

O&M

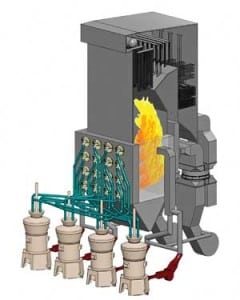

Zonal Combustion-Tuning Systems Improve Coal-Fired Boiler Performance

Coal-fired power plants that fire low-cost coals or that are equipped with combustion modifications for NOx controls are challenged with maintaining good combustion conditions while maximizing generation and minimizing emissions. In many cases, significant unit derates, availability losses, and an increase in unburned carbon levels can be attributed to poor combustion conditions that occur as a result of poorly controlled local air/fuel distribution within the boiler furnace. Fortunately, a new generation of combustion optimization technologies is available that uses burner air and fuel controls and spatially distributed combustion monitors to detect and correct local furnace air/fuel distribution imbalances.

-

O&M

Ensure Your Valve Replacement Parts Meet OEM Specs

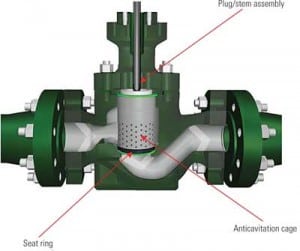

When high-temperature boiler feedwater passes through a control valve, the pressure drop can exceed several thousand pounds per square inch, placing extreme stress on the valve body and internal parts. If those parts are not engineered and manufactured to the highest industry standards, there is a very real possibility of the severe conditions damaging or destroying the valve.

-

O&M

Update: Benchmarking Boiler Tube Failures

Boiler tube failures continue to be the leading cause of downtime for steam power plants. Is your boiler tube failure reduction program showing improvement when compared to programs at peer plants? The EUCG’s recent update of its boiler tube failure study can help you answer that question. The full study is available only to members, but this POWER exclusive presents many of the key results, which could help you improve the operation of your plant.

-

O&M

Measuring Coal Pipe Flow

Once pulverized coal flows have been measured, they can be balanced and optimized. Until then, tuning is simply guesswork. The right way to balance furnace fuel flows is to establish solid baseline performance by proper measurement of fuel flow, fineness, and velocity. Only then can all the coal pipes be accurately balanced and followed by a tune-up of the boiler controls.

-

O&M

Proper Valve Selection Reduces Downtime, Increases Process Efficiency

Many customer quotation requests provide only the line size, pressure class rating, and valve type. A typical request might read: size 4, Class 900 globe valve. Though this may be enough information to produce a valve quote, it rarely is enough information to size the best valve from both a performance and cost perspective.

-

O&M

Avoid These 10 Mistakes When Selecting Your New Water Treatment System

There are a number of reasons why your plant might be looking at new water pretreatment equipment in the near future. One common reason is the addition of new generating capacity. Regardless of the type of new generation, you can be sure that it will require additional high-purity water for processes ranging from direct steam generation to power augmentation, NOx control, and washing the blades of the combustion turbines.

-

O&M

Top Plants: Portlands Energy Centre, Ontario, Canada

Construction of the Portlands Energy Centre was a logistical dream: A mothballed power plant next door had an active switchyard, natural gas pipeline, and cooling water structure. The new facility put peak power into the Ontario Power Authority’s grid from its two combustion turbines only two years after collecting the necessary permits. The entire plant entered commercial service on April 23, 2009 — six weeks early.