O&M

-

O&M

Predictive Maintenance That Works

This installment of the series continues our review of different conditioning-monitoring techniques commonly in use at power plants using any generation technology. In the May issue we began exploring specific PdM techniques with an examination of electrical surge comparison and motor-current signature analysis.

-

O&M

Defeating Concrete Reinforcing Steel Corrosion

Four concrete cooling towers at a coal-fired electrical generation plant exhibited reinforcing steel corrosion that was causing concrete deterioration. This case study follows the repairs to those towers—how the corrosion control solution was selected, how repairs were made, and how follow-up tests found the repairs to be effective three years later.

-

O&M

Titanium Tubing Still Going Strong After 40 Years

Since 1972, titanium-tubed power plant surface condensers have been providing corrosion-free service. Recent process advances are making the material suitable for even more applications.

-

O&M

Solid Fuels: Moving Material and Managing Emissions

In today’s solid-fueled power plant, managing emissions and moving materials more defines the task than the traditional work of making megawatts. That’s the message that emerged from the coal and solid fuels track at this year’s ELECTRIC POWER.

-

O&M

Artificial Intelligence Boosts Plant IQ

Neural networks have already found practical application in many plants, and recent advancements in artificial intelligence promise to shape the design of the next generation of power plant supervisory controls. Will future plant operators be fashioned from silicon?

-

O&M

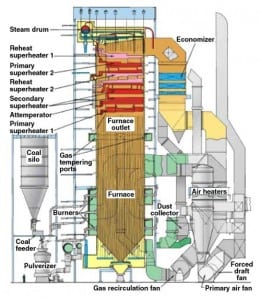

Applying CFD to Optimize Furnaces Cofiring Biomass, and the Impact of Cofiring on SCR

The international policy framework regulating the emissions of greenhouse gases from industrial and utility boilers is in flux. Meanwhile, most boiler owners are evaluating potential strategies for when, not if, more stringent emissions reduction regulations are put in place. One of the most attractive compliance options is the cofiring of biomass in existing coal-fired boilers.

-

O&M

Air Preheater Uses New Adaptive Brush-Sealing Design

Radial, axial, and circumferential metallic seals installed on rotary, regenerative air preheaters have evolved little from the original metal strip designs that date back to the original Ljungström preheaters developed nearly a century ago. Unfortunately, metallic strip seals degrade soon after installation, allowing excessive air-to-gas leakage, which translates into increased fuel consumption and fan power.

-

O&M

Preventing Copper Deposition in Steam Turbines

Many large utility-scale units with copper alloy condensers and feedwater heaters lose generating capacity when copper and copper oxide deposits develop on high-pressure (HP) steam turbine blading. It is not unusual for a 400-MW unit to lose 10% of its generating capacity over a six-month period when water treatment processes aren’t properly tuned to prevent copper transport in the steam and condensate systems. In fact, one utility reported that it lost 20 MW of capacity in one month because of such deposits. The financial implications of such deposits, particularly in power markets where plants are pushed to their generating limits, are tremendous.

-

O&M

Predictive Maintenance That Works

This series of articles focuses on the nuts and bolts of predictive maintenance (PdM), also known as condition-based maintenance. A well-defined and well-executed PdM program saves time and money by reducing unneeded time-based maintenance tasks and by identifying and fixing problems before they cause equipment failure or plant shutdown. In this article, we begin introducing condition-monitoring techniques commonly in use at power plants.

-

O&M

Condenser Performance Improvement Through Innovative Cleaning and Leak Detection Technologies

One of the largest returns on investment a plant can achieve is the improved condenser performance that results from an effective condenser tube cleaning. Perhaps it is time to reevaluate your choice of cleaning technologies, establish an optimal cleaning schedule, and add routine air and water in-leakage surveys to your plant’s maintenance schedule.