O&M

-

O&M

The End of the Line for Pipe Cleaning with Natural Gas?

Piping at gas-fired plants has long been cleaned using compressed natural gas because of its easy availability. The big problem? It’s also explosive. The fatal 2010 blast at the Kleen Energy plant in Connecticut began a shift toward safer alternatives such as nitrogen and compressed air that is gathering increasing momentum.

-

O&M

Virtual Co-Driver to Improve Truck Safety

POWER recently talked with Erika Jakobsson, a project manager at Volvo Technology in Gothenburg, Sweden, who is responsible for developing intelligent trucks in response to European Union (EU) directives.

-

O&M

Condenser Backpressure High? Check Vacuum System Sizing

In a power plant, the primary use of vacuum systems is to remove air and other noncondensable gases from the shell side of the condenser in order to maintain design heat transfer and thus design vacuum. If holding condenser vacuum is a persistent problem, one often-overlooked cause is an inadequately sized vacuum system.

-

O&M

Avoiding Flow-Induced Sympathetic Vibration in Control Valves

Compressible fluid flow through control valves will inevitably cause some form of flow-induced vibration in the fluid system. Identifying the type and cause of the vibration requires detective work. Determining the design changes required in the valve and fluid system to prevent the vibration from occurring requires advanced analytical techniques.

-

O&M

Audit Your Coal Dust Prevention Program

The hazards of coal dust accumulation in power plants are familiar to coal-fired plant operators. Operators of plants that burn Powder River Basin coal are particularly aware of necessary housekeeping and fuel-handling practices, but any plant that allows excessive amounts of coal dust to accumulate is playing Russian Roulette with its staff and equipment.

-

O&M

Constructing and Managing Coal Ash Landfills

Creating a landfill to hold dry boiler ash is a challenging proposition these days. There’s more to the project than you might imagine, as you’ll learn from this article about the development of a typical new ash landfill.

-

O&M

Collecting Dust

Rules requiring removal of combustible dust from the workplace will undoubtedly improve worker safety and health. A survey of equipment suppliers finds a variety of dust collection systems are available to meet just about every dust collection need in the power house.

-

O&M

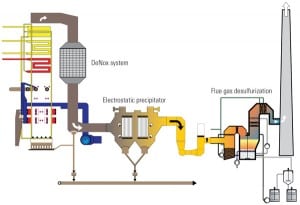

Level Switches Keep Electrostatic Precipitators Online

Measuring the level of dust and fly ash collected in electrostatic precipitators (ESPs) is a very difficult technical problem. At one utility, level switches were so unreliable that operators could not trust their readings because failures were so frequent. When a switch did fail, the precipitator would often clog up, costing the utility up to $100,000 in downtime and repair costs.

-

O&M

Marmaduke Award Trophy Presented

The 2011 Marmaduke Award winner was CTG Universidad, a two-unit combustion turbine plant built in the early 1970s in Monterrey, Mexico. The award was made to the plant in recognition of its upgrade of one 14-MW unit to operate as a synchronous condenser, thus relaxing power restrictions caused by a lack of sufficient reactive power production in the north of the city. More reactive power production by this urban plant also allows delivery of more power produced by efficient combined cycle plants located outside the city, because it reduces the amount of reactive power that must be moved over transmission lines.

-

O&M

EPRI Bridges Industry R&D Gaps

The technologies used to generate and distribute electricity will be radically transformed during the coming decade. Amid that change, the power industry must continue to meet customer reliability, safety, and cost-of-service expectations. Achieving the right balance among these often-conflicting goals is the primary focus of every utility. The Electric Power Research Institute is helping utilities achieve that balance with R&D programs for many new and emerging technologies.