O&M

-

Legal & Regulatory

Is an Automated Compliance Tracking Solution Right for You?

Like so many other power plant functions these days, regulatory and standards compliance can be automated. Know what you want an automated system to do before you make a vendor decision. As North American Electric Reliability Corp. (NERC) Critical Infrastructure Protection (CIP) enforcement deadlines and audit dates loom—notably, CIP-003-6 in April 2017, which addresses the […]

Tagged in: -

O&M

High-Speed Turbine Rotor Balancing Lowers Costs and Improves Operation

High-speed turbine rotor balancing was once rare because of the costs and logistical challenges involved in doing it during an outage. That’s begun to change as economic options emerge, and experience is showing that high-speed balancing can pay big dividends in reliability and maintenance costs. To a maintenance engineer or fleet manager, unwanted vibration in […]

Tagged in: -

O&M

A Primer on Gas Turbine Failure Modes

When a gas turbine goes down, recovery can be an expensive, time-consuming process. Knowing what can go wrong and how to anticipate turbine failures can help you avoid a difficult unplanned outage. Gas-fired power is hot and getting hotter. The Energy Information Administration estimates that 2016 will be the first year ever that the U.S. […]

-

O&M

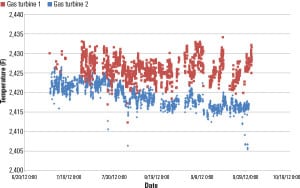

Efficient Use of Power Plant Process Data Improves Asset Management

Asset data is crucial in the power generation industry. Without it, utilities are forced to speculate about how long their assets will last, when they will need repair, and which strategies will maximize plant efficiency. With it, plant owners have the tools to drive down operational and maintenance costs while ensuring highly reliable power delivery. […]

Tagged in: -

O&M

HRSG Condition Assessments Identify CAPEX, Maintenance Priorities

As combined cycle gas turbine plants are called upon to play a larger and more flexible role in the generation mix, it’s important to schedule a comprehensive assessment of major components at key intervals to ensure reliable operation. Just like humans, power plants can benefit from regularly scheduled condition assessments, which are sometimes called “health […]

Tagged in: -

Partner Content

Sulzer expands facility capability with new lathe

Industrial gas turbines are increasing in size. As a result of this, repair facilities that overhaul and repair these machines must keep pace. One of the key tools is a large lathe. As one of the leading industrial gas turbine and rotor repair providers in the world, Sulzer has recently upgraded its service center in

-

O&M

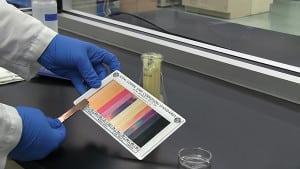

All About Lubricant Additives

Lubricant additive technology is a complicated business because it involves several different chemistries. Often, one additive can adversely interact with another additive as they both compete for the same area on substrate surfaces. This kind of interaction can lead to the canceling of the additives’ desired properties. Conversely, the use of different additive chemistries can, […]

Tagged in: -

Partner Content

Sulzer Service Solutions

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of large rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of technically advanced remanufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace-of-mind to focus

-

Partner Content

Red and green to grey — Why switch my HMI?

Many operators are perfectly happy with their trusty red and green HMIs and can’t imagine why they should give them up for a dull greyscale display. When they take a closer look, they usually find out that grey is beautiful.

-

O&M

Boiler Tube Failure Thermohydraulic Analysis

Eskom operates 23 power stations in South Africa with a total capacity of more than 42 GW. It supplies about 95% of all the electricity used in the country. One of its coal-fired power stations was experiencing frequent boiler tube fatigue failures in the hopper section—the bottom part of the boiler—of all six units. The […]

Tagged in: