Instrumentation & Controls

-

O&M

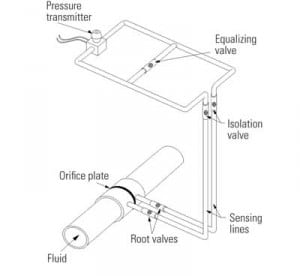

Pressure-Sensing Line Problems and Solutions

Improper pressure-sensing line design or installation is often found to be the cause of poor sensing system accuracy and response time. Here’s how to identify and solve those pesky pressure sensor problems in short order.

-

Instrumentation & Controls

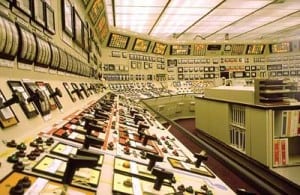

Digital Networks Prove Reliable, Reduce Costs

The debate over the benefits of using digital bus networks as the communications backbone of new power plants is all but settled. The technology is maturing, and the reliability of digital hardware is superior to that of hardwired systems. Newmont Gold Mining’s 200-MW TS Power Plant is perhaps the power industry’s best example of how a plantwide digital controls architecture can provide exceptional reliability and be significantly less costly to install.

-

O&M

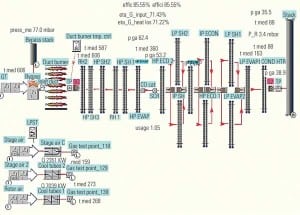

Computer Simulation of HRSGs Can Improve O&M

Obtaining accurate data about the performance of a plant’s heat-recovery steam generator is crucial to ensuring the smooth operation and maintenance of the equipment. Software designed to model and simulate HRSG operations can provide valuable information about corrosion and other operational problems.

-

O&M

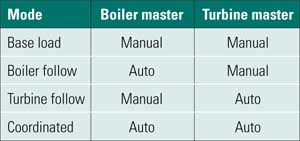

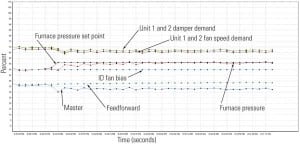

Boiler-Tuning Basics, Part II

Boilers have enormous thermal mass and are relatively slow to react. Turbines are nimble and quickly answer an operator’s command. Coordinating an entire plant requires an intimate knowledge of both systems and selecting the right logic tools to bring them together.

-

O&M

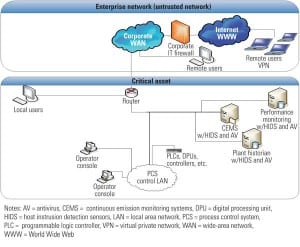

Helping Power Plant Control Systems Achieve NERC CIP Compliance

This guide offers suggestions from a control system engineering perspective for protecting power-generating units that are determined to be critical cyber assets

-

O&M

Reduce Costs with Wireless Instrumentation

New wireless technologies for power plant instrumentation offer significant cost savings when compared to traditional wired networks. The value of this cost savings is especially relevant in the highly competitive power industry, where aging facilities are common and upgrades are an expensive necessity. Modern wireless networks offer a reliable upgrade path that even provides some unexpected benefits when compared to traditional copper networks.

-

O&M

Boiler-Tuning Basics, Part I

Tuning power plant controls takes nerves of steel and an intimate knowledge of plant systems gained only by experience. Tuning controls also requires equal parts art and science, which probably is why there are so few tuning experts in the power industry. In Part I of a two-part series, we explore a mix of the theoretical and practical aspects of tuning boiler controls.

-

Instrumentation & Controls

ISA POWID: Where Power Computing Professionals Meet

Which new and emerging technologies will be essential to your power plant’s success? Our special cover story series gives you a glimpse into the future of advanced distributed controls, wireless applications, and automation technologies.

-

Instrumentation & Controls

Distributed Control Technology: From Progress to Possibilities

The past decade has seen an explosion of technology that has significantly altered the process control industry. The adoption of commercially available technology driven by desktop computing has allowed suppliers to focus on applications to enhance the process and deliver ever-greater value to the user.

-

Instrumentation & Controls

Optimize Your Plant Using the Latest Distributed Control System Technology

Distributed control systems are powerful assets for new and modernized power plants. Thanks to three product generations of technology innovations, these systems now provide new benefits — including improved O&M efficiency, greater plant design flexibility, and improved process control and asset reliability — that help competitive plants advance in the game.