Instrumentation & Controls

-

O&M

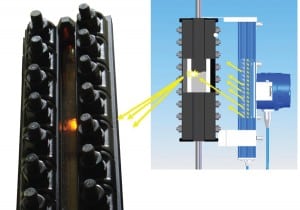

Point Level Capacitance Switch for Fly Ash Hopper Measurement

If you’re the person tasked with controlling the level of fly ash in collection hoppers, you know how difficult the application can be. What at first looks like a simple measurement quickly proves to be much more demanding in actual execution. The first problem is the environment inside the collection hoppers, which is extremely challenging […]

-

O&M

Gaining Control with Electraulic Actuators

Plant engineers at Eskom’s Majuba Power Station in South Africa have been continuously looking for ways to improve efficiency and reliability. The six-unit, 4,000-MW, supercritical coal-fired plant was experiencing an efficiency decrease of 5% to 7%, which plant engineers determined was caused by poor performance of the actuators on their condensate level control valves (CLCVs). […]

-

Instrumentation & Controls

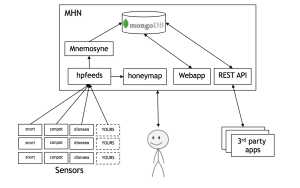

How to Use “Honeypots” to Overcome Cybersecurity Shortcomings

Cybersecurity threats facing the power industry have escalated dramatically in the past few years, as state-sponsored, organized crime, and hacktivist groups all seek to infiltrate U.S. energy infrastructure for cyber-espionage and sabotage purposes. A recent example of the severity of this threat can be seen in operation “Energetic Bear”—a Russian campaign to infect U.S. and […]

-

Renewables

Net Metering Not Necessarily a Burden on Those Without Solar

Nevada utility NV Energy’s net metering program does not significantly impact homeowners without rooftop solar, according to a study prepared for the Nevada Public Utilities Commission (NPUC) this month. The study was conducted by San Francisco–based Energy and Environmental Economics (E3) at the request of the NPUC after the passage of a Nevada law last […]

-

O&M

New Enclosure Solution Enables Remote Monitoring of Battery Backup Systems

With 4.4 million customers and nearly 46 GW of generating capacity, Atlanta-based Southern Co. has doubled the size of its supervisory control and data acquisition (SCADA) system in the past three years and

-

Nuclear

EPRI and Luminant Collaborate to Create Common Understanding of Cybersecurity Requirements

Nuclear utilities are facing stringent cybersecurity requirements for plant digital assets that fulfill safety-related, important-to-safety, security, and emergency preparedness functions or that are

-

Instrumentation & Controls

What You Need to Know Before Replacing Your Control System

Power plants were among the leaders in implementing distributed control systems (DCSs), starting in the 1980s with systems based on mini-computers and continuing through the turn of the century. Although many

-

Coal

Drones Promise Faster, Easier Inspection of Boilers, Stacks, Towers, and More

Mention the word “drone,” and most people will have a mental picture of what a drone is and does. They likely will think first of military drones carrying missiles and other weapons that could malfunction

-

Legal & Regulatory

GE Executive Markhoff Talks About the Water/Energy Nexus

Source: POWER During IHS CERAWeek in Houston in early March, POWER Editor Gail Reitenbach sat down with Heiner Markhoff, president and CEO of GE Power & Water’s Water & Process Technologies, to ask him about several issues of concern to power plants. Though the “water/energy nexus” theme has gained prominence recently, Heiner Markhoff’s comments underscored […]

-

O&M

Upgraded Control Room Consoles Improve Ergonomics

Great River Energy (GRE) is a not-for-profit electric cooperative that generates and transmits power for 28 member cooperatives throughout southern, central, and northern Minnesota and northwestern Wisconsin

-

Coal

Establishing Proper Pressure Drop for Feedwater Flow Control Valves

In power plants with drum-type boilers and constant-speed main boiler feed pumps, the feedwater control valve (also referred to as the drum level control valve) provides the means for controlling flow to the

-

Instrumentation & Controls

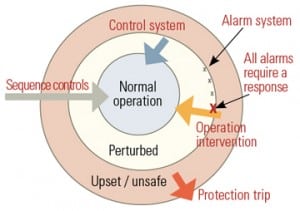

Generation Cybersecurity: What You Should Know, and Be Doing About It

Cybersecurity has become a topic of interest over the past year in generation, owing to new developments in North American Electric Reliability Corp. Critical Infrastructure Protection (NERC CIP) regulations

-

Coal

Remote Monitoring and Diagnostics Within a Smart Integrated Infrastructure

It seems as if each week brings further bad news for coal power plants. Recently, Consumer’s Energy sought relief to close three power plants, South Carolina Electric & Gas announced it would cease

-

Coal

The Power Plant Controls Market in China

In an email interview with POWER, Xue Wei, manager for Emerson Process Management Power & Water Solutions, China Business Development, provided some insight into the current state of control systems for Chinese power plants. His responses, edited for style, follow. POWER: How widespread are “state-of-the-art” control systems (yours and others) in new generating plants in […]

-

Instrumentation & Controls

Power Plant Training Simulators Explained

Training simulators are worth their weight in gold to the power industry, as well as to most process industries in general. People tend to learn the fastest and the most thoroughly when hands-on trial and

-

O&M

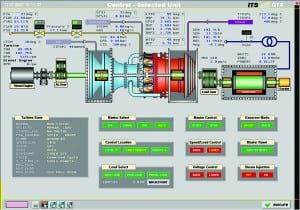

Considerations When Upgrading Gas Turbine HMIs

Aging human machine interface (HMI) hardware will eventually become a burden on plant operation. Obsolete HMIs can cause problems with connectivity, historical data loss, and hardware failure. As the hardware

-

Instrumentation & Controls

Quantum Cryptography Promises Un-Hackable Industrial Communications

Cybersecurity awareness and best practices are increasingly central to the power generation, transmission, and distribution industry. Industrial cybersecurity concerns, recently heightened by awareness of how

-

Instrumentation & Controls

What You Need to Know (and Don’t) About the AURORA Vulnerability

Perhaps because the public has been more obsessed in recent years by cybersecurity breaches involving everything from social media accounts to classified military secrets, the amount of attention given to the

-

Instrumentation & Controls

New ISA Cybersecurity Standard Published for Industrial Control Systems

A recently published standard has been adopted globally to address risks arising from the use of business information technology (IT) cybersecurity solutions to address industrial automation and control systems (IACS) cybersecurity in complex and dangerous manufacturing and processing applications. The ISA-62443 series of standards, being developed by the ISA99 committee of the International Society of […]

-

O&M

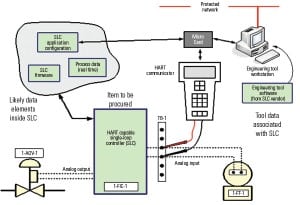

Industrial Wireless Sensors: A User’s Perspective

There are many reasons to anticipate that the use of wireless instrumentation in industrial settings will increase dramatically in the next few years.

-

Instrumentation & Controls

Quantum Cryptography Promises Un-Hackable Industrial Communications

What if you could send a control message between two points on the electricity grid—say between a control room operator and a turbine or between a system operator and a generating plant—and know that there’s no way that message can be intercepted, altered, or spoofed to effect malicious ends? That possibility may be only a couple of years away.

-

Instrumentation & Controls

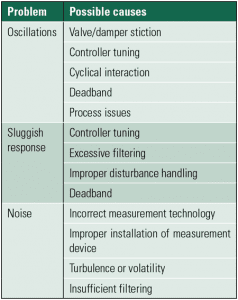

Troubleshooting and Solving Poor Control Loop Performance

Only through proper troubleshooting and then solving the underlying problems can control loop performance be improved. Process design certainly plays a role in control loop performance, but experience has shown that the majority of control loops can perform better—provided that the root cause of the poor performance is found and corrected.

-

Instrumentation & Controls

House Holds Cyber Threat Hearing as NIST Begins Preliminary Work on Cybersecurity Framework

Panelists at a House hearing on Tuesday held to examine steps the federal government and private sector are taking to bolster the nation’s critical infrastructure security shed light on the extent and variety of possible cyberattacks and called for flexible solutions. The hearing was held days after the National Institute of Standards and Technology (NIST) released its initial analysis of hundreds of comments submitted in response to President Obama’s February 2013 cybersecurity executive order.

-

Instrumentation & Controls

Newly Developed Software Isolates Cyber Attacks on Networked Control Systems

A software algorithm developed by researchers from North Carolina State University promises to detect and isolate cyber attacks on networked control systems.

-

Nuclear

Mexico Uses Nuclear Plant Simulator for Safe Training

Mexico’s Federal Electrical Commission needed a safe way to train new operators at its Laguna Verde Nuclear Power Plant in Veracruz, so it developed a stand-alone process simulator that allows trainees to practice a wide variety of plant operations and responses to incidents without putting the plant itself at risk.

-

Coal

ARPA-E Plays Matchmaker for Innovative Energy Research Projects

The Advanced Research Projects Agency-Energy (ARPA-E) may be the most important federal agency many in the power industry have never heard of. Whatever generation technology you are associated with, ARPA-E’s work will affect its future.

-

Nuclear

THE BIG PICTURE: Nuclear I&C

Progress in electronics and information technology has created incentives to replace traditional analog instrumentation and control (I&C) systems in nuclear power plants with digital I&C systems, or systems based on computers and microprocessors. About 40% of the world’s operating reactors have been modernized to include at least some digital I&C systems, according to the International […]

-

Instrumentation & Controls

Drum Level Instrumentation Update

Accurate knowledge of the water level in any boiler drum application is an absolute necessity. While operating a boiler with low water level is one of the leading causes of boiler failure, operating with a high water level may produce less-than-optimal steam, as well as damage to the steam turbine by moisture carryover.

-

Instrumentation & Controls

Plant Automation Advancements: The Australian Experience

Many recent utility greenfield and rehabilitation power projects have incorporated plant automation, with the goal of reducing the number of operators needed. The essential design principle is to specify control systems and field devices that will achieve the desired operational regime. Here’s how it’s done “Down Under.”

-

Instrumentation & Controls

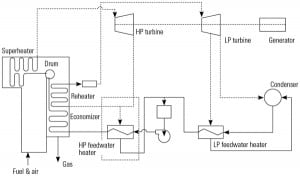

Coordinated Feedwater Heater Energy Control

The increased use of intermittent renewable energy sources and the shift to gas-fired combustion turbines places new burdens on the dispatch of many coal-fired units. Steam units must now operate at very low minimum load while maintaining the ability to ramp up and down quickly. High-pressure feedwater heater energy control can improve the system response of such coal-fired units.