Coal

-

Coal

Monticello Steam Electric Station, Mount Pleasant, Texas

Why does Monticello, a 30-year-old plant, deserve recognition as one of POWER’s Top Plants of 2006? Because TXU has been blending Powder River Basin (PRB) coal with local lignite at the plant for the past decade, and steady reductions in air-pollutant emission rates have been the result. That positive experience has made the company confident enough to propose building nearly 9,100 MW of new coal- or lignite-fired capacity in Texas by 2010 at a cost of $10 billion. Read on to share some of the lessons that TXU has learned about handling PRB coal safely.

-

Coal

Coal: The cornerstone of America’s energy future

In April 2005, U.S. Secretary of Energy Samuel W. Bodman asked the National Coal Council to develop a “report identifying the challenges and opportunities of more fully exploring our domestic coal resources to meet the nation’s future energy needs.” The council has responded with eight specific recommendations for developing and implementing advanced coal processing and combustion technologies to satisfy our unquenchable thirst for energy.

-

Coal

Globalization: The new millennium’s "invisible hand"

Participants in the CEO Roundtable at Electric Power 2006 raised a plethora of issues affecting decisions on future electric power generation. Representing a cross section of power producers, the industry leaders made clear that, although globalization has lost its luster in the power generation sector, its impact on the domestic industry remains profound. Ten years […]

-

Coal

Safety still Job No. 1 for PRB users

If coal is to be “America’s energy future” (see p. 42), the work of the Powder River Basin Coal Users’ Group (PRBCUG) will have a lot to do with making it so. Since 1999, the PRBCUG (see sidebar) has fostered the safe, efficient, and cost-effective use of the fuel as it watched its membership swell […]

-

Coal

Cover Story: Coal-fired Electric Power Capacity Continues to Increase

In the U.S. electric power industry, coal is making a comeback as a fuel of choice for new generation projects. During the construction boom that occurred from 1999 to 2003 about 90% of new electric generation utilized natural gas – fired combustion turbines. Unfortunately, over the past few years natural gas supplies have tightened and […]

-

Coal

Editorial: Industrial Perspectives

Is the U.S. supply of coal sufficient to meet the increased demand for coal-fired generation? With the increasing demand for coal to generate electricity, the big question is, How reliable is the supply and transportation of the fuel? Currently, Industrial Info Resources (IIR) is tracking 185 new coal-fired power projects, and if all were to […]

-

O&M

Projects

Kansas City Power & Light Installing SCR at La Cygne Generating Station Kansas City Power & Light (KCP&L), a subsidiary of Great Plains Energy, has awarded The Babcock & Wilcox Company (B&W) a contract for the installation of new emissions control equipment on Unit 1 at its La Cygne Generating Station. When completed, the selective […]

-

Coal

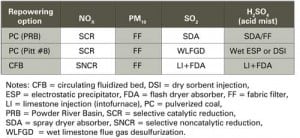

Pollution-Control Technologies: Multi-Pollutant Removal Systems Are a Clean Coal Technology

The first power plants were built about 130 years ago. Coal was then, and is still today, the major fuel used for power generation. Currently, about 1,400 pulverized coal – fired units, with an average age of more than 30 years, generate over 50% of U.S. electric power. The use of low-sulfur coal and improved […]

-

O&M

Project Planning: Repowering or Replacement: What Is the Solution?

Between 1998 and 2002 the U.S. experienced an unprecedented power plant construction boom that consisted mostly of gas-fired, combustion turbine – based power plants. This surge in power plant construction had several driving forces, including electric power deregulation, the emergence of non-utility power producers, a sustained period of plentiful and inexpensive natural gas, and the […]

-

Coal

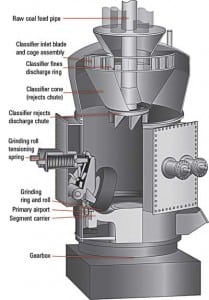

Case Histories: Pulverizer Upgrades Are Reducing Fuel Costs

St. Johns River Power Park (SJRPP) is a two-boiler, 2 x 660-MW station jointly owned by JEA (formerly Jacksonville Electric Authority) and Florida Power & Light (FPL). JEA is the plant operator. The Foster Wheeler boilers went into commercial operation in 1987 and 1988. Each boiler has seven OEM vertical spindle pulverizers (mills) and 28 […]