-

Coal

How accurate are your reported emissions measurements?

Complying with permitted emissions limits may be the most significant operations risk for a power plant. As limits are slowly ratcheted downward, understanding the accuracy and variation of measured pollutant levels becomes even more important. To avoid misunderstandings, regulators and plant owners should factor measurement uncertainty into air quality permit numbers both as the permit is formulated and preceding any subsequent modifications.

-

Business

Mandatory reliability rules are coming. Are you ready to comply?

An extremely reliable North American bulk power system—one that consistently delivers uninterrupted power to every user—is not a dream that must be made reality. To a large extent, that is what we have today. With the exception of infrequent (and therefore, newsworthy) outages, the system has never been more dependable. Nevertheless, with the great northeast blackout of August 14, 2003, still fresh in memory, Congress saw fit to include electric reliability measures in the Energy Policy Act of 2005.

-

Instrumentation & Controls

Cleaning and inspection of stainless steels and nickel alloys for FGD service

Stainless steels and nickel alloys of the C-family are major materials of construction for flue gas desulfurization systems. Both types of materials depend upon the presence of thin, passive, chromium-rich, surface-oxide films to provide the desired corrosion resistance. Corrosion resistance is optimized by proper cleaning before and after fabrication. Here are some guidelines for keeping those materials clean.

-

Marmaduke

Marmy’s medicine show

Steve Elonka began chronicling the exploits of Marmaduke Surfaceblow—a six-foot-four marine engineer with a steel brush mustache and a foghorn voice—in POWER in 1948, when Marmy raised the wooden mast of the SS Asia Sun with the help of two cobras and a case of Sandpaper Gin. Marmy’s simple solutions to seemingly intractable plant problems remain timeless.

-

Commentary

Combating climate change

The overriding environmental challenge of our time is climate change. The problem originates from the emission of greenhouse gases, primarily carbon dioxide, mainly from the transport and energy sectors. If humanity fails to come to terms with this problem, we will be forced to make dramatic changes in the way we live our lives, but […]

-

News

National pastime

—Dr. Robert Peltier, PE Editor-in-Chief During every summer hot enough to break peak demand records, the rhetoric heats up as well, with calls to rid the U.S. bulk-power system of bottlenecks. As the eternal optimist, I see large transmission projects showing signs of life and grid reliability improving. But not everyone is happy about that. […]

-

Coal

Global Monitor (September 2006)

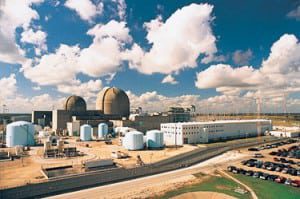

Demand records fall nationwide;

GE’s ABWR to be STP’s edge; Entergy buys Palisades plant; Dithering over desert disposal; Tourist trash-to-energy plant;

Brooklyn says "Yo!" to microturbines; POWER digest -

O&M

Focus on O&M (September 2006)

Level measurement in harsh environment;

Designing insulation for structures;

Shockingly clean boiler

-

Legal & Regulatory

Renewable contracts merit longer terms

The length of term allowed for power sales contracts is a critical determinant of the ability of states to meet their increasingly ambitious renewable power targets. Many utilities advocate limiting terms to 10 or perhaps 15 years for renewable energy contracts, emphasizing the "flexibility" that shorter terms offer. In contrast, contract terms of 20 or […]

-

Coal

Tri-State Generation and Transmission Association’s Springerville Unit 3 earns POWER’s highest honor

It’s said that pioneers take the arrows. In the case of Springerville Unit 3—a 418-MW (net) expansion of a Tucson Electric Power facility in Arizona and the first pulverized coal–fired unit built in the U.S. in more than a decade—the arrows were many. Although Tri-State (the developer), Tucson Electric (the host), and Bechtel Power (the EPC contractor) were wounded by delayed deliveries of major equipment, bankruptcy of a major supplier, and a labor shortage, the companies showed their pioneering spirit and completed the project ahead of schedule. For ushering in a new generation of clean and desperately needed baseload capacity, Springerville Unit 3 is POWER magazine’s 2006 Plant of the Year.

Search