In a rapidly changing energy market, the competitiveness of any power producer increasingly depends upon the reliability, efficiency, and flexibility of its power plants. As the share of renewable energy sources continues to grow, fast-starting capabilities are essential for balancing the system. One multi-fuel engine is uniquely designed to meet these requirements.

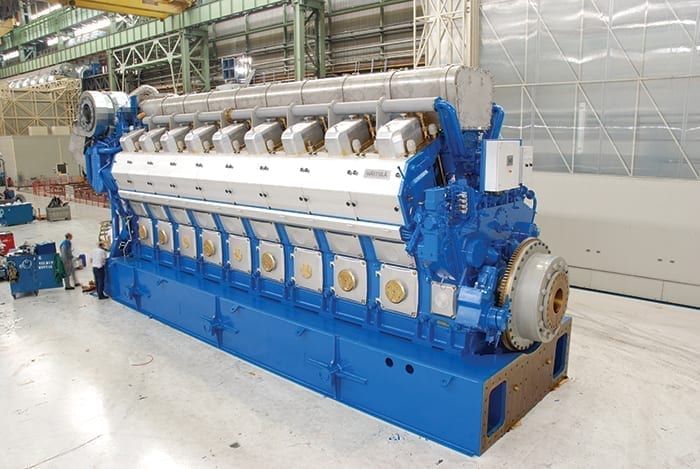

When the diesel version of the Wärtsilä 31 engine was introduced in 2015, it was quickly recognized by Guinness World Records as the world’s most efficient four-stroke diesel engine. Since then, a family of Wärtsilä 31 engines has been developed, all featuring the signature benefit of extremely high efficiency.

|

|

1. The Wärtsilä 31 engine was recognized as the world’s most efficient four-stroke diesel engine, and thanks to its flexibility it can also run on renewable synthetic fuels of the future. Courtesy: Wärtsilä |

The multi-fuel version of this family, the Wärtsilä 31DF (Figure 1), was introduced to the energy market in 2019 with a 20-cylinder configuration, delivering an output of 12 MW per unit. The engine is now available in 12V, 16V, and 20V configurations with output from 7 MW to 12 MW.

With its capability to operate on different fuel types, the Wärtsilä 31DF provides energy security in the event of issues caused by natural disasters, or problems with the logistics, politics, or price of fuel supplies. Its fuel flexibility is also clearly advantageous in situations where a gas supply is anticipated but not yet available. The engine can run on conventional fuel oil until such time as the gas comes online, and the switch from one fuel to another is seamless and instant.

Jukka Lehtonen, head of technology and product management at Wärtsilä, is clearly enthusiastic about the prospects for the 31DF in energy market applications. “The market in general is undergoing a rapid adjustment to a shifting paradigm. Environmental considerations mean that power generation is now increasingly being distributed across a number of different energy sources, with wind and solar rapidly becoming viable as their cost continues to fall. At the same time, operational efficiency, leading to lower fuel and lifecycle costs, has never been as important to the industry as it is today. The market is, therefore, in need of high efficiency as well as flexibility in both fuel choice and operational performance, which is why the Wärtsilä 31DF has been introduced at absolutely the right time,” he said.

Enabling Renewables

Renewable energy sources such as solar and wind are inherently variable in their supply reliability. When the sun stops shining and the wind stops blowing, the level of supply obviously drops accordingly. This creates an imbalance within the system that needs to be compensated for. Conventional baseload plants are not designed to react quickly enough to cope with the variability in supply that is inevitable with renewables.

Fast starting and stopping of the generating set is required to ensure the stability and reliability of the power system, and the Wärtsilä 31DF engine provides just that. Among the outstanding features are its dynamic capabilities, fast loading and unloading, and its ability to be started extremely quickly, synchronizing with the grid within 30 seconds and reaching full output in two minutes from the start command. This makes the Wärtsilä engine ideally suited for modern systems where the greater integration of renewables is required, and where there is a need to deliver an environmentally sustainable and highly efficient energy supply.

“I can’t over emphasize the value that the Wärtsilä 31DF brings to power providers,” Lehtonen said. “Apart from its fuel flexibility, the engine has the flexibility to be used for load following, balancing, and baseload. In all cases, the level of efficiency is outstanding, which in turn, of course, lowers the overall operating costs.”

Bringing Reliability to Island and Isolated Power Systems

For remotely located islands with isolated power systems operating independently of the countrywide electricity network, reliability can be a challenge and blackouts can and do occur, often too frequently. This can affect economic growth—especially in tourist-reliant economies—it can hinder industrial development, and it causes inconvenience for resident populations. Fuel supplies to such locations can also be subject to unpredictable interruptions, thus making the option to be able to switch to an alternative fuel a huge advantage.

The same challenges are true for off-grid industrial operations such as mining locations. A reliable supply of power is essential to productivity and, therefore, also to the profitability of the operation. When the lights go out and the machinery shuts down, nothing works and nothing is produced.

The Wärtsilä 31DF represents a sensible means for alleviating these risks. Its reliability is extremely high, thanks to its wide load range with high part-load efficiency. The two-stage turbocharger enables more energy to be recovered from the exhaust gases, resulting in significantly enhanced engine efficiency. What’s more, the level of efficiency is retained even in partial-load conditions, and the engine can resist output de-rating when operating in hot and humid ambient conditions.

Not least, the engine’s fuel flexibility is an enormous plus in these situations. If, for example, the engine is set to run on gas and for whatever reason that gas supply is suddenly cut off, it can switch to diesel or heavy fuel oil without any delay or shutdown of the power supply. Similarly, it can be run on liquid fuels until such time as gas becomes available.

Future-Proofing with a Modular Design

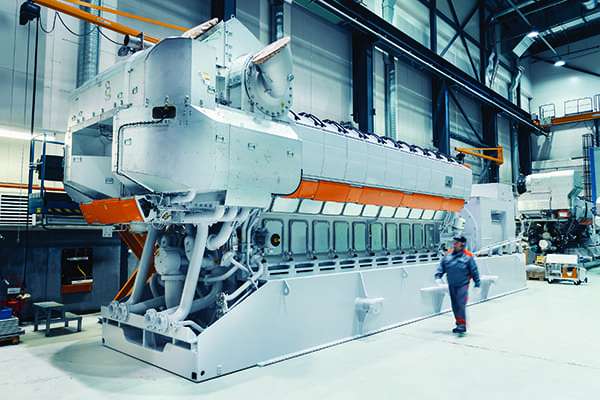

One of the features that makes the Wärtsilä 31 engine family truly state-of-the-art is its modular design (Figure 2). This modularity allows for easy conversions from one fuel type to another, including future fuels such as synthetic renewable fuels. This makes customers ready to adapt to all possible eventualities, regardless of the type of fuel available.

|

|

2. The modular design of the Wärtsilä 31 reduces time spent on maintenance. The shift from single parts to exchange units, such as power units, injectors, and high-pressure fuel pumps, enables easier and more efficient maintenance work. Courtesy: Wärtsilä |

“The beauty of the modular design is that it’s easy to remove a module and replace it with another, without any compromise whatsoever on the power output or efficiency. This is why modularity has been such a central feature of the Wärtsilä 31 product family since day one. What’s more, there is no difference in performance between a product that has been converted and one that was built for purpose from the outset,” said Lehtonen.

Units can be converted one after another while the plant continues operating at full capacity throughout the conversion. Future-proofing minimizes the effect of unforeseen events or changes that may happen down the road. Thanks to the modular design, the Wärtsilä 31DF can be adapted according to evolving requirements, thereby making it absolutely future-proof.

A 100% Renewable Energy Future

The introduction of the 31DF engine for energy market applications is an important next step towards the realization of Wärtsilä’s vision for a 100% renewable energy future. The company’s use of the very latest digital technology is inherent to its engine development work, and the operation of the Wärtsilä 31DF engine can be adjusted online, which is fully in line with the company’s support for online connectivity to its power plant solutions.

With political and social pressure being applied to utilities in the majority of countries around the world, the need to reduce emissions of harmful greenhouse gases is increasing at a fairly rapid pace. There is, therefore, greater interest than ever before in integrating solar and wind power into energy systems. While this has been difficult and not always viable in the past because of the inability of traditional power plants to balance energy input fluctuations, Wärtsilä’s fast-starting engine technology is a key enabler for a clean energy future based on renewables.

Lifecycle Services

Wärtsilä first introduced its dual-fuel engine technology in the 1990s, initially to the maritime industry. The company has since established itself as a global frontrunner in dual-fuel power plant technology, with a broad offering of solutions and unrivalled capacity. Deliveries can range from engine supplies and installation, to full-scale engineering, procurement, and construction (EPC) projects.

Customers can also benefit from Wärtsilä’s complete lifecycle approach, which is aimed at ensuring the performance and competitiveness of the power plant. With a service network with dedicated professionals in some 70 countries around the world, support is seldom far away.

The lifecycle services include everything from comprehensive customized long-term service agreements (Wärtsilä Lifecycle solutions), to product support with parts, field service and technical support, training, and performance optimization including upgrades and conversions.

All of Wärtsilä’s Lifecycle solutions can be customized to specific operating profiles and requirements. The company currently has more than 13 GW of power plant capacity under long-term service agreement. Wärtsilä operating and maintenance agreements deliver, above all, peace of mind to owners knowing that they can concentrate on their core business while the plant is being run at optimal performance, safety, and efficiency.

The Wärtsilä 31 Engine Genset Family

The Wärtsilä 31DF is the latest addition to the Wärtsilä 31 engine genset family, which also includes the original conversion-ready diesel version, and the Wärtsilä 31SG, a spark-ignited pure gas engine generating set that was launched to the energy market in 2017.

As Lehtonen pointed out, “This is a combustion engine offering that represents the accumulation of years of experience and in-house expertise built up over decades. Dedicated research and development work has resulted in a generating set that delivers outstanding efficiency, excellent reliability, and the flexibility in fuel choice and operational performance to meet the needs of power producers well into the future.” ■

—Anders Smeds is product manager, W3X Power Plants, with Wärtsilä.