|

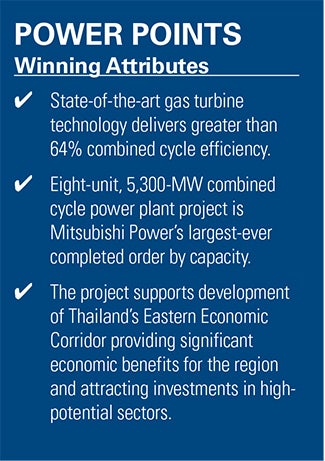

Southeast Asia’s first-ever JAC gas turbines are now supplying power to Thailand’s grid. With efficiency greater than 64%, the eight units deployed—four each at the Sriracha Power Plant in Chonburi and the Pluak Daeng Power Plant in Rayong—are worthy recipients of a POWER Top Plant award.

The Sriracha Power Plant in Chonburi (see opening image) and Pluak Daeng Power Plant in Rayong are two 2,650-MW gas turbine combined cycle (GTCC) power plants owned and operated by a joint venture between Gulf Energy Development Public Co. Ltd. (GULF), one of Thailand’s largest independent power producers, and Mitsui & Co. Ltd., a Japanese trading company. Mitsubishi Power was awarded a full-turnkey engineering, procurement, and construction (EPC) contract in 2018 for the entire 5,300-MW project. The scope covered plant design through commissioning.

“The project was undertaken in support of the development of the Eastern Economic Corridor (EEC)—which encompasses the provinces of Chonburi, Rayong, and Chachoengsao, located southeast of Bangkok—into a special economic promotional zone attracting investments in high-potential sectors such as digital technology, health and wellbeing, smart logistics, and decarbonization,” Mitsubishi Power said. “The Sriracha and Pluak Daeng Power Plants were designed to meet growing demand for electricity as industries and populations grow in the EEC.”

As part of the contract, Mitsubishi Power manufactured and delivered eight M701JAC gas turbines—four for each plant—as well as steam turbines and other ancillary equipment necessary for combined cycle operation. There is also a 25-year long-term service agreement (LTSA) in place for plant maintenance.

The sites are approximately 20 kilometers (12.4 miles) apart and are basically identical. Construction of the power plants progressed in tandem, with the first JAC unit starting commercial operation in the Sriracha Power Plant in March 2021. Subsequent gas turbine units came online at six-month intervals, with the first four in Chonburi from March 2021 to October 2022 and the latter four in Rayong from March 2023 to October 2024.

Mitsubishi Power reports JAC-series gas turbines utilize a high turbine inlet temperature of 1,650C, providing a world-leading power generating efficiency of 64%. One of the most distinctive features of the M701JAC is that it adopts air cooling for combustors instead of steam cooling. This design innovation, combined with an advanced thermal barrier coating on the turbine blades, enables the turbine to achieve high performance while maintaining reliability and reducing complexity compared to steam-cooled systems. The air-cooling system provides a high level of operability including a shorter startup time compared to steam-cooled variants, making the turbine more responsive to grid demands and better suited for flexible power generation operations.

The M701JAC provides lower levels of NOx, CO2, unburned hydrocarbon (UHC), and volatile organic compound (VOC) emissions, making it more environmentally friendly than previous generations of power plants. The JAC series has demonstrated exceptional reliability as well, with units in Thailand exceeding 125,000 actual operating hours, establishing an industry benchmark of reliability for 50-Hz power generation. This milestone represents a significant achievement in the gas turbine industry. These features make the M701JAC particularly well-suited for large-scale combined cycle applications like the Thailand projects, where high efficiency, environmental compliance, and operational flexibility are critical requirements.

Navigating Project Dynamics

There was a maximum of about 2,850 workers on each project during peak activity. To solve the difficulties in finding qualified manpower, Mitsubishi Power hired workers, both locally and from outside of the country, and trained and qualified them in its company-owned education center in Thailand.

Each project achieved 20 million man-hours. “To ensure workplace safety, several activities were implemented, such as establishing a health and safety policy, establishing safety committees at each working level, running regular high-risk work drills, and giving out monthly safety awards,” Mitsubishi Power said.

Project development took place during the COVID-19 pandemic. Border closures and travel restrictions during this period limited the movement of international teams and the transport of goods, including construction and power generation equipment.

“There were difficulties in project execution during COVID-19, but we put in place multiple new measures to recover the schedule,” Mitsubishi Power said. “Remote commissioning, phased resource deployment, and flexible supply chain strategies were deployed to maintain momentum. The team also implemented alternate construction methods and remote installation support to see the project to its timely conclusion.”

|

|

1. The gas turbine combined cycle power plant in Rayong. Courtesy: Mitsubishi Power |

Meanwhile, lessons learned from the earlier-completed Chonburi site were integrated into the Rayong development (Figure 1), enabling smoother installation workflows and faster delivery. “There was a one-team mindset among everyone involved in the project, which was critical for smooth project execution,” Mitsubishi Power reported. In the end, the project was completed on schedule through strong coordination among the teams.

Operational Details

The JAC gas turbines in the two plants are the first such models ever installed in Southeast Asia. The two power plants are each configured with four 1-on-1 single shaft GTCC power trains, each comprising a M701JAC gas turbine, a steam turbine, a heat recovery steam generator (HRSG), and generator. As previously noted, JAC gas turbines are among the most advanced power generation equipment on the market, boasting combined cycle efficiency greater than 64%. Operating them can reduce CO2 emissions by up to 65% compared to standard coal-fired power plants.

As of June 2025, the global fleet of J-Series gas turbines, including the JAC model, has achieved more than 3 million operating hours. The steam turbines used at the Chonburi and Rayong sites are Mitsubishi Power’s TC1F-48 models. Meanwhile, the HRSGs are horizontal, triple-pressure reheat, natural-circulation types manufactured by Nooter Eriksen.

Natural gas is the primary fuel, delivered via Thailand’s existing pipeline network. This includes imported liquefied natural gas (LNG) procured through a long-term gas sale agreement with PTT Public Co. Ltd. and some imported through Gulf LNG Co. Ltd. (GLNG). The generated electricity is sold to the Electricity Generating Authority of Thailand (EGAT) under a 25-year power purchase agreement (PPA).

Since commissioning, operations have been smooth. For instance, by the time the final unit started commercial operation in October 2024, the first seven JAC units had accumulated 100,000 actual operating hours. “The plants have consistently maintained high availability rates, ensuring a reliable energy supply,” Mitsubishi Power said. “In terms of environmental impact, overall emissions have been reduced significantly due to the use of advanced technology.”

The Pluak Daeng facility alone employs approximately 70 staff members. “Around both power plants, various outreach programs, including corporate social responsibility initiatives and volunteering activities, have been conducted—all aimed at effecting positive impact on the surrounding local communities,” Mitsubishi Power said.

In accordance with Thai regulation, noise from the project site reaching neighboring residential areas had to be capped at a maximum of 10 dBA (decibels A-weighted). At the same time, Mitsubishi Power had to ensure that noise reduction measures didn’t impact project timelines and weren’t unsightly. Therefore, it took balanced measures to achieve all of the required objectives.

Ready for Long-Term Performance

Ready for Long-Term Performance

Mitsubishi Power’s remote monitoring system, called TOMONI, was installed at the plants under a long-term service agreement (LTSA). TOMONI is an “intelligent solution that accelerates decarbonization and leverages Mitsubishi Power’s expertise in design, operation, maintenance, and various systems of power plants. It aims to enhance profitability by making energy systems smarter using advanced control functions, artificial intelligence (AI), machine learning, and multi-layered cybersecurity,” the company said.

Meanwhile, Mitsubishi Power said LTSAs afford power plant operators the opportunity to achieve “the highest possible availability, reliability, and performance needed to operate profitably in today’s market. They allow customers to budget and accurately forecast annual maintenance costs on their Mitsubishi Power-manufactured equipment.”

Such agreements enable the provision of both digital and operational flexibility upgrades, rapid service support from Mitsubishi Power’s field team and engineering experts, as well as access to parts inventories in key regional areas. Moreover, reliable planned maintenance coupled with timely upgrades also contribute to continuous enhancement of plant operability.

“We are honored to contribute to Thailand’s energy evolution with the successful delivery of the Sriracha and Pluak Daeng GTCC Power Plants. These state-of-the-art facilities are not only milestones of engineering but also exemplify our commitment to creating a future that works for people and the planet through innovative power generation technology and solutions. As the home of the first-ever JAC units in Southeast Asia, these power plants are paving the way for even greater adoption of high-efficiency natural gas–powered technologies in the region and beyond,” Takao Tsukui, president and CEO of Mitsubishi Power, said.

—Aaron Larson is POWER’s executive editor.