A new technology promises major advantages for coal-fired power plants, steel mills, and other industries that produce flue gases—and it could quell concerns about the increased use of arable land and food prices related to the production of ethanol. That’s because the technology developed by New Zealand–based startup firm LanzaTech uses a proprietary gas fermentation process to convert readily available industrial gases into fuel and chemicals.

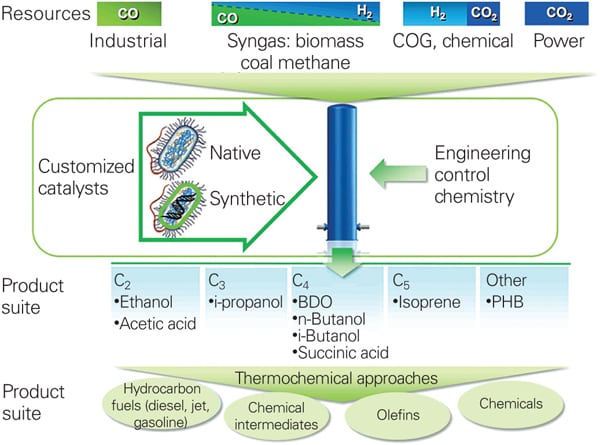

Essentially, the firm’s process promises to convert carbon monoxide–containing gases produced by steel mills, biomass gasification, and coal combustion into fuel and chemical products (Figure 5) using microbes. The process is flexible to the hydrogen content in the input gas and tolerant of typical gas contaminants, says LanzaTech.

|

| 5. From flue to fuel. The LanzaTech process to convert carbon monoxide–containing gases to fuel and chemical products involves sending those gases to the bottom of a bioreactor, where they are dispersed into a liquid medium. This liquid is then consumed by proprietary microbes as the reactor contents move upward in the reactor vessel. After being withdrawn, the net product is sent to the recovery section, which uses a hybrid separation system to recover the valuable product and co-products from the fermentation broth. Courtesy: LanzaTech |

“Because our microbe is feedstock agnostic and completely tolerant to the extreme levels of contaminants found in steel mill and other industrial off gases, our process can use the lowest cost, most readily-available resources, including hydrogen-free gases,” the firm claims.

LanzaTech CEO Dr. Jennifer Holmgren says on the firm’s website that efforts to prove that the fermentation process produces “high-value” chemicals are also paying out. “Those chemicals include the building blocks for the production of polymers and plastics as well as hydrocarbon fuels, like jet fuel, that are compatible with existing fuel stocks and jet engines, so [they] can be ‘dropped in’ to the existing fuel supply,” she said, noting that LanzaTech is working with the U.S. Department of Energy’s (DOE’s) Pacific Northwest National Laboratory on converting some of its chemicals to drop into jet fuel. British airline Virgin Atlantic, which has partnered with LanzaTech, is already committed to begin trials using LanzaTech-produced jet fuel on its Shanghai-New Delhi-London route within a few years. “The biofuels that will succeed must be compatible with existing engines, pipelines and refineries,” Holmgren said.

Auckland-based LanzaTech has been operating a pilot plant at a New Zealand Steel plant since 2008 that it says is capable of generating 16,000 gallons of ethanol made from carbon monoxide a year. Recently, LanzaTech agreed to allow the steel company and its Australian parent company Bluescope Steel to use the technology commercially. Meanwhile, the 2005-founded company has begun building demonstration projects in China, working with major steel manufacturers Baosteel and Capital Steel to turn waste gases into ethanol. The 100,000-gallon demonstration plant to convert waste flue gas at Baosteel is expected to begin production later this year. A full-scale commercial facility—which LanzaTech anticipates will be the “world’s first steel waste to ethanol and chemicals plant”—is planned to be operational by 2013.

Last November, LanzaTech also announced plans to work with Chinese coal producer Yankuang Group to produce fuels and chemicals from synthesis gas produced by gasification. A more recent deal with Indian Oil and Jindal Power and Steel will result in a facility to convert plant gases into ethanol in India.

The company also recently bought the old Range Fuel site in Georgia—a project now renamed “Freedom Pines”—that had been awarded millions in federal funding under the Bush and Obama administrations—to convert regionally sourced waste wood into renewable fuels. It is also working with the DOE, the Defense Advanced Research Projects Agency, and the Federal Aviation Administration to adapt its technology to produce aviation fuels for commercial and military use. Separately, the company is also working with the Chinese Academy of Sciences on research, development, and commercialization of related technologies.

This process to convert flue gases to fuel has garnered much attention from investors. In addition to racking up clean technology accolades (it was Global Cleantech “Company of the Year” for 2011), LanzaTech is being backed by Malaysian national oil company Petronas, Malaysian engineering firm Dialog Group, and investing groups Khosla Ventures and Qiming Venture Partners.

—Sonal Patel is POWER’s senior writer.