The global market for solar photovoltaic (PV) panels shows no signs of slowing down, with cumulative installed capacity expected to reach 700 GW and annual demand to pass 100 GW by 2020, according to GTM Research. This booming market has spurred manufacturers to introduce a variety of innovations intended to increase panel efficiency and reduce manufacturing, installation, and ancillary costs.

South Korean firm LG Electronics introduced a new version of its NeON PV cells at the Solar Power International (SPI) conference in Anaheim, Calif., in mid-September. The NeOn 2 makes several breaks with traditional silicon PV cell design (Figure 1). First, rather than employ the usual two- or three-ribbon approach across the cell to gather the electric charge, the NeON 2 uses an array of 12 wires.

|

| 1. Neon light. LG’s NeON 2 solar photovoltaic cells use an array of narrow wires to gather power across the cell instead of the traditional ribbons. Courtesy: LG Electronics |

LG says this design offers a number of advantages. First, by dividing the current among a larger number of conductors, the electrical loss through each wire is greatly reduced. Second, the use of round wires in place of flat ribbons means light entering the cell is scattered more efficiently and less is reflected out. Finally, because each cell has more conductors, microcracks and other defects that develop in the cell over time have far less effect on output because there are many more paths for the electric current.

In addition, the NeON 2 cells are bifacial, able to absorb light from both sides. This makes them more efficient when sunlight strikes the cells at less-than-ideal angles during morning and evening hours. LG says the 320-W, 60-cell NeON 2 panels are able to generate more power than conventional 72-cell panels and offer up to 3% higher efficiency than the first-generation NeON design.

Though they have garnered far fewer sales and less attention than crystalline silicon PV cells, thin-film copper-indium-gallium-selenide (CIGS) panels have maintained a market niche (around 7% in 2015, according to research firm IHS) because of certain advantages they have over crystalline silicon–based panels, mainly that they are lighter, thinner, more flexible, and have a reduced visual footprint.

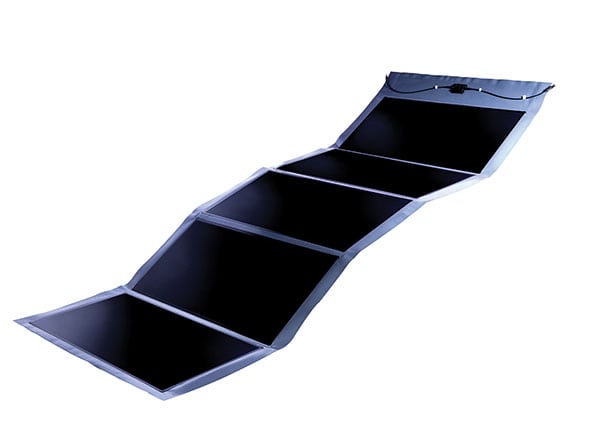

Taiwanese CIGS manufacturer Hulk Energy Technology (Hulket) and Italian firm ENERGYKA Electrosystem debuted a new product at SPI that combines Hulket’s CIGS panels into a flexible multi-panel module (Figure 2). The Prometea modules are available in outputs from 100 watts to 500 W. They are foldable, portable, and can be installed with far less effort and additional equipment than crystalline silicon PV panels.

Finally, San Jose–based Silicor Materials has developed an alternative to traditional polysilicon that is produced through a proprietary metals-based process requiring two-thirds less energy but still achieving conversion efficiencies in line with traditional materials. Silicor announced at SPI that it has secured $105 million in equity capital agreements to support the construction of its first commercial-scale manufacturing operation in Grundartangi, Iceland. The company has already secured sales commitments equal to approximately 75% of the plant’s annual production capacity, it said.

Silicor CEO Terry Jester told POWER that the process is based on traditional aluminum smelting, where silicon is viewed as an impurity. Basing their factory in Iceland—where aluminum smelting is a major industry due to the island’s cheap hydroelectric power—allows them to reduce costs by partnering with local aluminum companies. Unlike traditional silicon production, which relies on hydrochloric acid and trichlorosilane, Silicor’s process requires no toxic chemicals—a major criticism that has been leveled at the solar PV industry as its footprint has grown. Jester said Silicor expects to break ground on the factory next year and begin production in 2018.

—Thomas W. Overton, JD, associate editor