The U.S. should dramatically expand the scale and scope for utility-scale commercial viability demonstrations of retrofitting or rebuilding existing coal plants with carbon-capture technology—and support aggressive research on reducing the technology’s cost—if global efforts to contain climate change are to succeed, a new report by the Massachusetts Institute of Technology (MIT) Energy Initiative concludes.

The report, released in June and based on the findings of a recent MIT Energy Initiative (MITEI) symposium, says the overall research and demonstration effort should be aimed at sharply reducing the cost of carbon capture technology, currently estimated to be in the range of $50 to $70 per metric ton of carbon dioxide (CO2), to make it more attractive for China and other rapidly developing countries seeking to fuel their economic growth with new coal-fired generation.

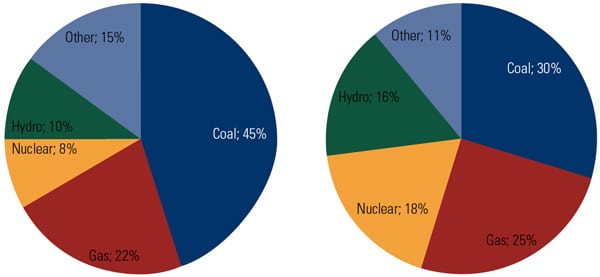

Coal-fired power plants account for more than a third of U.S. CO2 emissions—more than 2 billion metric tons annually—while China’s coal-powered fleet emits twice that amount and is on track to reach 10 billion metric tons annually by 2030. China and the U.S. account for 40% of global CO2 emissions and more than half of the world’s coal consumption.

About half of U.S. electricity comes from coal-fired power plants that average 35 years of age, while China in the last five years has brought online coal-fired generation capacity about equal to the total installed capacity in the U.S., the report noted. Both countries have abundant supplies of coal.

This extreme coal dependence by China and the U.S. makes finding a cost-effective solution for carbon-capture retrofit imperative, said MIT professor and MITEI Director Ernest Moniz, the report’s principal author.

“There is no credible pathway towards prudent greenhouse gas stabilization targets without CO2 emissions reduction from existing coal power plants,” Moniz said at a June 19 press conference. “We urgently need technology options for these plants and policies that incentivize implementation. We may not see a strong CO2 price signal for many years. In the interim, we need a large, focused federal program to develop and demonstrate commercial-scale technologies.”

Reducing the cost of the technology is particularly important for China, said Entergy Corp. Chief Executive Officer Wayne Leonard, who with Moniz co-chaired the MITEI symposium.

“It would be very expensive for the U.S. to reduce CO2 emissions by shutting its existing coal plants down and replacing them with anything else,” Leonard said. “It will be prohibitively expensive for China and the developing world to shut down their coal plants and replace them. We should not count on them doing so.”

Leonard said prospects for meeting the challenge of global warming are “bleak” without a cost-effective carbon-capture solution for existing coal plants.

“I am genuinely concerned that without technology to address CO2 emissions from existing coal plants, even if we pass cap-and-trade legislation, our prospects for accomplishing what we set out to achieve—real worldwide emission reduction goals—are bleak,” he said. “Our approach to climate change in this country must pass what we call ‘the China test’: We must develop solutions that work for them.”

Moniz noted that the price of controlling sulfur dioxide emissions from power plants fell by 50% in the two decades following the 1990 enactment of the Clean Air Act Amendments, as scientists found new ways to “scrub” the pollutant and engineers gained experience in installing SO2 scrubbers. The cost of building and installing scrubbers on average fell 11% for every doubling of the number of installations, he said.

A cost of $60 per ton for capturing CO2 “does not sound like an incentive for China to start doing a lot of large-scale carbon capture,” Moniz said. “Suppose we were to take $25 per ton off that price. That’s a hundred billion dollars a year—that’s a big deal in terms of moving things forward.”

Moniz noted that the third round of the Energy Department’s Clean Coal Power Initiative includes retrofit technology among the list of technologies eligible for funding under that program. However, he said this initiative has neither sufficient funds nor project management resources to support the large-scale projects recommended by the report.

He also said that DOE’s carbon capture and sequestration program must be expanded to include projects at existing plants.

The report stressed the need for a fleetwide, detailed inventory of plants and sites to determine which plants are suitable for retrofitting, rebuilding, or repowering or for partial CO2-capture solutions tailored to a plant’s particular configuration. The inventory should include whether plants have access to additional water supplies necessary for certain technologies; retrofit space constraints; proximity to suitable carbon storage sites and/or CO2 pipelines; and other factors.

While the main post-combustion retrofit technology involves chilled ammonia, Moniz emphasized that research is well under way on a host of other technologies.

“We are seeing in universities and labs a huge number of ideas that span relatively straightforward but new kinds of solvents to completely radical kinds of new technologies that hold possibility of cost reduction,” Moniz said. “We have to go there, and go there aggressively, and one of the messages is that we don’t believe the federal-supported research program has anything near the scope and scale to aggressively address these kinds of breakthrough technologies.”

—Chris Holly (cholly@accessintel.com) is a reporter for COAL POWER’s sister publication, The Energy Daily.