Whether it’s market forces or other factors leading to a change in operating mode, going from baseload to flexible operation places substantial new stresses on a plant and its staff. Knowing what you’re getting into is key to successfully managing the transition.

With the growing need for operational flexibility across the power industry, the combined-cycle gas turbine (CCGT) fleet is increasingly being subjected to load-following and cyclic operation. This change in operating mode is introducing new types and higher rates of damage and can result in reduced performance and increased operation and maintenance (O&M) and repair costs. To meet these challenges, today’s fleet is taking strategic and tactical measures, and the Electric Power Research Institute (EPRI) is compiling information on effective approaches and best practices.

Changing Landscape

Over the past decade, the pattern of duty modes and plant dispatch of CCGT plants has changed. This change involves a general shift for CCGT plants from baseload to flexible operation with increased frequency and level of cycling of these plants.

Flexible operation is broadly defined as any mode of operation other than baseload, and includes several specific types of duty modes. Two-shifting is starting up and shutting down a plant each day to meet load demand during periods of high demand. Double two-shifting is starting up and shutting down a unit twice a day to match the early morning and evening peaks in load demand. Load following is operating online for more than 48 hours, with varying load throughout the day as demand changes. Many times these plants turn down to some minimum load when demand is low.

Whatever the duty mode, flexible operation typically involves more frequent startups, more rapid ramping, low load operation, and more frequent shutdowns or layup.

Factors contributing to this trend include reduced overall demand following the economic recession, competition, changes in fuel prices, aging plants, demand for a more reliable power grid, and stricter environmental controls. In some regions, one key factor is the increasing deployment of intermittent renewable generation, such as solar and wind, which is dispatched as “must-take” and forces fossil plants to provide load-balancing services. In this context, relatively small differences in costs and reliability can make a large difference in station ranking, leading to many older, less-efficient CCGT plants being required to load follow.

Effects of Flexible Operation

CCGT plants have less operating flexibility than conventional steam plants, which can be run down to 40% of rated output, while CCGT plants have difficulty in getting below 60%. A further problem is the length of time that it takes for the heat recovery steam generator (HRSG) plant to achieve full output. Hence, although a CCGT plant may be able to produce power relatively quickly, it is not really suitable for load-following until some time after startup.

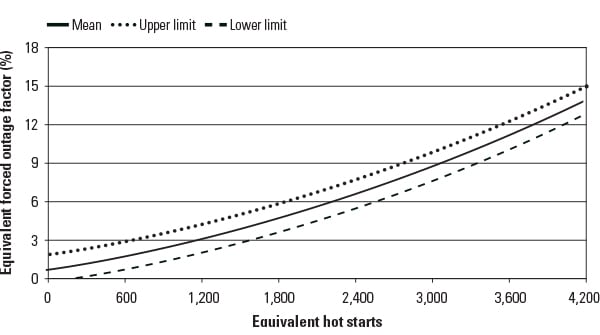

EPRI research has identified a number of common damage mechanisms related to cycling. Cycling load is associated with stresses from varying temperatures and pressures, which can trigger fatigue and fatigue-related damage mechanisms.

Thermal Fatigue. The most common problem resulting from cycling is thermal fatigue damage, which manifests itself in the form of material deformation, cracking of individual components, or mechanical failure of structures. This mechanism is caused by the large temperature swings associated with flexible operation.

Thermal Mechanical Fatigue. This mechanism, which occurs in rotating components such as turbine blades, vanes, and other hot-section components, is caused by thermal expansion and contraction, reinforced by mechanical strains associated with centrifugal and torsional loads.

Differential Thermal Expansion. This damage occurs when components undergo high thermal growth relative to surrounding components. This mechanism can affect combustor cans, boilers, and HRSGs.

Corrosion. Two-shifting or any other operation that challenges the ability of the plant to maintain water chemistry can lead to increased corrosion and accelerated component failure. This mechanism can manifest itself as increased problems with corrosion-fatigue of economizer tubing and stress corrosion in steam turbines (STs).

Impaired Performance of Environmental Control Equipment. Load following and other modes of flexible operation can affect the performance of selective catalytic reduction (SCR) systems.

Figure 1 shows the types of potential cycling-related damage that might be expected in different areas of a CCGT plant.

|

| 1. Wide range of challenges. This graphic details the many areas of potential cycling damage in a combined-cycle plant. Courtesy: EPRI |

What are the consequences of this damage? Recent investigations found that a change from baseload operation to operating under cycling conditions can result in increased capital spending for component replacement, increased routine O&M costs due to equipment wear-and-tear, lower availability due to higher failure rates and outage times, and higher fuel consumption due to operating in less than an optimal manner (more stops and starts and more load changes), negatively affecting unit heat rate. Also, when a unit is subjected to cyclic operation, reliability can suffer. These consequences can lead to a unit becoming less reliable and more expensive to operate, resulting in a lower dispatch order and increased need for additional flexibility, effectively creating a spiral of cycling operation leading to more cyclic operation.

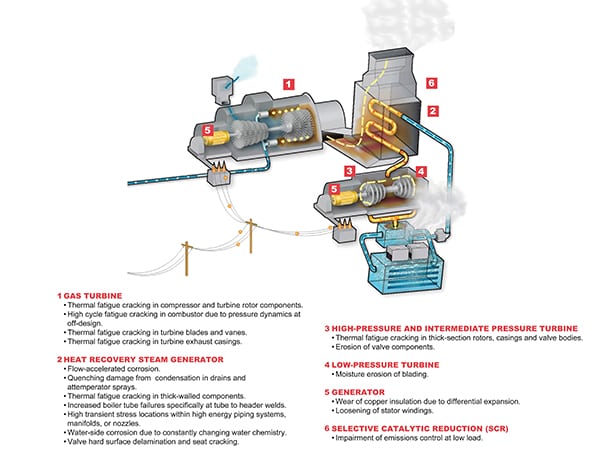

In 2013, an EPRI study investigated the impact of cycling on the O&M costs of CCGTs with capacities of 110 MW to 492 MW. The results showed that the strongest indicator of annual O&M costs was the number of equivalent hot starts (EHS) that a unit performs. The study assumed a hot start equals 1 EHS, a warm start equals 3 EHS, and a cold start equals 5 EHS.

The same study explored the equivalent forced outage factor (EFOF) for CCGT plants operating in both baseload and cycling modes. EFOF is the fraction of a given operation period in which a unit or a train is not available due to forced outages. This particular parameter is very useful in measuring forced outages in cycling power plants, because it takes into account the derating hours.

Findings showed that the average EFOF value for CCGT plants operating in the cycling regime is about 3% higher than the plants operating in the baseload mode in the first six years of operation and about 1.5% higher between six to 20 years of operation. EFOF for cycling plants increases much more abruptly between 20 and 30 years of operation compared with baseload plants. Figure 2 shows the average EFOF versus lifetime EHS for CCGT plants operating in cycling regimes.

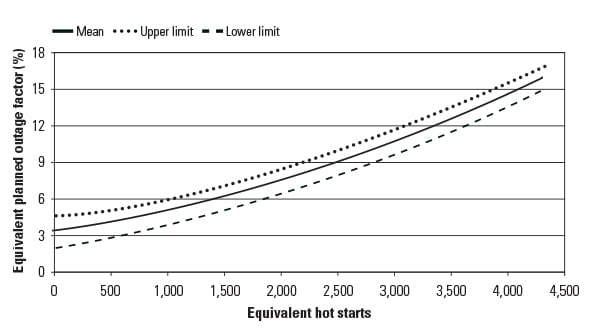

The study also looked at the equivalent planned outage factor (EPOF) for CCGT plants operating in baseload and cycling modes. Planned outages normally refer to the removal of a unit from service to perform work on specific components that is scheduled well in advance and has a predetermined duration, such as annual overhaul, inspection, and component testing.

In general, increased routine maintenance is required due to increased levels of wear-and-tear when a plant moves from baseload operation to cyclic mode. Results showed the planned outage levels for cycling CCGT plants are within about 6% to 9% during the first six years of operation and within about 4% to 6% for the next 14 years of operation. The EPOF achieves its minimum level between 10 and 14 years. During the “major component wear-out period,” which is near the end of life (assuming major components at or near end-of-life have not been replaced), the EPOF value for cycling CCGT plants increases to about 15% to 18%. Figure 3 shows the average EPOF versus lifetime EHS for CCGT plants operating in cycling regimes.

|

| 3. Planned outages increase. This chart shows average equivalent planned outage factor vs. lifetime equivalent hot starts for CCGT plants operating in cycling regimes. Source: EPRI |

Another recent EPRI study documented 23 cases in which major HRSG components unexpectedly reached end-of-life. Many of these failures can be attributed to more frequent cyclic operation than originally anticipated in the plant design. For components to have a full design life, the factors anticipated by the designer need to be similar to those actually experienced by the plant components in service. These factors include the operating temperature and pressure conditions, temperature rates of change, external stresses imposed by support systems, and corrosion rates. If one or more of these variables differs from values anticipated by the designer, a premature failure can occur.

Examples of documented cases of premature failures included weld failures in high-pressure steam flow nozzles, catastrophic leakage of high-pressure drum manway closures, turbine steam lead drainpipe failures, parallel slide-gate valve failures, ST bypass desuperheaters, lateral wye failures, freeze damage, duct burner-related damage, and superheater and reheater tube buckling.

Mitigation Measures: Operations

In recent years, EPRI has conducted several studies to better understand how CCGT plants are responding to changing operating conditions. The following is a sampling of lessons learned from the studies.

Culture Change. An important factor for success in transitioning from baseload to cycling operation is the unit management’s understanding that a culture change is necessary at the site. This change has to begin with unit management, and the changes will need to be communicated to and understood by unit staff. This transition will require leaders who are willing to make tough choices, have excellent communication skills, and have the ability to help people in the plant understand the reasons for the change and its impact on the company, plant, and staff.

Four elements of plant culture, when implemented, can properly aid in the transition from baseload to cycling operation: (1) a change management plan, which provides a step-by-step plan for guiding any change; (2) a communication plan for informing staff of changes; (3) personnel involvement, for engaging personnel in the changing operations; and (4) human performance improvement, for providing training in new procedures and avoiding human errors.

One priority for a cycling unit that once was a baseload unit is to keep people focused on having the unit ready when it is called to operate. Staff must feel a sense of urgency about their new operating role. The key to success will be keeping people focused on a day-to-day basis and ensuring a clear understanding of the goals of a cycling plant.

Mike Woodhouse, who managed ScottishPower’s Rye House Power Station, a 700-MW CCGT plant in Hertfordshire, England, that shifted from baseload to cycling operation due to market conditions, describes the importance of plant culture this way: “Our plant was fairly robust to begin with, so the physical changes to the plant were pretty minimal. The majority of it, the key thing, was the people—developing optimized operating procedures and training the staff in them.”

Flexible Operations/Optimization Trials. Prior to embarking on full flexible operations, the plant management team should plan a series of flexible operation/optimization trials. Following the trials, a flexible operations procedure should be written that captures best practices developed during the process.

According to Woodhouse, this is a critical part of planning. “As part of our upfront planning, we conducted trials so that operators could get used to starting and stopping the plant. The data from those trials was used to help us understand what was working and what needed to be changed.”

Operations Procedures. For plants transitioning from baseload duty, existing operational procedures will typically be biased toward steady-state operations and will require a review as part of the planning phase for flexible operations. Two shift–related operational procedures should be reviewed and updated. Following the flexible operations trials, site operational procedures will need to be updated to reflect the lessons learned and best practices developed. New considerations that should be incorporated into updated cycling procedures include changes to setpoints, normal operating bands, and ramp rates.

Startup and Shutdown. For a baseload plant, startup and load following are historically not given a great deal of management attention, because the few starts that do occur are usually following overhaul periods where intrusive work has been undertaken that will introduce reliability issues, such as interlocks not set and valve open/close limits being out of calibration. For a plant to operate in a flexible mode, reliability issues must be addressed in a more systematic approach, with the emphasis on continual improvement derived from teams responsible for various areas of plant reliability.

Generally, if startup reliability is effectively managed, shutdowns will also be reliable because the same components (for example, GT gas valves/boiler feed and steam valves) are used. However, emphasis should be on measuring trips from low load while shutting down; these steps can often be overlooked in the high operations workload of a shutdown.

Review of startups and shutdowns may highlight needed changes. “In plant trials, we learned that the control system needed to be improved,” says Woodhouse. “When the plant was operating in baseload, if the control system didn’t work optimally at startup, it was not a priority. But for flexible operation, we had to make changes to allow smoother and faster starts.”

Staffing Levels. Staffing levels for baseloaded plants are typically based on steady-state operation, where minimal operator intervention is expected. Introduction of flexible operations will change the responsibilities and time commitments at different staff positions. Flexible operations trials can help to identify the needed changes in staff levels.

“When the plant was a baseload plant, our operations staff took responsibility for some maintenance activities,” says Woodhouse. “In that regime, once the plant was up and running, the operating workload diminished. But under cycling, the operations staff no longer had time for maintenance tasks, so we had to enlarge and strengthen our maintenance team.”

Staff Training. The changing skill requirements of flexible plant operation will require a review of the plant operations training process. Consideration should be given to the following: (1) increasing the knowledge in CCGT thermodynamics to support the operators’ decision-making in startup/shutdown scenarios; and (2) sourcing CCGT simulator training when diagnosing sequence faults and managing transients (for example, high or low drum level can be undertaken). A training program should be implemented to develop two-shift operation skills, and a method should be put in place to share lessons learned from shift to shift.

Continuous Improvement Process. An effective approach for plants transitioning from baseload to flexible operation is implementing a continuous improvement process. This technique involves identifying and analyzing failures on a continuous basis and using that information to make changes in procedures to avoid future failures. When put in place over time, these continual improvements result in significant overall gains in the major business metrics such as production cost, reliability, quality, and lead time.

“Once you’re under way in flexible operations, it’s important to learn as you go,” says Woodhouse. “Our continuous improvement program gave us a structure to analyze every failure to start and every drop in load, to find a solution, and to feed that solution back into the processes.”

Monitoring. As the plant enters an operational state not previously experienced, a review should be undertaken of the operational team’s plant inspections. For example, plant items that will now be cycled frequently (feedwater valves, fuel gas control valves, and boiler casings, for example) will be more vulnerable to performance deterioration.

“We found we had to do more frequent inspections,” says Woodhouse. “We were able to reduce their rate as we got more mature. But initially we did inspections of the gas turbines and boilers every three months. The biggest issue we found was thermal cycling-induced cracks in the GT outlet ducts, which meant we had to go in every three months and complete inspections and weld repairs in the ducts.”

Minimum Stable Generation (MSG). Depending on an individual plant’s commercial characteristics, achieving a low MSG may be preferable to completely starting or stopping the plant, when plant damage costs and the risk of failure to start are taken into account. Reducing a plant’s MSG can be achieved by the same management strategy as optimizing flexible operation; indeed, a move to a low MSG is usually the first option as a plant’s efficiency starts to dictate minimized generation over loss-making periods, such as overnight.

Plant Preservation (Layup). A strategy document and operations procedures should be developed for plant preservation during layups of different duration. (See “Layup Practices for Fossil Plants” in the February 2013 issue, online at www.powermag.com.)

Increased Levels of Automation. The levels of plant automation should be reviewed before the start of flexible operation trials to ensure that the existing automation is functioning to design and to identify any potential improvements. During the review, consideration should be given to the increased operator intervention required during the startup and shutdown plant phases of operation to ensure that the operators can maintain an overview of the process at all times.

Mitigation Measures: Maintenance

Frequent cycling also impacts maintanence practices, and changes need to be made to adapt to the added stresses placed on the plant.

Maintenance Team Structure. If the team structure is unchanged from baseload operation, that structure will not reflect the new maintenance team challenges under the flexible operating regime. The site maintenance manager needs to produce a new team structure capable of delivering the revised maintenance requirements.

Time-Based Equipment Inspections. The maintenance regime of a baseload plant may use time-based equipment inspections extracted from original equipment manufacturer (OEM) manuals. The existing routine time-determined tasks in the maintenance management system should be reviewed. Where possible, the regime should be moved to condition-based maintenance inspections, thereby reducing the frequency of intrusive, major inspections. In addition, the preventive maintenance basis should be reviewed as new stressors and failure mechanisms have been introduced.

Changing Maintenance Strategies. Each GT and heat recovery boiler design will have differing responses to the effects of flexible operation. The OEM should be consulted for any design-related issues that will form a boundary for flexible operation. For example, an OEM will have a limit on the number of starts or equivalent operating hours (EOHs) between inspections. A commercial decision will need to be made either to restrict the number of plant starts to stay within the current inspection regime or to operate starts unconstrained and flex the timing of GT inspections.

HRSG: GT Exhaust Duct Cracking. The exhaust gas duct from the GT to the first flexible expansion joint is at risk of stress-induced cracking, particularly in welded areas. The internal surface and external cladding of the duct should be regularly inspected during GT outages. Damage should be ground out and repaired during a scheduled outage.

GT: Accelerated Degradation of Hot Gas Path (HGP) Components. HGP components may fail before reaching the designed EOH limit. These components should be monitored during inspections. The OEM should be consulted to design flexible, operation-resistant components.

ST: Thick-Section Cracking. Thermal stresses develop due to a mismatch between the temperature of the admitted steam and the metal in the first-stage region of the turbine. These high stresses can initiate and propagate cracks in the inner and outer casings and rotors. Possible measures include following the OEM’s recommended starting and loading procedures, installing steam bypass systems, and installing thermocouples to monitor critical temperatures and temperature differentials during starting, loading, and unloading.

Instrumentation and Controls: Alarm Systems. If the alarm system is not carefully managed, operators can be deluged with low-priority alarms and status change messages when the plant is at its most dynamic on startups and shutdowns. Alarm management should be reviewed to incorporate findings from the flexible operation trials. A plan should be created to eliminate unactionable alarms, bad actors, and alarm floods to properly manage plant status changes. (See “How to Avoid Alarm Overload with Centralized Alarm Management” in the February 2010 issue, online at www.powermag.com.)

What are the chief lessons for plants changing their operating profiles? Woodhouse sees two main messages. “One big learning point is that preparation and planning are key. Do as much as you can upfront before you commercially start flexible operations. Don’t expect to blindly go into it and see what happens. Once you get into it, you’ll have more than enough facing you day to day. The other learning point is that after you’re under way, you want to have some kind of continuous improvement process in place because you’ll be faced with a lot of issues, and unless you’ve got a process to capture and manage them all, you can get overwhelmed.”

Future EPRI Research

In 2014, EPRI is planning several research studies to assist combined-cycle plants in operating more efficiently and avoiding damage under conditions of operating flexibility.

One project in 2014 will help plants design a systematic approach to reducing minimum load for coal-fired units, with a combined-cycle plant project to follow in 2015. The project will use lessons from plants that have successfully achieved minimum loads as part of EPRI’s ongoing Operational Flexibility Implementation Case Studies. The project will include a web-based tool to aid in operational tests necessary to achieve a lower minimum load.

Another project will develop an integrated, holistic procedure for plant layup (2014) and provide a web-based tool (2015) that guides a unit through the critical steps for plant layup.

The authors wish to acknowledge Mike Woodhouse (mjwpower@gmail.com), who served as operations, engineering, and plant manager at Rye House Power Station in Hertfordshire, England, for 14 years. ■

— Neva Espinoza (nfox@epri.com) is manager of the Operations Management and Technology Program, Bill Carson (bcarson@epri.com) is manager of the HRSG Dependability Program, and Rick Roberts (rroberts@epri.com) is senior technical specialist, all at EPRI.