|

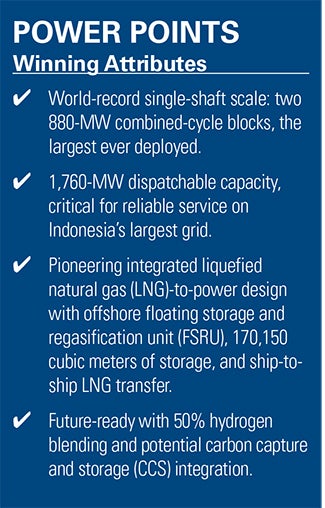

Indonesia’s 1,760-MW Jawa Satu pairs world-record single-shaft scale with liquefied natural gas–to-power integration. A POWER Top Plant winner, it reinforces reliability for the nation’s most critical grid while advancing future-ready decarbonization goals.

Stretching across more than 17,500 islands, Indonesia straddles the equator as one of the world’s largest archipelagos and a crucial player in global energy markets. But, despite being endowed with vast fossil fuel reserves, the country only a decade ago faced an energy crisis that demanded radical intervention. Faced with explosive electricity demand growth—driven by rapid economic expansion across Java Island, the nation’s economic center—and chronic infrastructure shortfalls, by 2014, the country struggled to contain rolling blackouts, negative reserve margins across most regional grids, and an electrification rate that left more than 30 million Indonesians without access to reliable power. Particularly hard-hit was the Java, Madura, and Bali (JAMALI) electrical system, representing Indonesia’s largest power network serving 160 million people and controlling 79% of the nation’s generator capacity.

In 2015, PLN, Indonesia’s state-owned utility company, responded by launching an ambitious 35-GW electrification program that targeted electricity demand growth projected at 8.7% annually through 2019. The program aimed to achieve a 97.35% electrification ratio by 2019. The strategic framework scaffolded the development of several mega-projects. Among the largest of these was the Jawa Satu (or Jawa 1) facility, a 1,760-MW liquefied natural gas (LNG)-to-power project spearheaded by PT Jawa Satu Power, a special-purpose company, formed by a consortium led by Indonesia’s state energy company, Pertamina New & Renewable Energy, Japan’s Marubeni Corp. and Sojitz Corp.

From its outset, the project was engineered to fill a crucial dispatchable power gap with reliable, flexible power. But since Jawa Satu’s commissioning in March 2024, the facility—one of Southeast Asia’s biggest gas-fired plants—has played a substantive role in ensuring a sustainable transition for Indonesia. Even as Indonesia today grapples with oversupply from the 35-GW program, Jawa Satu’s competitive generation costs within the Jawa-Bali grid provide both economic efficiency and long-term grid stability essential for Indonesia’s continued industrial development and energy security objectives.

Technical Excellence at Unprecedented Scale

Still, getting the massive project built with the urgency it demanded required foresight and perseverance. From the government’s April 2015 decree launching the 35-GW program to Commercial Operation Date (COD) in March 2024, Jawa Satu’s nine-year journey delved into every dimension of large-scale infrastructure delivery—from multi-country financing and engineering, procurement, and construction (EPC) execution—led by GE Vernova—to COVID–19 pandemic-era disruptions.

|

|

1. Jawa Satu’s integrated offshore floating storage and regasification unit (FSRU) is operated by PT Jawa Satu Regas, with ownership divided among Pertamina NRE (26%), Marubeni (20%), Mitsui O.S.K. Lines (MOL, 19%), Sojitz (10%), and Humpuss (25%). Built by Samsung Heavy Industries in South Korea, the FSRU has a storage capacity of 170,150 m³, dimensions of 292.5 meters in length overall and 43.4 meters in breadth, and a regasification capacity of 300 million standard cubic feet per day. Courtesy: MOL Group |

The development cadence is especially remarkable because the project integrates two 880-MW combined cycle blocks in the largest single-shaft configuration ever deployed. The project features two GE Vernova 9HA.02 gas turbines (Figure 1)—each paired with a steam turbine and generator and a GE Vernova Once Through (OT) HRSG. “GE Vernova’s 9HA.02 gas turbines and advanced combined cycle technology were chosen for Jawa Satu due to their industry-leading efficiency, operational flexibility, and scale that lowered CAPEX and OPEX of the power plant,” Jawa Satu Power told POWER.

An important consideration was that partners sought technology that offered faster ramp-up times than coal or diesel units to better suit JAMALI’s load fluctuations. “This flexibility is crucial for maintaining grid stability. Its substantial 1,760 MW capacity also significantly contributes to meeting the region’s expanding electricity needs and lowering the average carbon emission in the grid,” GE Vernova noted.

However, each 880 MW block required seamless integration of gas turbine, steam turbine, and generator on a single shaft, demanding “extremely precise engineering and manufacturing tolerances to manage vibration, thermal expansion, and dynamics at such a large scale,” GE Vernova said. That required designing optimal plant layouts and footprints, “while ensuring efficient construction, operation, and maintenance, often with a reduced footprint compared to multi-shaft configurations.” Beyond that, the massive blocks presented logistical challenges related to transportation and installation of its significant, heavy components.

GE Vernova, notably, also developed sophisticated control systems to manage the complex interactions within the large blocks to secure stable and efficient operation across various load demands. Meanwhile, the plant’s black start capability sets it apart in disaster resilience scenarios, enabling independent startup without external power to re-energize grid sections after complete or partial blackouts, it said.

FSRU Integration Delivers Strategic Advantages

Another distinctive feature is Jawa Satu’s integrated “gas-to-power” approach, which combines power generation facilities with a floating storage and regasification unit (FSRU) that has a cargo capacity of 170,150 m³ and a regasification capacity of 300 million standard cubic feet per day (MMscfd) (Figure 1). Its gas supply, shipped from the Tangguh field in Papua at the eastern tip of Indonesia, addresses the nation’s archipelagic challenge of developing extensive pipeline networks across thousands of islands and offers a flexible alternative to traditional gas infrastructure constraints.

“FSRUs provide on-demand regasification, allowing the plant to respond quickly to changes in gas demand for power generation,” GE Vernova noted. They also require less land than onshore terminals and reduce environmental impacts. “The FSRU installed at Jawa Satu can also perform a ship-to-ship LNG transfer that enables it to be an LNG hub in the region as required,” Jawa Satu Power said. “They can also be installed at a relatively lower cost and in a shorter period compared to onshore LNG receiving terminals, offering flexibility in project deployment.” By storing LNG offshore, the unit “acts as a buffer, ensuring a continuous and secure supply of natural gas to the power plant, even in challenging environments or during potential disruptions to pipeline supply.”

While Indonesia has long developed gas power plants, Jawa Satu’s integrated FSRU-to-power model also adds environmental safeguards. Its closed-loop cooling system recirculates water to reduce overall use and minimize seawater intake. ‘Jawa Satu follows established operational protocols and is regularly monitored to ensure compliance with applicable Indonesian and international environmental and maritime safety standards,’ GE Vernova noted.

Beyond these measures, the plant has been engineered with future decarbonization in mind. Its HA platform operates with fuel flexibility, including hydrogen blending—currently 50% with a roadmap to 100%, according to GE Vernova. In September 2023, GE Vernova, CARBONCO, bp Berau, PLN Nusantara Power, and PT Jawa Satu Power (also known as Jawa 1) signed a memorandum of understanding to pursue one of Indonesia’s first full carbon capture and storage (CCS) value chain studies. A feasibility study evaluated capturing 5.5 million tonnes per annum (MTPA) of CO₂ from Jawa Satu and another Jakarta-area power station, transporting it over 3,000 kilometers for sequestration at bp’s Tangguh field in Papua Barat.

Regional Blueprint for Energy Transition

According to Jawa Satu Power, the mega-project exemplified how strategic innovation, robust partnerships, and adaptive management can surmount complex financial and logistical challenges in large-scale energy infrastructure. “A robust risk management system developed in early phases involving stakeholders proved the project able to mitigate the challenges, plan and execute any contingencies required for navigating the execution project process up to successfully finished,” its leadership noted.

The multinational structure, notably, became a strength, because it recognized “different business customs, communication styles, and decision-making processes among partners from Indonesia (Pertamina NRE), Japan (Marubeni, Sojitz), and other international entities.” Critical to success was “deploying highly skilled engineering and technical teams from different project stakeholders (owner’s team, EPC Contractor, GE Vernova as the main equipment supplier and other players) on-site to address issues as they arise,” combined with collaborative problem-solving and comprehensive contingency planning that enabled the project to adapt to shifting circumstances without compromising objectives.

For now, the project’s 25-year power purchase agreement with PLN creates a stable economic foundation that benefits all stakeholders. By providing “long-term revenue certainty for the Jawa Satu project, making it attractive to investors and facilitating financing,” the agreement enables competitive generation costs that help “keep consumer electricity rates affordable” across the Jawa-Bali grid, Jawa Satu Power said.

Meanwhile, community integration extends beyond economics through targeted local development. The project achieved a 21% Domestic Component Level during construction, exceeding national requirements, while ensuring “the majority of Jawa Satu’s current operations staff are Indonesian nationals,” it noted. Comprehensive training and capacity-building programs guarantee “Indonesian talent plays a central role in both the construction and long-term operation of the facility,” supported by [corporate social responsibility] initiatives, including “building educational facilities for nearby schools” that “invest in future generations and strengthen long-term community relationships.”

Finally, operational lessons from Jawa Satu’s deployment of cutting-edge technology reveal that “introducing very new, high-efficiency technology—such as the GE Vernova machines used here—can bring both significant performance gains and initial challenges common to first deployments,” Jawa Satu Power added. The key to sustained success involves maintaining “experienced technical experts on site, capable of performing rapid diagnostics and proactive maintenance” to “address early challenges quickly and sustain high levels of operational performance,” it noted.

Jawa Satu is now set to establish a replicable framework for emerging markets through its proven integrated FSRU-to-power model, successful public-private partnership structure, and decarbonization pathway, which demonstrate “how gas-fired power plants can evolve to support net-zero ambitions through hydrogen blending and CCUS readiness,” GE Vernova said. The model could prove particularly relevant for island nations seeking “flexibility and speed of deployment compared to traditional land-based LNG terminals” while maintaining advanced technology deployment standards for baseload and flexible power generation.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).