While conducting a comprehensive inspection on more than 2,000 of the reactor’s removable insert liner bolts during a Unit 2 planned outage at the Indian Point nuclear power plant, engineers identified issues with approximately 11% of them, requiring further analysis.

Some of the bolts—and the bars meant to hold them in place—were missing, while others were degraded to the point that replacement was required. Although the issues identified were said to have no impact on public health or safety, the revelation has alarmed many opponents of the plant who have been fighting its relicensing effort.

“This is the latest in a long series of incidents that raise deep concerns about the management, maintenance and equipment standards at this plant. While there is no immediate danger to public health and safety, this troubling news further validates the State’s ongoing investigation into the operations of this aging power plant and our position that it should not be relicensed,” New York Gov. Andrew Cuomo said in a statement following disclosure of the news.

Other recent problems at the plant have included a transformer fire that forced Unit 3 offline last May and the discovery of elevated levels of tritium in groundwater monitoring wells in February.

“New York State will continue to investigate every facet of the plant’s operations and safety preparedness while ensuring that these critical defects are addressed immediately,” Cuomo added.

Entergy Corp., owner and operator of the plant located on the Hudson River in Buchanan, N.Y., said the latest issues would be corrected prior to Unit 2 being returned to service. The work is expected to add cost and several weeks to the refueling and maintenance outage, which began on March 7.

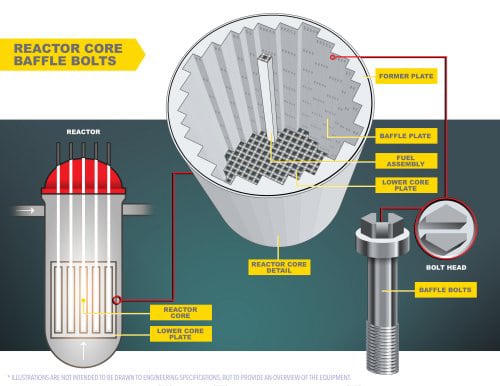

The inspections were conducted as part of Indian Point Unit 2’s “Aging Management Program,” which was implemented in connection with its license renewal. The program calls for an in-depth inspection of the reactor vessel every ten years; this was the first such inspection. The process included visual inspections, combined with ultrasonic inspections, where possible. The issues identified were with bolts on the face of the removable liner, rather than along the liner’s edge (Figure 1).

More than 350 inspections of critical equipment were conducted during the outage. The reactor containment area, reactor vessel, control rod mechanisms, coolant pump motors, and steam generators were all part of the testing and inspection regimen. Inspections were also performed outside the containment area on dozens of valves, turbine rotors, condensate storage tanks, and other equipment. Equipment was replaced on some of the control rod mechanisms, pipes, heat exchangers, steam condensers, and reactor coolant pump motors, according to Entergy.

“Safety is always our first priority, and the hundreds of inspections performed over the last few weeks demonstrate these programs work as designed,” said Larry Coyle, site vice president at Indian Point.

—Aaron Larson, associate editor (@AaronL_Power, @POWERmagazine)