Since the early 1970s, water-cooled power plants have installed fish protection technologies largely on a case-by-case basis with limited guidance from the U.S. Environmental Protection Agency (EPA). In 2004, the EPA published rules (the Rule) for implementing Section 316(b) of the Clean Water Act (CWA) at existing plants. The Rule uses national performance standards as a metric for measuring the effectiveness of compliance options. Those standards are: a reduction in impingement mortality of 80% to 95% and, in some cases, a reduction in entrainment of 60% to 90%, compared with a baseline.

The Rule is technology-based. All of the compliance options require an examination of intake design and operational measures to demonstrate that the protection of aquatic organisms will meet the performance standards. Most of the compliance alternatives require a detailed evaluation of alternative technological and/or operational measures to determine the feasibility, effectiveness, and cost of compliance. Previous articles in POWER (May 2004, January/February 2005, May 2005, and September 2005) have reviewed available technologies and the process by which they can be evaluated for possible application at cooling water intake structures (CWIS).

In this article, we examine the possible sources of injury and stress that fish encounter as they move through a CWIS and provide new evidence suggesting that prior assumptions about such experiences were incorrect. An outgrowth of these findings is strong evidence that one technology—the modified traveling screen with fish protection features—has the potential for wide-scale application for meeting the impingement mortality reduction standard (80% to 95%) in all types of water bodies and under a variety of hydraulic and environmental conditions.

Myth # 1: Intakes are vacuum cleaners

Consider first how fish actually enter cooling water intakes. Some people imagine intakes as giant vacuum cleaners, "sucking fish in" from their natural environment. There is no empirical data to support this belief. On the contrary, if one considers the behavior of fish and the way in which they naturally react to physical obstacles and hydrodynamic conditions in their environment, the possible manner in which fish interact with intakes becomes clearer.

It is generally assumed that for a fish to enter a CWIS, it must be in the area where the structure influences the plant flow. Figure 1 shows the flow streamlines at two CWIS on a major river. The yellow streamlines represent the flow in the river passing the CWIS. The barge deflector interrupts the flow in front of each intake, creating a gyre, or vortex, there. In this case, the area of influence of the CWIS is restricted to a small zone that only fish moving very close to the shoreline would enter.

1. Fish-friendly. Typical river water flow streamlines. The vortices (in blue) created by the barge deflector serve to limit the number of fish entering each intake. Source: EPRI

The fish most commonly "impinged" at CWIS swim in daily and seasonal patterns as they forage for food or move to spawning areas. Their movement may bring them close to a CWIS. Here, fish behavior comes into play. For a fish to avoid an intake, it must receive some type of stimulus, or cue, to trigger an avoidance response.

Within the range of velocities and other hydraulic phenomena occurring at most CWIS, such cues appear to be largely lacking. This is not surprising, given that the hydraulic conditions that fish experience at intakes are not substantially different from those they experience elsewhere. In most environments, fish are subjected to flow velocities from about 0.1 to 3.0 ft/sec. Similarly, turbulence is common to both normal and CWIS environments and is most pronounced in tidal estuaries and rivers.

Fish indeed respond to hydraulic conditions at a CWIS as they respond to any object in open water. Lacking any cues that would trigger an avoidance response, fish enter cooling water intakes freely. Once within the CWIS, they may or may not receive stimuli that would signal them to return to the source body of water.

Observations of fish within intakes indicate that most are capable of maintaining their position in the flow and are free to move about. Larger predatory species are known to favor screenwells, where prey can become concentrated upstream of screens. Why don’t smaller fish simply move back upstream out of the intake? Decades of studies of angled screens and louvers clearly demonstrate that most fish will, in fact, take cues from these technologies, follow them along in a downstream direction, and safely enter a bypass at the downstream terminus. Without physical and hydraulic cues to guide fish in this manner, many species seem to lack the impetus to move upstream out of intakes and instead maintain their position in front of the screens.

Recent advances in tracking technologies—hydroacoustics and dual-frequency identification sonar (Didson)—allow us to monitor fish movement and behavior in real time. We can now begin to understand the behavior of fish as they interact with intakes. Images of fish at a tidal river intake in Alabama captured by a Didson camera clearly show them moving freely in and out of a shoreline CWIS. With further research of this type, we should come to better understand how fish behave at intakes and perhaps identify improved ways to minimize impingement.

Myth # 2: Fish are attracted to intake screens

The term "impingement" conjures up an image of a fish hung up on a screen from which it is released only as the mesh clears the water surface. In fact, it often is assumed that impingement is the primary cause of mortality. Although it is clear that fish do interact with screens, video footage from tests of modified, traveling screens makes clear that the interaction is different when the screen is optimally designed and operated with fish protection in mind.

Surely, at CWIS whose screens are rotated infrequently and have no fish protection features, many fish can be trapped and suffocate or die later from injuries and stress. However, screens equipped with fish-lifting buckets and continuous screen rotation provide opportunities for fish to be collected and released with little injury or stress.

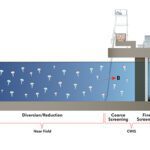

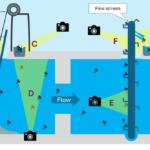

As it turns out, most fish long enough to be caught on a screen (at least 1 inch) can swim faster than the approach velocity to the screen. These fish can maintain position in front of the screen. Recent studies demonstrate that this behavior, coupled with the use of a continuously operating screen with fish buckets (Figure 2), provides the opportunity for fish to avoid experiencing "impingement" as many picture it.

2. Off the hook. New research indicates that fish actively avoid intake screens. Source: Siemens Water Technology

In 2006, the Electric Power Research Institute (EPRI) sponsored laboratory studies to quantify the survival of fish collected by a state-of-the-art, through-flow, modified traveling screen from Siemens Water Technologies (www.industry.siemens.com/water/en/). Ten species of fish commonly impinged at freshwater CWIS were evaluated: bigmouth buffalo, bluegill, channel catfish, freshwater drum, fathead minnow, golden shiner, hybrid bass, largemouth bass, white sucker, and yellow perch.

Tests were performed at screen approach velocities of 1, 2, and 3 ft/second. In each test, a group of fish was placed in a confined area upstream of the screen at a low approach velocity. The velocity then was increased to each of the three test values and the fish were observed behaving naturally. At the end of each test run, a crowder screen was deployed to encourage any remaining fish to enter the fish buckets and be removed. Fish collected by the continuously rotating screen were collected in a trough on the back side of the screen, just as they would be at a CWIS.

Discrete samples of the collected fish were taken at regular intervals during each trial, and each sample was held separately for 48 hours for the purpose of quantifying latent survival. In particular, the fish collected by the crowder screen were separated because they were least likely to experience true impingement. All tests were recorded on videotape to enable viewing of fish behavior in detail for the first time

Figure 3 shows a group of white sucker and golden shiner actively avoiding impingement on the traveling screens. Although behavior varied slightly among the 10 test species, the predominant response to the screen was avoidance. Fish maintained position immediately upstream of the screen; many fish entered the bucket (an area of reduced flow) and remained there until they were discharged into the collection trough.

3. Screen test. White sucker and golden shiner actively avoiding a traveling screen by swimming upstream (to the left). Courtesy: Alden Research Laboratory Inc.

The key finding of this study was that the 48-hour survival of all species at all velocities approached 100%. EPRI and Alden attribute these high survival rates to the ability of the test fish to exploit the improved fish protection features of the modified traveling screen.

The next logical question is: Are the results of the lab studies representative of survival that can be expected at an actual CWIS? Intuitively, one might expect that the lab fish would be more likely to survive than fish "in the field." After all, fish in the wild are exposed to disease, extremes of water temperature, debris, water pollution, and competition for food from other fish. Laboratory studies, by contrast, are conducted under conditions where the effect of natural stressors, particularly disease organisms, is typically more controlled.

In general, a greater range of survival values is reported from the field than from the laboratory. Average survival rates from field studies also tend to be lower than those observed in the laboratory. However, many of the field data—from studies conducted over the past 30 years—were from CWIS that had few, if any, fish protection features. If one selects from the survival database the results from facilities that incorporate fish-handling features (that is, lifting buckets and continuous screen rotation), reported survival rates are quite high. Using data from historical studies at such facilities, EPRI developed estimates of survival (see table) for a number of freshwater species commonly impinged at power plant CWIS.

Estimated survival rate of seven freshwater fish species commonly impinged on cooling water intake structures. Source: EPRI

These estimates indicate that the modified traveling screen indeed has the potential to meet the impingement mortality reduction standard in CWA Section 316(b). However, site-specific factors will impact the ability of a particular screen to meet the standard. Before making any full-scale retrofits, plant owners would be wise to conduct pilot-scale field studies to confirm the effectiveness of screens at their site(s). Regional studies of modified traveling screens in bodies of water with similar species and hydraulic and environmental conditions could be a cost-effective approach to verifying performance.

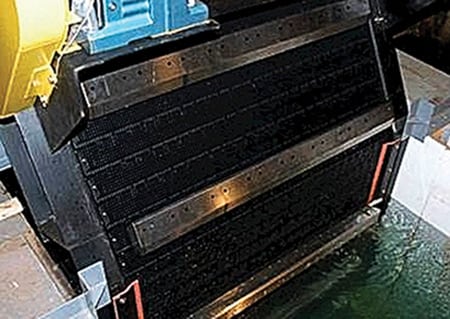

A number of new screen designs have entered the marketplace and are worthy of consideration for 316(b) compliance. Two that were tested in the laboratory or field in 2006 are shown in Figures 4 and 5. Both screens are equipped with buckets that give fish a quiescent area to swim in. Test results indicate survival rates as high as those measured for other modified screens. Visit the web sites of the screen manufacturers (www.geiger-gmbh.de/ and www.hydrolox.com) for more details.

4. One 316(b) compliance option. A rotating screen with fish protection features can safely return fish once they have entered a cooling water intake structure. Courtesy: Geiger GmbH

5. Another option. Other screen designs, like this one, also have proved effective. Courtesy: Hydrolox (formerly Intralox)

Myth # 3: High spraywash pressure kills

Historically, screen systems modified for fish protection have been equipped with a dual-pressure spray system: a low-pressure (5-10 psi) spray for fish and a high-pressure (60-100 psi) spray for debris. Often, the wash water from both sprays is returned to the body of water via separate troughs. The assumption underlying this approach—that fish would be injured or killed by high pressures or debris—has remained unchallenged for decades. Another assumption, made by the EPA as it developed the Rule, was that intake screens with dual-pressure spray systems would be widely used by plants as a compliance option. Yet it is clear that plants could substantially reduce their retrofit costs if a single wash/trough could be used.

As part of the aforementioned EPRI lab studies of modified screens, tests were conducted to quantify the survival rates of four species—bluegill, channel catfish, freshwater drum, and golden shiner—when subjected to a spraywash pressure of 60 psi. Survival after 48 hours was 100% for all four species. Similar lab studies were conducted for the screens at PSEG’s Salem Nuclear Generating Station in New Jersey. In this case, alewife were exposed to pressures of 0, 20, 40, 60, 80, and 100 psi. Survival of this fragile species was approximately 100% under all test conditions. These results raise doubts about whether the standard, dual-spraywash system is required.

Finally, at Salem, both washes and troughs are combined after leaving the screenhouse into a single return to the source body of water. Survival estimates were obtained for a diversion of this combined flow (from 12 screens) into a sampling pool. Despite the presence of heavy debris loads, the survival rates at this facility are some of the highest reported in the literature.

Myth # 4: Fish return systems kill

As with spraywash pressure, it has long been assumed that certain features of fish return systems are injurious to fish and increase mortality. Most return systems use troughs or pipes to convey fish from the traveling screens to the body of water from which they came. The features of those systems most often considered hazardous to fish include vertical and horizontal bends, high velocities in shallow sections, and turbulent discharges into the receiving water. Over the years, criteria for safe fish transport have been developed for the following system features: bend radius, minimum water depth, and maximum velocity.

There are many CWIS whose fish return system can be retrofitted to bring the facility close to compliance with the 316(b) impingement mortality reduction standard. Where the system can be designed to incorporate established criteria, this approach is recommended. However, at some facilities it is impossible to meet the criteria cost-effectively for any of several reasons, including limited space, existing use conflicts, property ownership issues, elevation restrictions, and safety and security issues.

In 2004, PSEG conducted a study to determine if the return system at Salem Station was injuring fish to the extent that it warranted modification. The concerns at this facility were over high velocities in the return line and a large hydraulic jump in the discharge pipe as the flow reenters the Delaware River.

The study was conducted in the laboratory. First, engineers built a three-dimensional model of the as-built system to determine the velocities and shear forces within it. Then they evaluated two free-fall alternatives for eliminating the hydraulic jump. Even in areas of maximum velocity and minimum depth, the shear stresses identified for all three designs were in the range of values reported in the literature as being noninjurious to fish.

The next step was to build a full-scale, sectional model of the return system (Figure 6) in the laboratory for testing with live fish. Again, the as-built design was tested along with two free-fall alternatives. Though the turbulence observed with all three designs appeared to be injurious to fish, zero latent mortality was the result of tests using relatively fragile alewife. Underwater video showed that the alewife immediately schooled as they entered the receiving pool and displayed normal behavior.

6. Safe and secure. This full-scale model of the fish return system at Salem Nuclear Generating Station was built to evaluate fish mortality. Courtesy: Alden Research Laboratory Inc.

What’s next?

Laboratory studies of traveling screens modified to include fish-handling features indicate that they are effective enough at collecting and returning even fragile species with a high survival rate to meet the 316(b) impingement mortality reduction standard at many facilities. The next step in realizing the full potential of the technology is to conduct pilot-scale studies at existing CWIS.

The results suggest that the most important design and operational parameters for fish survival are an appropriately shaped lifting bucket and continuous screen rotation. If screen approach velocity and spraywash pressure are truly not factors critical to fish survival, the opportunity exists to use an existing screen bay at a CWIS for the pilot study—to confirm that costly modifications to reduce velocities and pressures are unnecessary. Data from the studies also indicate that return systems are not as injurious to fish as previously assumed. If the CWIS does not already have a fish return system, a temporary facility that allows collection of fish for holding will suffice.

The ability to use a simple screen replacement as a prototype test facility affords plant operators the opportunity to assess—at full scale—newer screen designs that may offer extended life, improved debris-handling features, or other O&M features favorable to the conditions at their CWIS (water quality, biofouling, and corrosion, for example).

The authors encourage operators of existing CWIS to consider the pilot-scale approach to Section 316(b) compliance. Under this approach, you would propose to conduct a pilot-scale study as a condition of the National Pollutant Discharge Elimination System (NPDES) permit for your facility and commit to a complete technology retrofit in the next permit cycle—if the technology provides an acceptable impingement reduction level.

—E.P. Taft is president of Alden Research Laboratory and can be reached at ntaft@aldenlab.com or 508-829-6000 ext. 410. J.L. Black is an associate biologist at the company and can be reached at jblack@aldenlab.com or 508-829-6000 ext. 431. L.R. Tuttle is senior fisheries biologist and can be reached at rtuttle@aldenlab.com or 508-829-6000 ext. 492. Doug Dixon is senior project manager at EPRI and can be reached at ddixon@epri.com or 804-642-1025.