Finland is making significant strides in a trial run that will demonstrate the entire process for the safe disposal of spent nuclear fuel (SNF) at Onkalo on Olkiluoto Island—the world’s first permanent geological repository. Since the start of September, nuclear waste disposal specialist Posiva has successfully encapsulated and stored the first three canisters filled with non-radioactive test elements. The trial run, which is a crucial part of the disposal facility’s commissioning, is expected to conclude within the next year, paving the way for actual disposal activities to begin, likely in 2025 or 2026.

Construction work at Onkalo, formerly an underground research facility, has been ongoing since June 2004, following four decades of site investigations. Finland’s government granted a decision in principle for the repository in 2000. In 2015, after wrapping up a detailed design and conceptual phase, the government granted Posiva—a joint venture between utilities Teollisuuden Voima Oyj (TVO) and Fortum Power and Heat Oy—a construction license. Posiva submitted an application for an operating license in December 2021, and it expects it could be granted this year.

Engineering Finland’s Deep Geological Repository

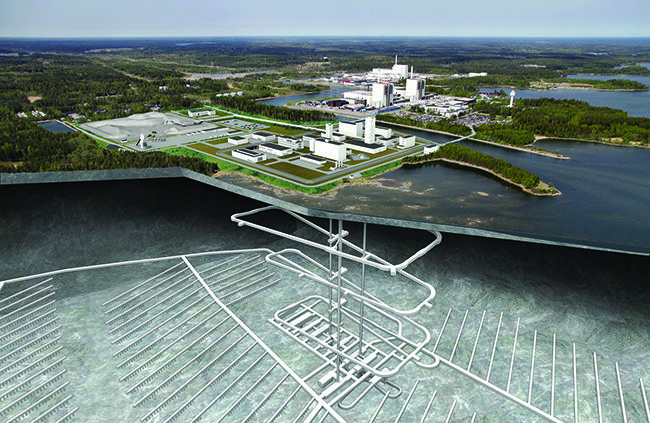

The Onkalo repository is being built at a depth of 400–430 meters (m, approximately 1,312–1,411 feet). It consists of “a spiral-shaped access tunnel, four vertical shafts (personnel shaft, canister shaft, and two ventilation shafts), tunnels, and technical rooms,” the company says. A key feature is the site’s encapsulation plant, where spent fuel will be safely sealed in disposal canisters. The plant, which began construction in 2019, is designed with “experience from fuel processing plants designed in different parts of the world,” Posiva noted.

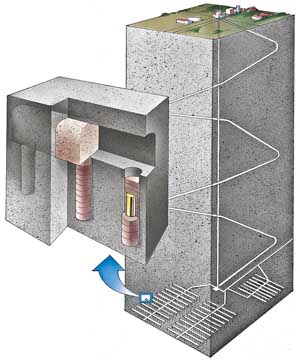

When final disposal operations are underway, SNF will be transferred from interim storage to the encapsulation plant, where it will be packed into copper and spheroidal graphite cast iron canisters designed to contain Finland’s boiling water reactor (BWR) and pressurized water reactor (PWR) spent fuel, totaling 6,500 tons of uranium. Inside the encapsulation plant’s underground rooms, fuel will be loaded into about 3,250 canisters within a heavily shielded fuel-handling cell featuring 1.3-m-thick concrete walls. Each canister will then be filled with argon gas, sealed with a steel lid, and topped with a copper lid secured by friction stir welding—utilizing the KBS-3 method developed in partnership with Swedish radioactive waste management firm Svensk Kärnbränslehantering AB (SKB)—and rigorously inspected for joint integrity.

Once sealed, canisters will be lowered by a specialized lift 430 meters into the crystalline bedrock, where they will be transported to 8-m-deep deposition tunnels surrounded by bentonite clay for permanent storage. For now, waste from the encapsulation plant will initially be transferred to TVO’s existing low- and intermediate-level waste (LILW) repository until a dedicated LILW repository is built.

|

|

The trial run, which began on Aug. 30, is a comprehensive large-scale test designed to validate the entire process of SNF disposal using non-radioactive test elements that simulate SNF (Figure 1). It will entail the storage of four main canisters and one backup, which will be stored in approximately 70 m of deposition tunnel, sealed with a final plug. By conducting the trial run, Posiva said it will evaluate the readiness of its systems, the precision of remote-controlled operations, and the facility’s overall safety. The company will also test emergency scenarios, such as retrieving a damaged canister back to the surface.

“We are ensuring that our equipment, systems, organization, expertise, as well as our procedures and guidelines, all work together seamlessly as a whole so that we can demonstrate our ability to carry out the disposal operations comprehensively and safely,” said Karri Osara, production director at Posiva.

As of Oct. 17, Posiva reported the first three canisters had been successfully transferred into storage at the encapsulation plant. The trial run kicked off with the assembly of a test canister and its secure transport of a test cask from TVO’s interim storage to Posiva’s encapsulation plant along a controlled route, employing procedures similar to those planned for regular spent fuel transfers. “The first two encapsulations were carried out using only weights. In this third trial, elements looking like actual fuel were packed inside the canister,” the company said.

However, the company has paused the trial before it begins the process for the fourth canister to “allow adjustments and extra testing to be made on the equipment.” The trial run’s next step will be to begin activities at Onkalo’s underground facilities to test the operation of the final disposal repository excavated in the bedrock.

Global Challenges and Innovations in Spent Nuclear Fuel Management

Finland’s strategic development of its Onkalo facility has set a model for the global nuclear industry, which has long grappled with SNF management. While waste management remains at the center of many debates about nuclear energy, the more than 400 nuclear power reactors in operation in 31 countries today produce about 430,000 tonnes of spent fuel, according to the International Atomic Energy Agency (IAEA). About 30% has already been reprocessed for recycling, and the remainder is “safely stored in either wet or dry storage systems ahead of eventual disposal in an underground repository or for future recycling,” it notes.

The coming wave of new reactors, including small modular reactors, driven by decarbonization, requires more concerted efforts to address SNF management responsibilities and other back-end liabilities, the IAEA said at a conference it convened in June 2024. The agency noted that developing deep geological repositories is a lengthy process, often hindered by societal and regulatory hurdles, which complicates timelines for secure long-term storage. Effective SNF management strategies require substantial sustained resources, flexibility to incorporate emerging technologies, and solid frameworks to sustain knowledge transfer across generations and ensure storage systems remain viable until final disposal solutions are implemented, it said.

|

|

For now, along with Finland, Sweden appears to be making tangible progress toward the construction of a deep geological repository (DGR) at Forsmark near Vattenfall’s nuclear power plant (Figure 2). Concluding 40 years of planning, Sweden’s government gave the project its green light in January 2022. In October 2024, a court granted SKB an environmental permit for the construction and operation of the facilities, and the company is now awaiting an approved safety analysis report from the Swedish Radiation Safety Authority before it can begin construction. Full-scale operations could begin by the mid-2030s. The $2 billion facility will eventually span 60 kilometers of tunnels, housing 6,000 copper canisters for up to 12,000 tonnes of SNF at a depth of 500 m, using the KBS-3 containment method developed jointly with Finland’s Posiva. SKB’s DGR and encapsulation plant at Clab will address storage needs for SNF from Sweden’s 12 reactors.

On Nov. 28, 2024, meanwhile, Canada’s Nuclear Waste Management Organization (NWMO), tasked with the nation’s long-term nuclear waste management, selected Wabigoon Lake Ojibway Nation (WLON) and the Township of Ignace in Ontario as host communities for its first deep geological repository for used nuclear fuel. This milestone, which follows a 14-year consent-based site selection process, marks a historic step for Canada. The project now enters the regulatory decision-making phase, including WLON’s Indigenous-led Regulatory Assessment and Approval Process (RAAP).

France’s Cigéo project received public utility status in 2022, with construction expected by 2035. Switzerland’s Nördlich Lägern DGR could begin operations by 2060, pending a 2024 license submission and public referendum. China is also making strides, while countries including Japan, Germany, and the UK are advancing site selection processes.

In the U.S., however, progress remains stalled following halted funding for the designated Yucca Mountain repository. So far, the U.S. Department of Energy’s unmet obligation to permanently dispose of SNF has burdened taxpayers—without congressional oversight or appropriations—with “rapidly growing liability cost payouts that are now estimated at $51 billion and will likely again soon increase substantially,” said Lake Barrett, former principal deputy director for the Office of Civilian Radioactive Waste Management, during a recent Congressional hearing.

“Thousands of temporary large spent fuel canisters, that the taxpayers have to pay for, are being built across the country being stranded on our seasides, lakes, and rivers where they were never intended to be. Although temporarily safe, these serve no useful societal purpose other than compensating for the federal inability to perform and are blocking the reuse of shutdown reactor sites,” he said. “Advanced nuclear technologies, such as new reprocessing approaches, may somewhat be able to assist in geologic disposal, but they are not a substitute for a geologic disposal facility.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).