piping

-

Coal

How Innovative Technology Is Making Waves in the Power Generation Industry

Is dual-containment pipe leak detection or effluent compliance keeping you awake at night? There are smart, sustainable solutions to save time and money. Regulators, investors, media, and the general public—as well as the power generation industry itself—are all keenly aware of protecting health and safety in the process of generating power. Coal ash contains toxins, […]

-

Press Releases

Zetec introduces ElbowFlex scanner for quick, manual ultrasound examinations of pipe elbows

SNOQUALMIE, Wash. (March 9, 2021)—Zetec Inc., a global leader in nondestructive testing (NDT) technology, today introduced the ElbowFlex™ scanner for quick, manual ultrasonic inspections of pipe elbows in oil and gas, petrochemical, power generation, manufacturing and other industrial applications. ElbowFlex is the perfect tool for measuring wall thickness and detecting flow accelerated corrosion on elbows […]

-

Gas

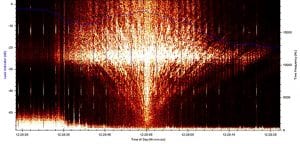

How to Clean Natural Gas Piping with Gas Blows

Prior to placing newly installed natural gas piping and valves in service, systems must be properly cleaned to remove potentially damaging foreign material that is inherently left behind during construction

-

Press Releases

PSRE Co. Expands Market Presence in Middle East and North Africa

February 6, 2019 – PSRE Co., a developer of smart simulation and sizing tools for every piping and equipment engineer/designer, is pleased to announce the expansion of its market presence for the PASS Software Suite in the Middle East and North Africa . PSRE has signed a distribution agreement with Adams Consultancy & Infrastructure (Adams […]

-

O&M

Implementing an ASME Covered Piping Systems Program

Power plant piping with a nominal pipe size of four inches or larger that carries steam or water operating at greater than 750F or 1,025 psi is considered a “covered piping system.” That means the

-

O&M

Equipment Showcase: Valves, Piping, and Fittings

Proper valves, pipes, and fittings are important for successful operation of power generation facilities. This equipment includes products with versatile designs to establish effective joining and sealing

-

O&M

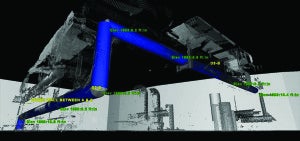

3-D Laser Scanning of Nuclear Plant Piping Systems Reduces Radiation Exposure

It’s no secret that high-radiation areas are scattered throughout nuclear power plant facilities. The challenge is getting work done in those areas while keeping exposure to workers as low as possible. On

-

O&M

Grooved Mechanical Piping Offers a Versatile Pipe-Joining Alternative

Two of the most important elements in any construction or upgrade project are safety and speed of completion. While one way to increase safety is to eliminate hot work whenever possible, the reality is that welding is necessary for many tasks around a power plant. However, one area where welding may not always be required […]