|

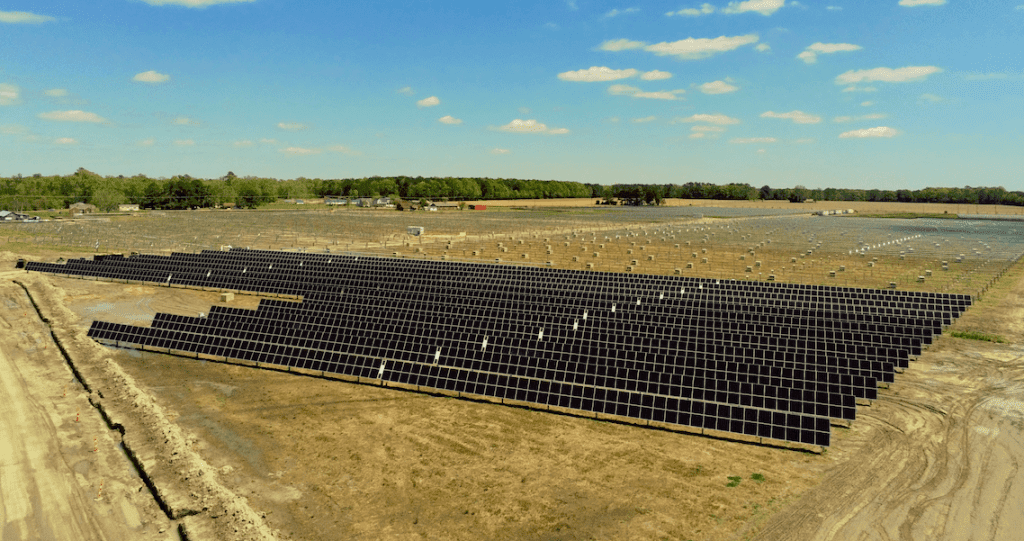

A long-dormant coal mine waste site in Pennsylvania has new life, providing solar power to the local community thanks to a groundbreaking tracking system enabling installation across challenging terrain.

Companies developing renewable energy projects know those installations can bring even more value when built on a brownfield site. The ability to repurpose a once-industrial or other area and transform it into a sustainable energy hub, reclaiming the land while providing needed power, can support the surrounding community while providing economic and environmental benefits.

A coal mine waste site in Pennsylvania had sat abandoned for 80 years. Transforming the site into a renewable energy installation would be challenging, not only due to remediation work, but also because of the terrain. It also called for convincing local residents the project would be beneficial, not disruptive, and would consider the impacts of drainage from the site.

Overcoming those challenges made completion of the Sarish Solar Project, a 26-MW solar farm in Burgettstown, Pennsylvania, even more rewarding. Robert Stoever, senior vice president of engineering, procurement, and construction at Ampliform, the project lead, described the site as “a challenge from a cost and compliance standpoint,” and said parts of the site “looked like the moon” due to the soil acidity not allowing ground cover to grow. The extreme terrain made Sarish “economically unbuildable” by conventional standards.

“The site was extremely difficult regarding siting a PV [photovoltaic] plant and establishing proper ground cover without spending an insane amount of money,” Stoever said, noting that terrain-challenged sites are inherently risky. Wet ground and steep slopes post dangers; the Ampliform team knew a primary challenge was to avoid costly grading and erosion risks as much as possible while maintaining project viability. The site would require the use of innovative equipment that would work in a less-than-ideal setting for a solar farm.

“The Sarish site was a former coal strip mine inactive for some 80 years, with steep 30% slopes, rock ledges, and acidic soil requiring 80 tons of lime for treatment,” said Rahul Chandra, head of Product Marketing for Nevados, a California-based company that provides equipment for utility-scale solar power installations. “All of this meant that it was difficult to do anything with the site including using traditional solar technologies to build a solar plant. It was only with the Nevados system that it became economically feasible. Grading the site to use traditional trackers would create major erosion issues, especially due to short growing seasons and difficulty establishing ground cover.”

|

|

1. The challenging terrain of a former coal mine waste site in Pennsylvania called for an innovative tracking system in order to build a solar power installation on the land. Courtesy: Nevados |

The Sarish Solar Project demonstrates how a challenging landscape (Figure 1) can still be utilized for a renewable energy project, in this case turning what some would consider an unbuildable site into an economically viable solar farm. Sarish showcases the potential of Nevados’ TRACE All Terrain Tracker (ATT), technology that supports solar energy development, enabling high performance on difficult terrain and earning the project a POWER Top Plant Award in the renewable energy category.

Ampliform Leads the Project

Ampliform, a Pennsylvania-based utility-scale solar and energy storage developer, developed and owns the Sarish project, and was the lead on the solar farm’s execution. Ampliform is backed by equity investors Jones Family Office and the George Kaiser Family Foundation, and plans to develop 10 GW of solar projects across North America by 2027. The company said its team of energy industry veterans focuses on delivering long-term value to communities, landowners, utilities, renewable energy consumers, and investors.

Pennsylvania-based Terra Works was the local civil contractor responsible for mechanical installation. The company—though new to solar—had extensive experience in civil and conservation construction. Terra Works pushed the boundaries for solar installation at 20% slopes, and has said it wants to take it further to 26% slopes on its next project with Nevados.

The project was first presented to local officials in early 2023. The Sarish site became operational in the second quarter of 2025. Chandra said the cost of the project could not be disclosed, but noted it took advantage of maximum tax credits from the Inflation Reduction Act (up to 55%), including the Energy Community adder and incentives for the use of domestic materials.

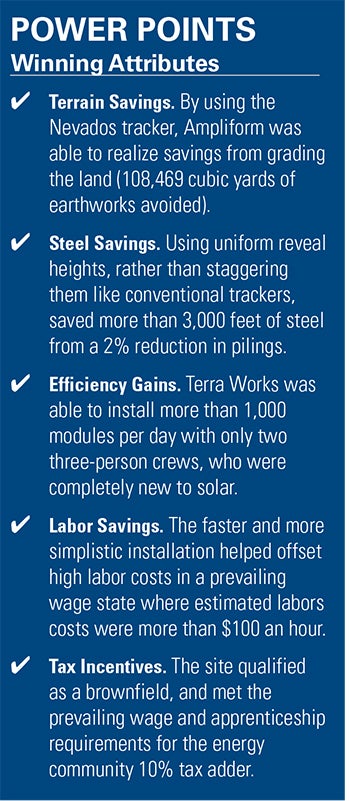

“Pennsylvania’s prevailing wage laws added labor cost pressure to an already challenging site. With the Nevados system, they were able to overcome the increased cost of prevailing wage labor with a system that was faster to install,” he said. Chandra noted that some of the main advantages gained by using Nevados’ ATT system included:

- Allowing construction on 20% slopes with zero site grading, avoiding more than 108,000 yd³ of soil disruption.

- Saving more than 3,000 feet of steel via consistent pile reveal heights, a 2% reduction in pile steel density across the site.

- Enabling rapid installation by a team with no prior solar experience—up to 1,000-plus modules per day with just two, three-person crews. The modules were 655-W models from Canadian Solar.

- Supporting pre-assembly for faster install and lower labor costs.

- Qualifying the project for additional IRA tax credits with domestic content.

“Do you know what it’s like to try and control erosion for a built project?” said Stoever. “Very difficult and costly. With a smart civil design, and a great all-terrain tracker, the risk of post-construction erosion is severely reduced.”

Terra Works, in a document detailing the project, described the ATT installation process as “highly systematic and repeatable. The system’s comfortable tolerances, excellent quality control, and precise engineering enabled rapid assembly and installation.” The company said it surpassed expectations by installing “up to 120 piles per day, with only 7% requiring pre-drilling due to rocky conditions.” The company said that by the end of the project more than 1,000 modules were installed each day, with work done by no more than three-person crews.

Terra Works, in a document detailing the project, described the ATT installation process as “highly systematic and repeatable. The system’s comfortable tolerances, excellent quality control, and precise engineering enabled rapid assembly and installation.” The company said it surpassed expectations by installing “up to 120 piles per day, with only 7% requiring pre-drilling due to rocky conditions.” The company said that by the end of the project more than 1,000 modules were installed each day, with work done by no more than three-person crews.

Terra Works’ team of 40 union carpenters adapted quickly to the Nevados system. “The intuitive design and support from Nevados made it much easier,” said Ryan W. Miles Sr., president of Terra Works. “The information that’s provided, the level of detail and constant shipping communication, were all top-notch. I was able to look at something on a PDF, go out to the field, and feel comfortable enough to tell somebody what to do. You rarely find that in anything.”

The builders said that Nevados’ pre-assembly features and ability to conform to the landscape streamlined the installation process and reduced the need for heavy equipment. The process also minimized environmental disruption.

“The Nevados system is perfect for pre-assembly of the cassette [torque tube and modules] due to the discontinuous torque tube,” said Stoever. “The ability to pre-assemble is built into the Nevados design. It’s a game changer.”

Controlling Costs

Stoever said Nevados’ ATT simplified the 40,000 module installations, accelerated assembly, and reduced labor hours. The groups said that was crucial to control costs for the project, particularly with Pennsylvania’s prevailing wage rates of up to $110 an hour for electricians.

Terra Works, by avoiding much of the grading and by working with the natural landscape, reduced soil disruption and reseeding efforts. The company’s team was able to close the pond and basin early, fill them in, and build over them to speed the installation. “This site would have been very difficult and costly had we not used the Nevados system,” Stoever said. “On a site like Sarish, it’s important to severely reduce the amount of grading and adapt the tech to the site, rather than grade out the site and adapt the site to the tech. When you cut and fill the soil, you need to establish/reestablish grass. This is problematic given the short spring and fall growing seasons. There are a lot of issues that people don’t think about regarding cut and fill.” Stoever said remediating erosion can cost millions of dollars and lead to “nightmare” scenarios.

“The ability to get conservation to close off ponds, reseed grass, and sign off on permits—that’s a big deal. Some project buyers would demand that conservation is signed off before the project fully changes ownership,” said Stoever, who noted that Ampliform needed an innovative approach to avoid costly grading and ensure a viable, safe, and efficient solar installation.

The project principals said that unlike traditional systems that would require extensive grading to achieve 5% to 8% slope tolerances, Nevados’ ATT allowed for Ampliform to reduce grading from the existing 30% slopes down to their preference of only 20%. “With Nevados, we could keep the high slopes and undulations on site. That saved a lot of pain and suffering,” said Stoever. “My mechanical contractor said they are able to go even steeper—up to 25% slope—for the next projects.”

—Darrell Proctor is a senior editor for POWER.